Reuse and regeneration method of dye solution in dye-sensitized solar cell manufacturing process

A technology of solar cells and dye solutions, applied in photosensitive equipment, photovoltaic power generation, etc., can solve the problems of waste of dyes and solvents, high cost of dyes and dye solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

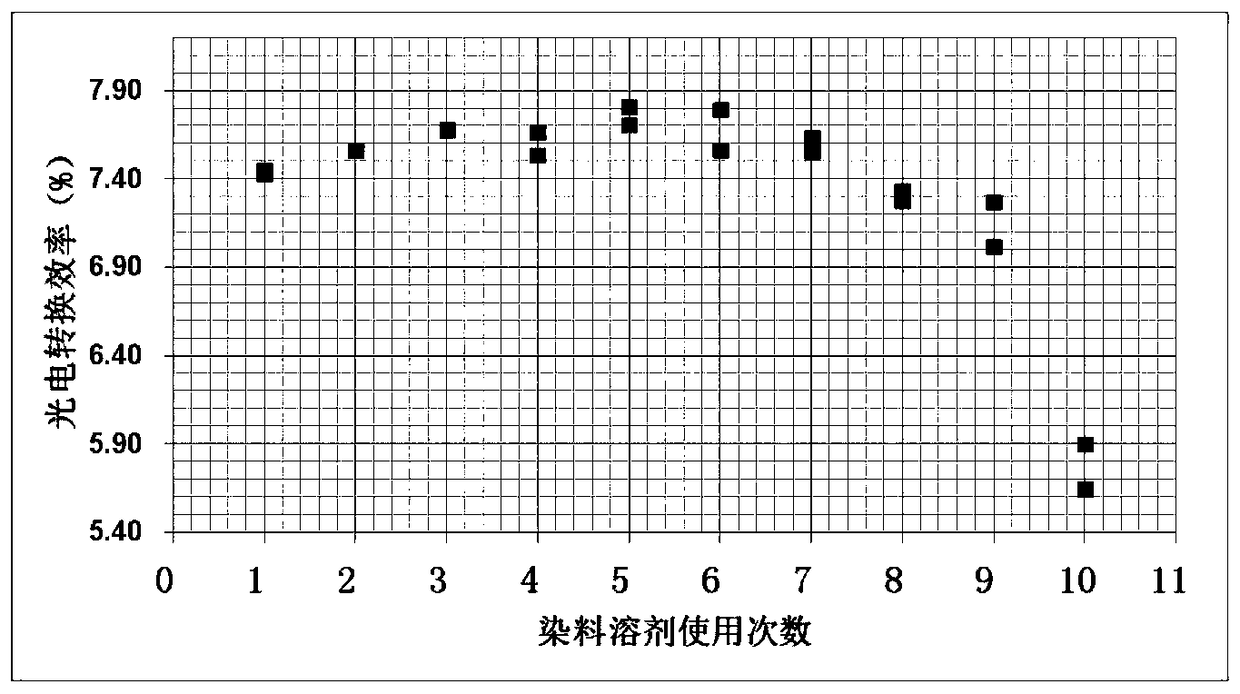

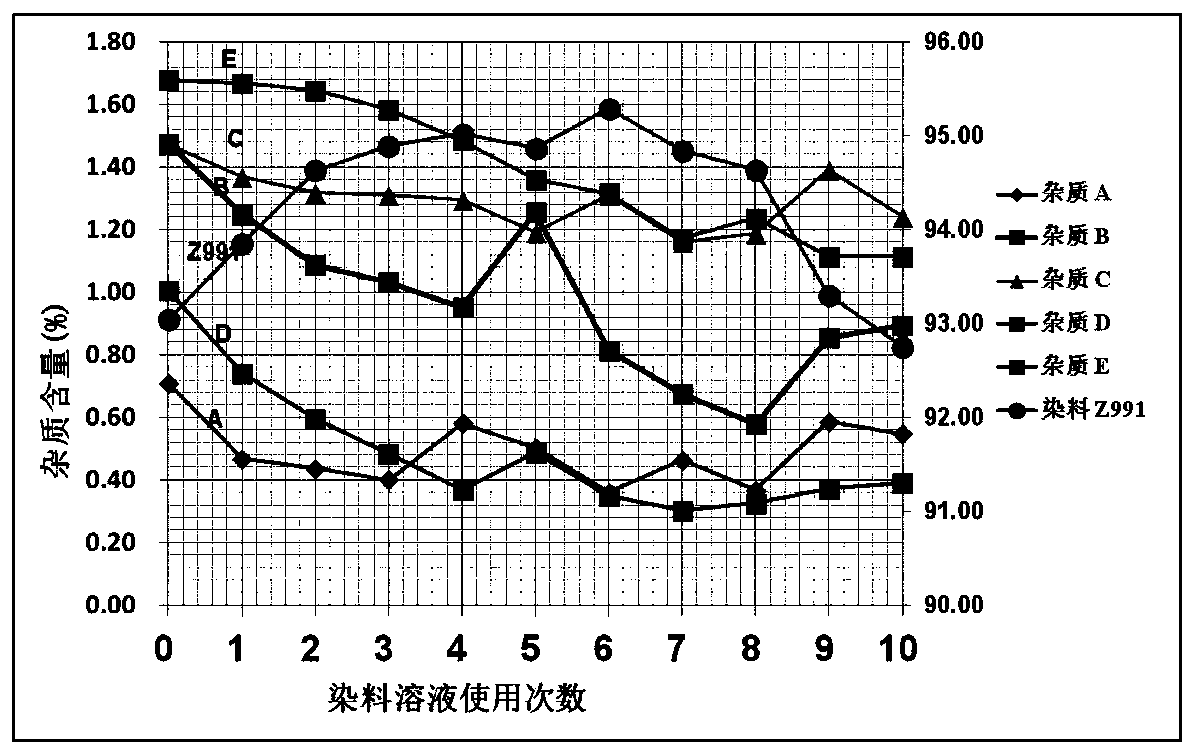

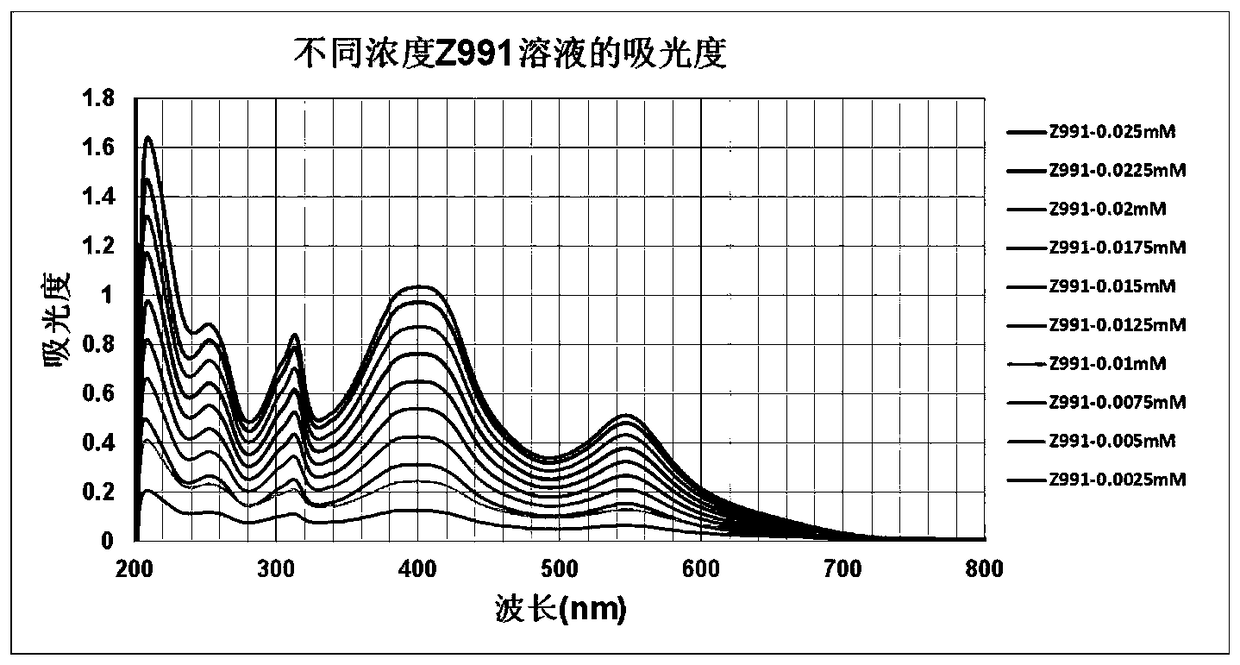

[0040] Take 0.28g of Z991 (purity is 93%, provided by the Green Photoelectric Conversion Technology Project R&D Department of Shanghai Institute of Ceramics, Chinese Academy of Sciences) dissolved in a mixed solvent of acetonitrile and tert-butanol (1 / 1, volume ratio), fully stirred Let it dissolve completely. Then add 0.022g DPA (co-adsorbent) and stir to form a 1L homogeneous mixed solution containing Z9910.2mM and DPA0.1mM after completely dissolving.

[0041] TiO in dye-sensitized solar cells 2 After the electrodes were printed on the surface of FTO by screen printing, they were sintered at 500 °C, Til 4 After processing and continuing to sinter, soak in the dye solution as described above for 48 hours, remove and clean with acetonitrile for later use. In the battery assembly, carbon is used as the counter electrode, and the electrolyte solution composed of ionic liquid, iodine and solvent is used, and a complete dye-sensitized solar cell can be assembled by standard met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com