Sleeve wrench special for disconnecting switch moving contact overhaul

A technology of isolating switches and moving contacts, applied in switchgear, electrical components, etc., can solve the problems of poor contact of conductive arms, heating of equipment joints, difficulty in operation and disassembly, etc., to achieve convenient material acquisition, reduce work intensity, and avoid moving contacts. Effects of head surface and thread damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

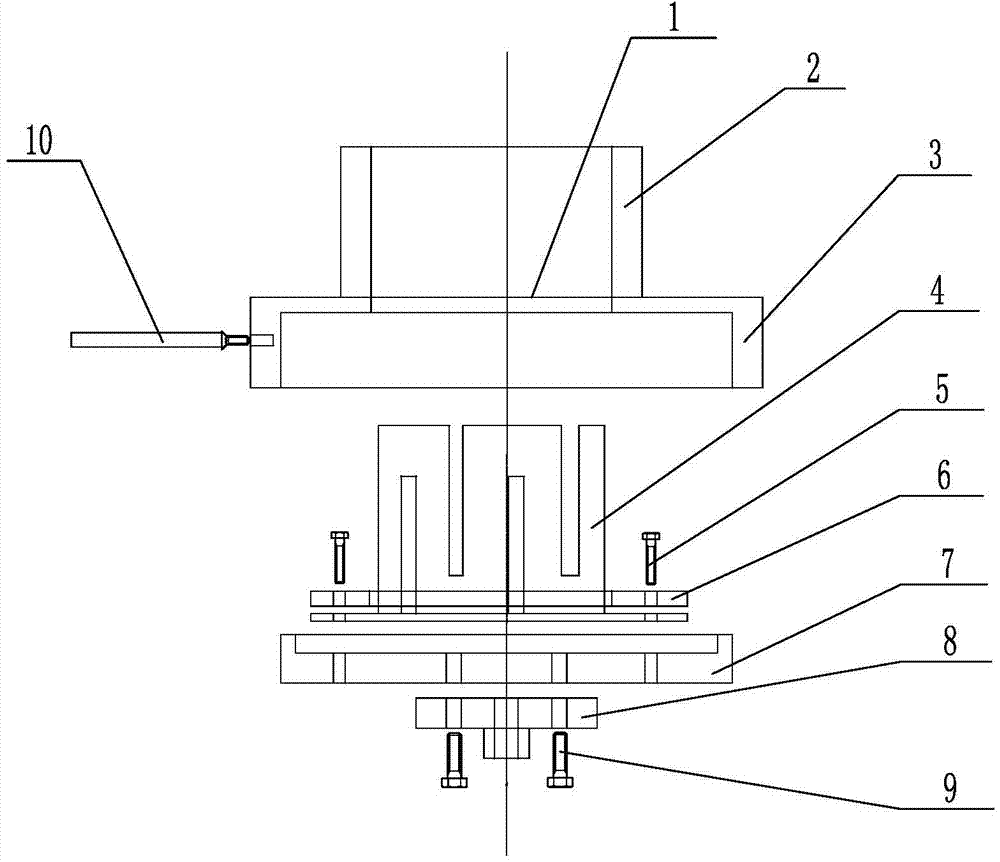

[0021] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

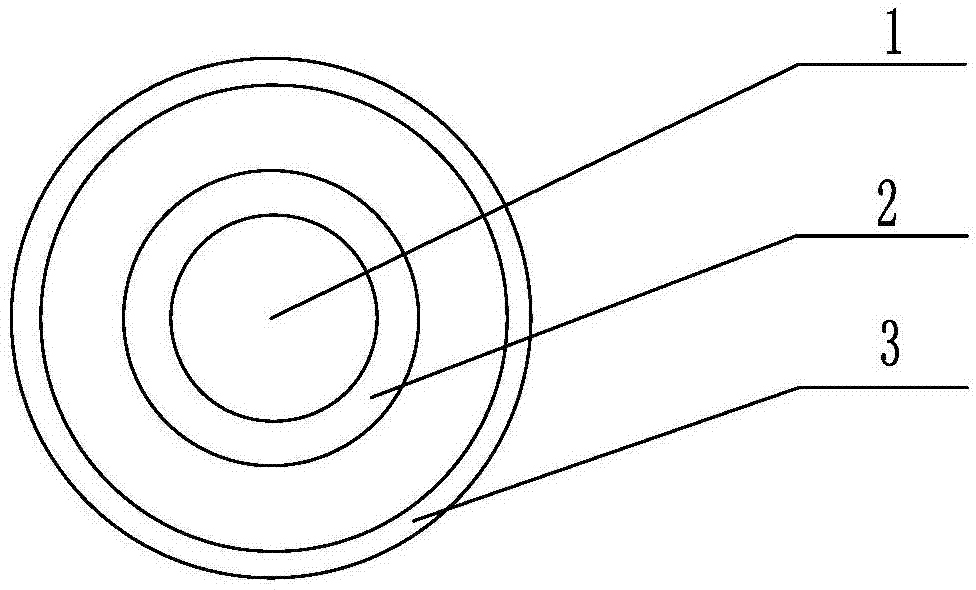

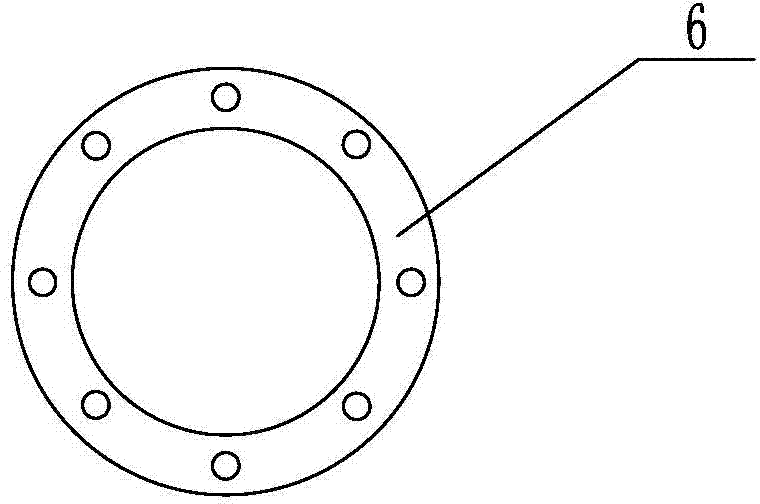

[0022] Such as Figure 1-Figure 5 As shown, the isolating switch moving contact special set for maintenance of the isolating switch according to the present invention includes a fixed seat 1, a fixed seat handle 10 is arranged on one side of the fixed seat 1, and a plastic ferrule 4 is closely attached to the fixed seat 1, and the plastic ferrule 4 A pressure plate 6 is arranged on the top, and the plastic ferrule 4 is fixed in the fixed seat 1 through the embedded chassis 7 at the bottom of the fixed seat 1, and the bottom of the embedded chassis 7 is provided with a special fixed plate 8 for a torque wrench.

[0023] The fixed seat 1 includes a first fixed seat 2 and a second fixed seat 3 connected into an integral structure, the first fixed seat 2 is arranged on the upper end of the second fixed seat 3, and both the first fixed seat 2 and the second fixed sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com