Special device for dismantling the clamping spring of the isolating switch ejector rod

A technology of clamping springs and special devices, which is applied in the direction of switchgear, electrical components, etc., can solve the problems of equipment precision reduction, injury, damage, etc., and achieve the effect of reducing operation intensity, improving efficiency and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

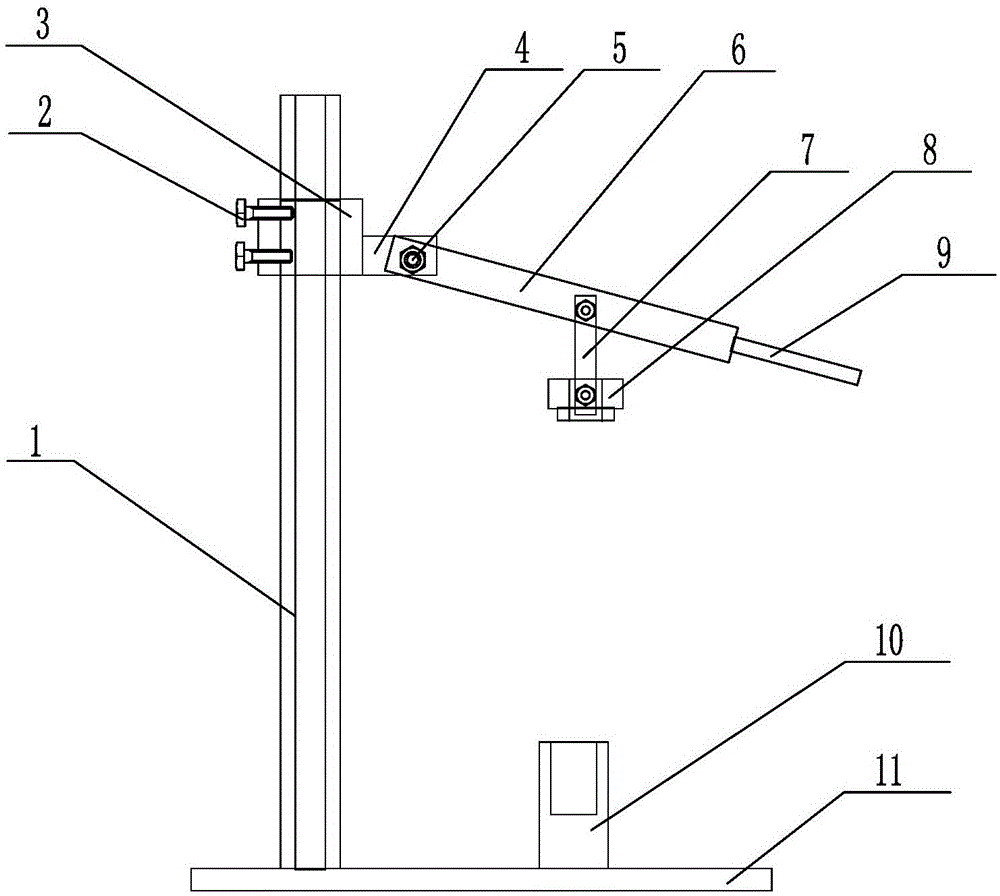

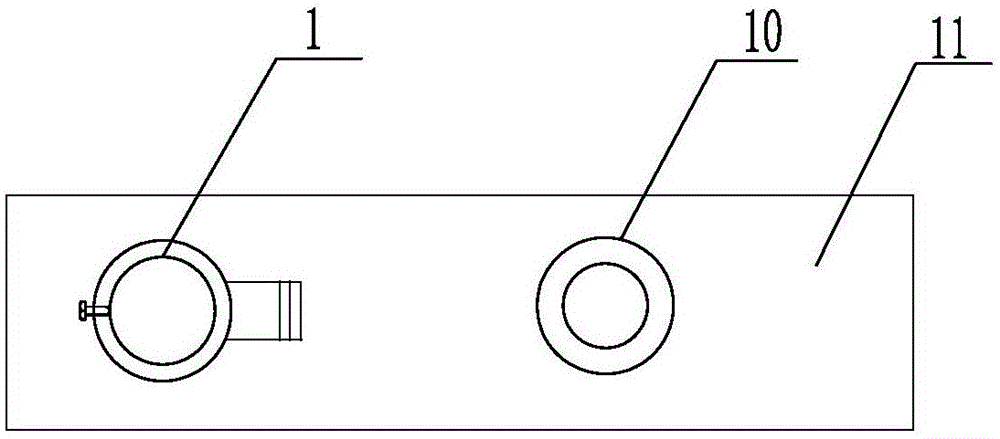

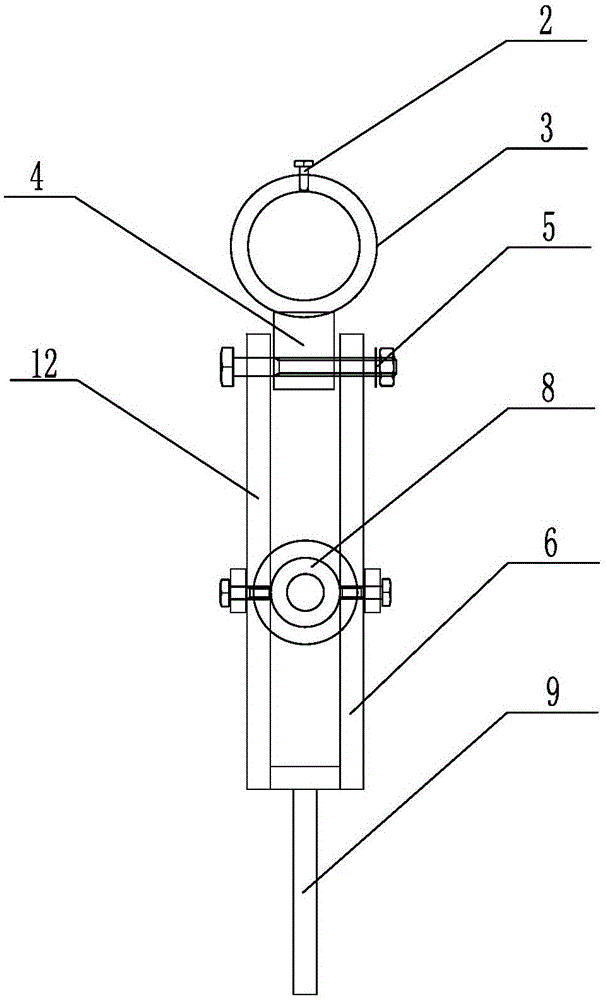

[0020] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0021] Such as Figure 1-Figure 3 As shown, the special device for disassembling the clamping spring of the isolating switch ejector rod according to the present invention includes a base 11, one end of the base 11 is provided with a supporting column 1, the other end is provided with a clamping spring ejector rod seat 10, and the upper end of the supporting column 1 is provided with a pressure arm The fixed sleeve 3 and the pressure arm fixed sleeve 3 are equipped with a connecting lever 4 on one side, and the connecting lever 4 is connected to the pressure arm 6 through the movable shaft 5. The front end of the pressure arm 6 is provided with a pressure arm handle 9, and a pair of snap ring connecting plates are mounted on the pressure arm 6. 7. The lower part of the snap ring connecting plate 7 is connected to the snap ring 8 .

[0022] Wherein, the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com