Spiral food heating, cooling or drying device and application thereof

A drying device and spiral technology, applied in the field of cooling or drying device and food heating, can solve the problems that the device cannot be used directly and the application is limited, and achieve the effect of reducing energy consumption, improving drying efficiency and prolonging service life of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Device Preparation (Design) Example

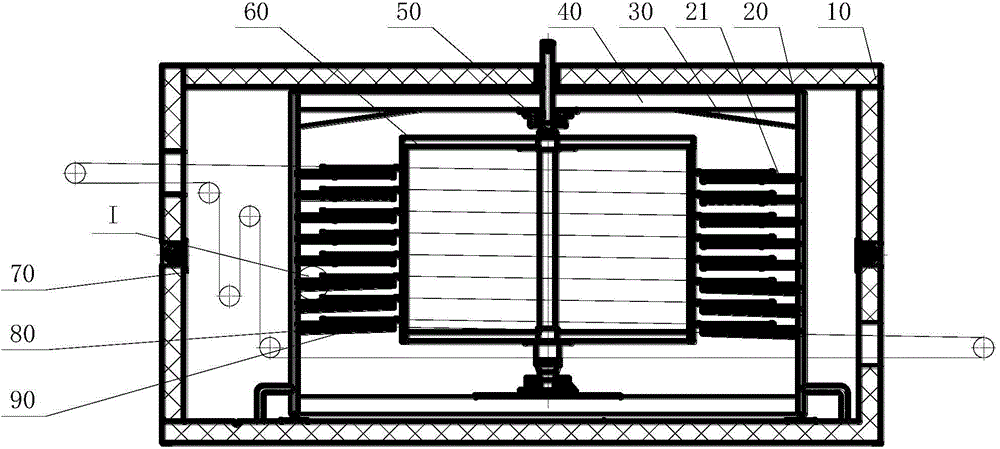

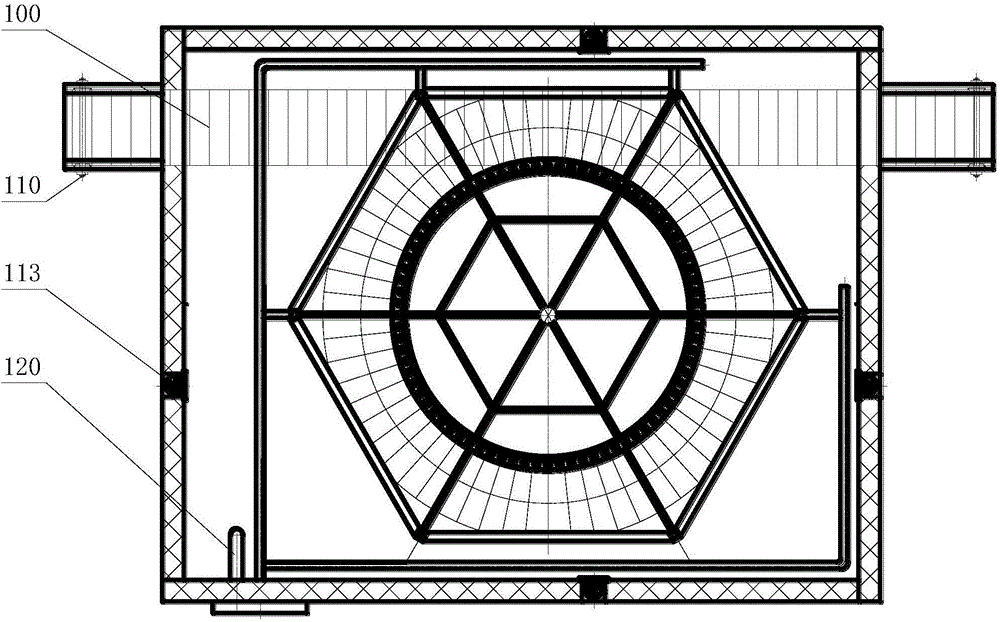

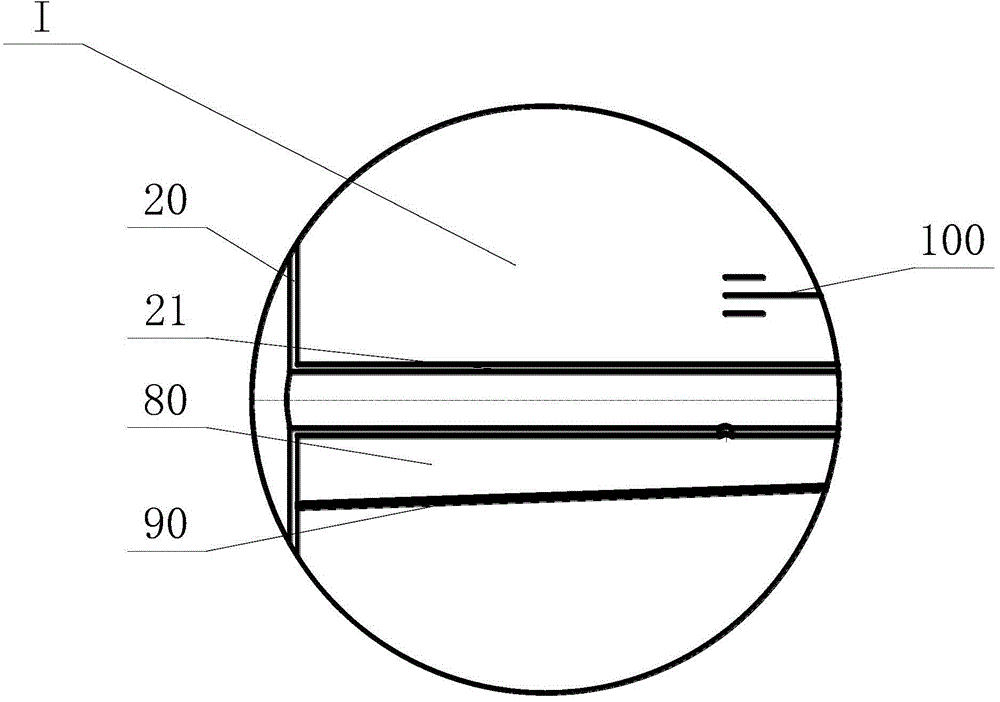

[0023] Depend on figure 1 and figure 2 As shown, a spiral food heating, cooling or drying device includes a thermal insulation storage body 10 (the thermal insulation storage body can be connected with an external air-conditioning system or an adjustable heating system) and a single screw conveying device, which includes a horizontal Rod 40, rotating hub 50, spiral tower 60, temperature sensor 70, conveying mesh belt 100, tension wheel 110 and drainage groove 120, it is characterized in that it also includes fluid pipeline main pipe 20, fluid pipeline branch pipe 21, arc cover plate 30. Condensed water deflector 80 , condensed water deflector bracket 90 and exhaust fan 113 . The rotating hub 50 is connected with external power, and the spiral tower 60 is rigidly connected with the rotating hub 50; the fluid pipeline main pipe 20 is provided with an interface communicating with the external medium, and the fluid pipeline...

Embodiment 2

[0026] Embodiment 2 Application Mode Example 1 (Application of the device of the present invention in the heating and steaming process in rice cake processing)

[0027] The spiral food heating device constructed in Example 1 is used for steaming rice cakes with an output of 625Kg / h, the medium is saturated steam at 120±5°C, and the heat supply is about 1.95×10 5 KJ / h. The rotating hub 50 is driven by an external motor, and the rotating hub 50 drives the spiral tower 60 to perform a rotating motion, and the spiral tower 60 drives the conveying mesh belt 100 to perform a spiral motion through friction transmission. Saturated steam with a temperature of 120±5°C is passed into the main pipe 20 of the fluid pipeline, and the flow rate is about 90Kg / h. The steam is sprayed directly onto the rice cake from the evenly distributed pores on the branch pipe 21 of the fluid pipeline to ensure uniform contact between the steam and the material. Temperature control device, the temperature ...

Embodiment 3

[0028] Embodiment 3 Application Mode Example 2 (Application of the cooling process of the device of the present invention in rice cake processing)

[0029] Adopting the spiral food cooling device constructed in Example 1, when used for cooling processing of rice cakes with a yield of 625Kg / h, the medium is cold air at 10±2°C, and the cooling capacity is about 1.6×10 5KJ / h. The rotating hub 50 is driven by an external motor, and the rotating hub 50 drives the spiral tower 60 to perform a rotating motion, and the spiral tower 60 drives the conveying mesh belt 100 to perform a spiral motion through friction transmission. The cold air with a temperature of 10±2°C is passed into the main pipe 20 of the fluid pipeline, and the cold air is directly sprayed onto the rice cake from the evenly distributed air holes on the branch pipe 21 of the fluid pipeline to ensure that the cold air is in uniform contact with the material. The temperature is maintained at (10±2)°C, tested by a multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com