Motorcycle tire

一种摩托车、轮胎的技术,应用在摩托车轮胎、摩托车、轮胎零部件等方向,能够解决抓地力干路性能变差等问题,达到大刮扫效果、提高湿路性能和干路性能、大接地面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

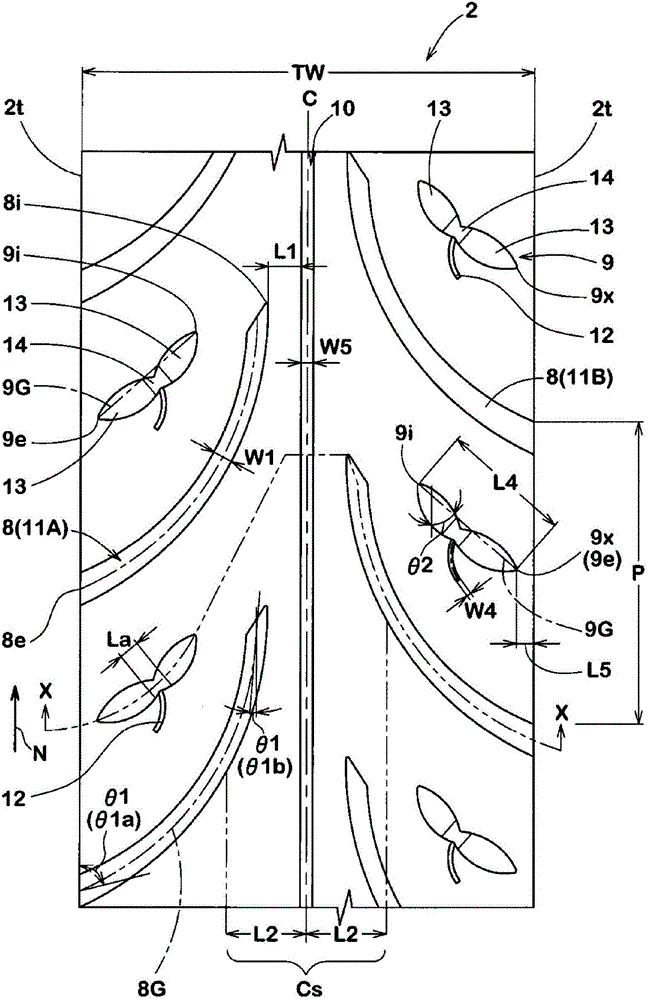

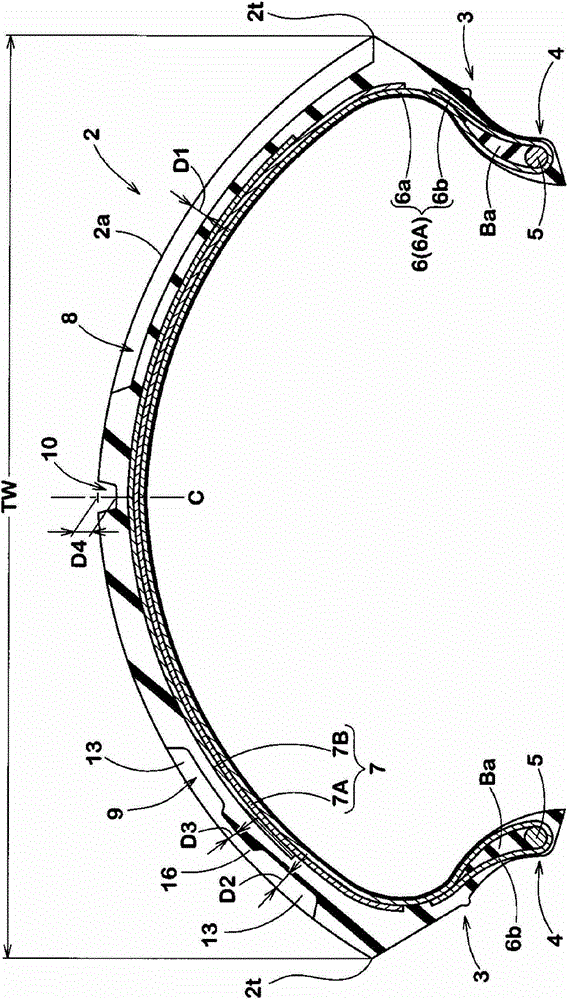

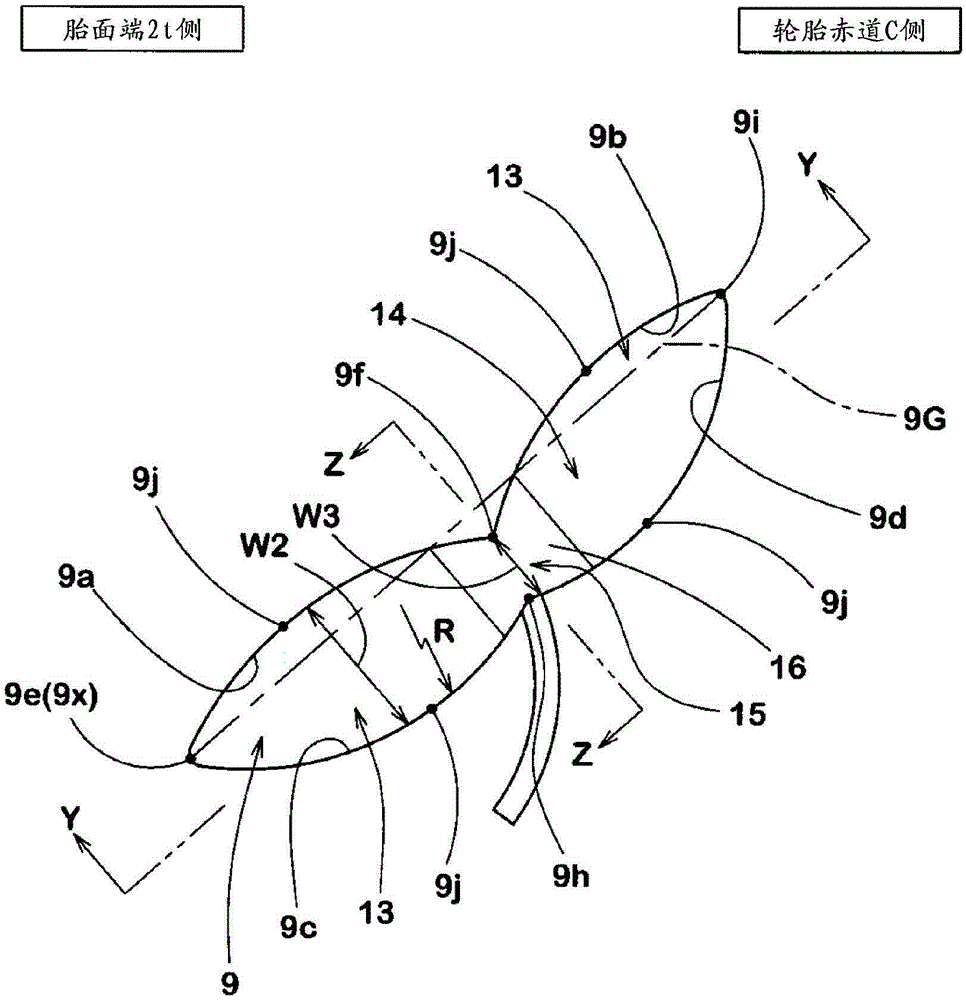

[0061] In order to confirm the effect of the present invention, the figure 1 The basic pattern and the 90 / 90-1050J motorcycle tires based on the specifications in Table 1 were tested. In addition to the grooves listed in Table 1, the groove width and angle of each groove are as follows: figure 1 shown. In addition, the main common specifications and test methods of each tire are as follows.

[0062] Tread width TW: 91mm

[0063] Groove depth of the main inclined groove: 5.5mm

[0064] Groove depth of shallow groove: 2.7mm

[0065] Groove depth of gradually increasing part: 5.2mm

[0066] Groove depth of central main groove: 5.5mm

[0067] Groove depth of fine groove: 1.0mm

[0068]

[0069] Each test tire was mounted on all the wheels of a motorcycle (displacement: 50 cc) under the following conditions. In addition, the test driver drives on the test track on the asphalt road with a water depth of 0.5 mm to 2.0 mm and the test track on the dry asphalt road, and compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com