Pressure dragging layering fracturing device

A technology of layered fracturing and dragging under pressure, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of difficult positioning of downhole tools, long construction period, and inability to rotate, etc., to reduce The effect of reducing the risk of string jamming, shortening the construction period, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

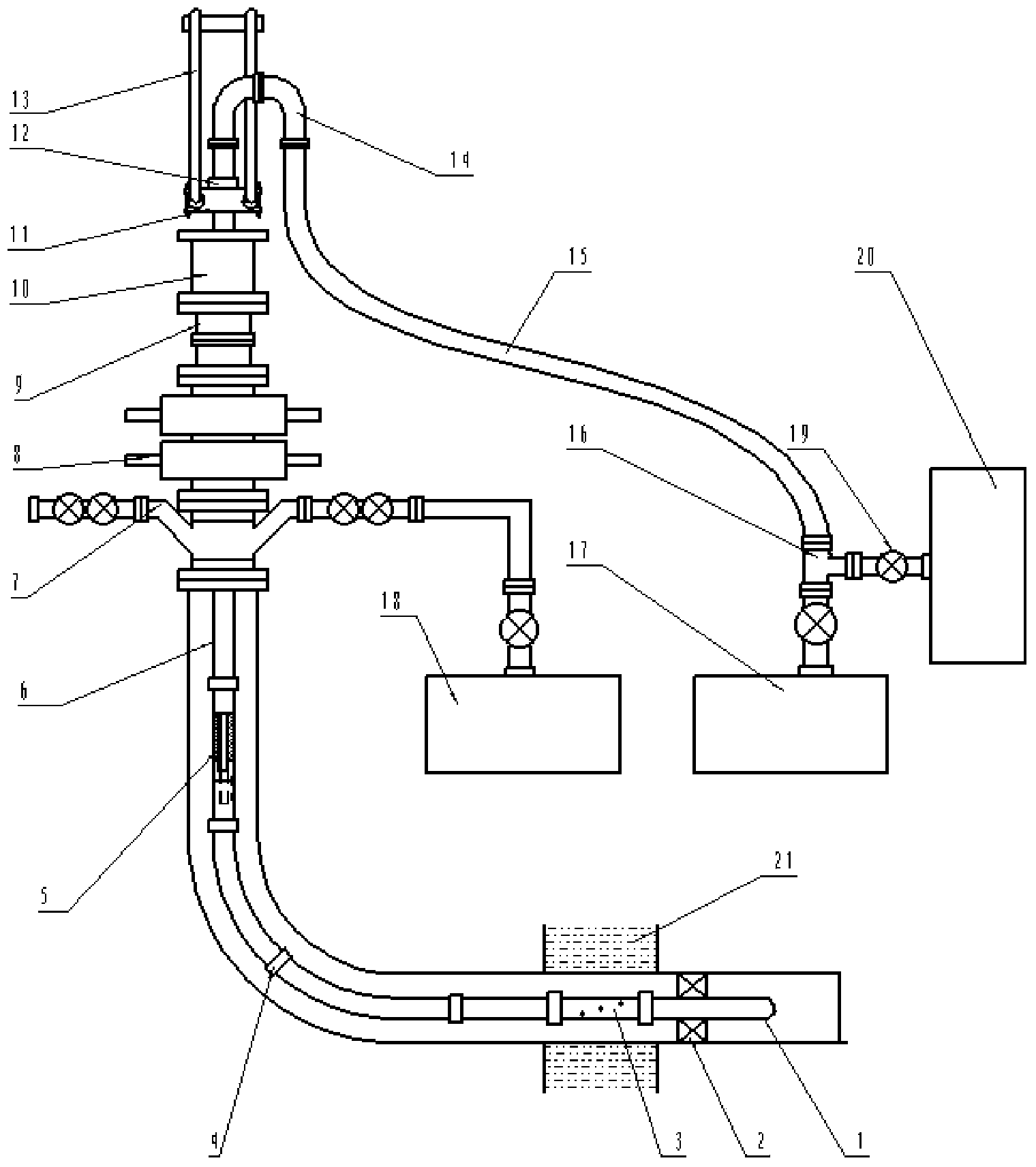

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0013] Such as figure 1 As shown, the pressure-dragging layered fracturing device of the present invention includes surface equipment and downhole tool strings, and the downhole tool strings include a cone plug 1, a packer 2, a hydraulic spray gun 3, a coupling tubing 4, Abrasion-resistant check valve 5, uncoupling tubing 6; surface equipment includes wellhead cross 7 corresponding to the pressure level during fracturing, on which double ram blowout preventer 8 is installed, and on double sluice The plate blowout preventer 8 is connected with the blowout preventer 9, and the blowout preventer 9 is connected with the anti-top pneumatic slip 10, and the upper end of the oil pipe without joint hoop 6 passes through the wellhead four-way 7, the double ram blowout preventer 8, the preventer The spray box 9 and the anti-top pneumatic slip 10 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com