Electric tracer agent injector with bottom face where isotope carrier can be filled

An injector and isotope technology, applied in the fields of instruments, scientific instruments, nuclear radiation exploration, etc., can solve the problems of expanding pollution, inconvenient carrying, labor and time-consuming, etc., to ensure the safety of the environment and personnel, avoid trouble, and maintain the gate. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

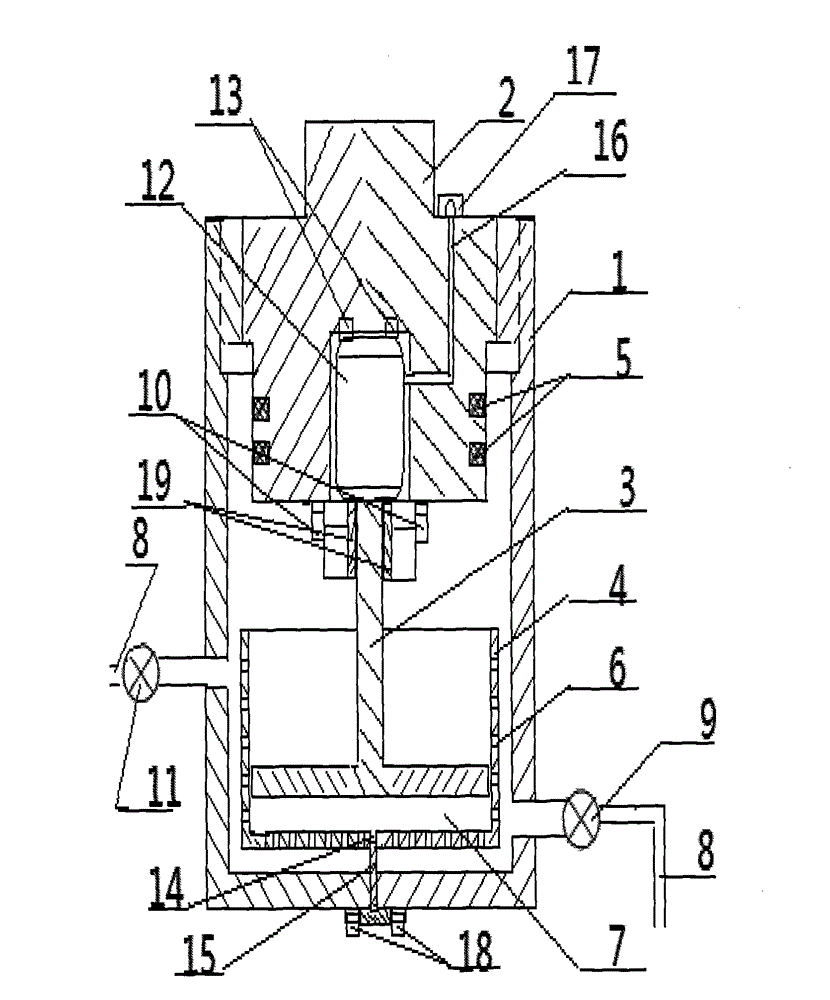

[0014] As shown in the accompanying drawings: an electric tracer injector capable of injecting isotope carriers into the bottom surface is mainly composed of an injector box, which is characterized in that: the injector box consists of a stainless steel cavity 1, a Closely combined sealing plug 2, extrusion rod 3, screen 4 and micro reduction motor 12; on the sealing plug 2, there is a rubber sealing ring 5, and the micro reduction motor 12 is connected with the extrusion rod 3 as a whole, located in the extrusion In the sealing plug 2 above the rod 3, the miniature reduction motor 12 is fixed on the sealing plug 2 by the top wire 13, and the joint between the extrusion rod and the motor is provided with a shaft sleeve 19, and the top wire 10 is used to fix the sealing plug 2 and the shaft sleeve 19; The net 4 is set at the bottom of the stainless steel cavity 1, the lower part of the extruding rod 3 is located in the screen 4, and the isotope chamber 7 is formed between the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com