Feedback compensation type hydraulic unloading valve

A feedback compensation and unloading valve technology, which is applied in the field of hydraulic unloading valves, can solve problems such as system damage, load impact, and rapid internal pressure loss, so as to improve efficiency, reduce load unloading opening force, and avoid failure. The effect of pressing too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

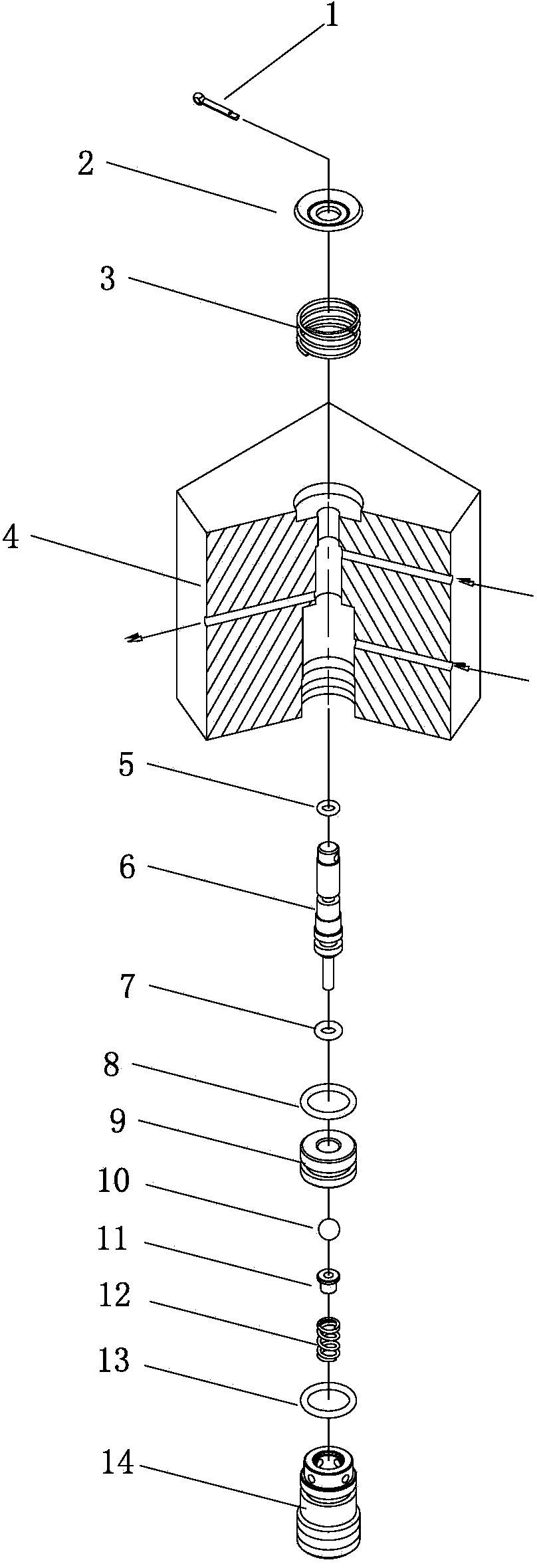

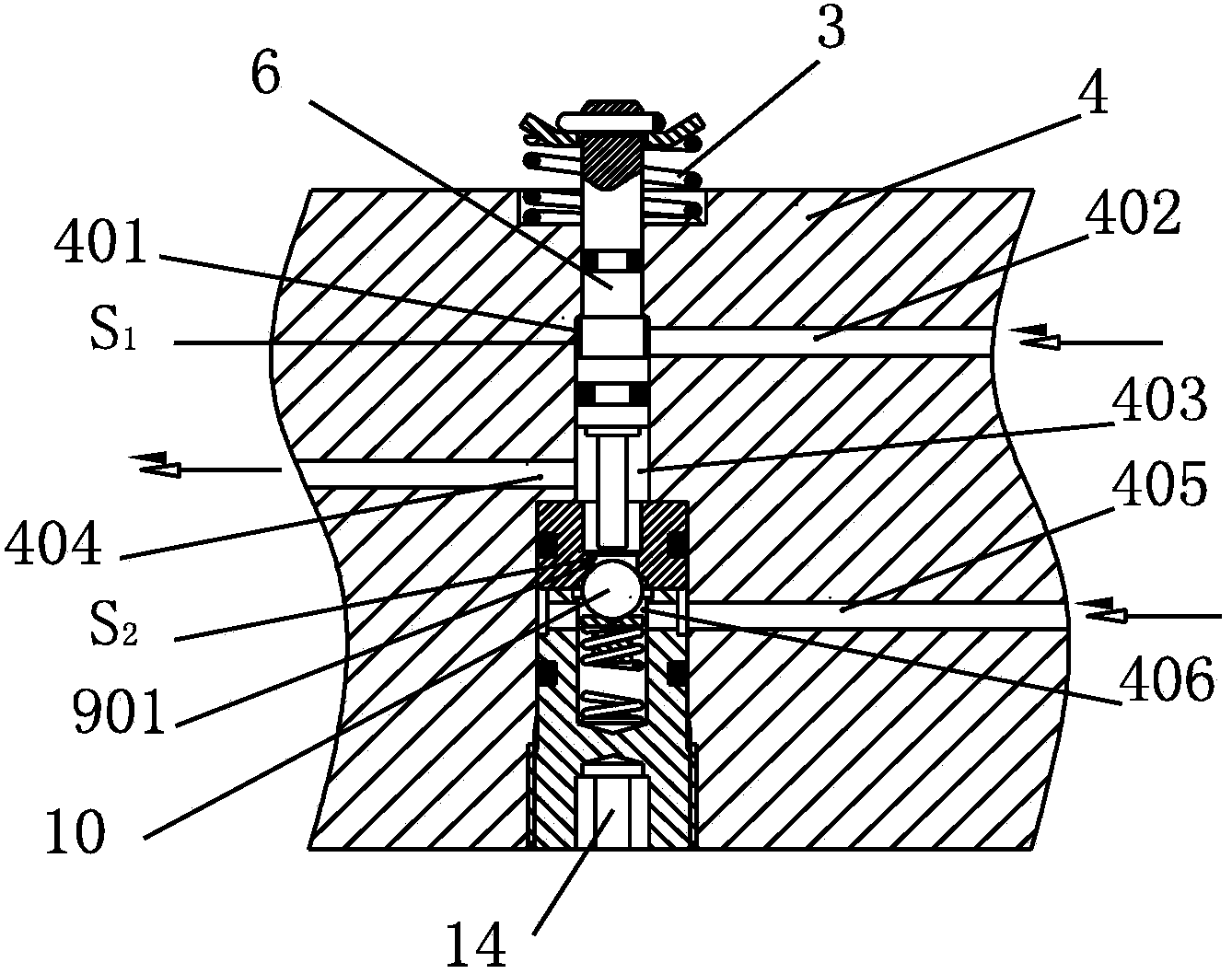

[0022] see figure 1 and figure 2 , a feedback-compensated hydraulic unloading valve, including an oil circuit board 4, an unloading valve core 6 and a plug 14; the oil circuit board 4 cooperates with the unloading valve core 6 to form a first closed cavity 401, which cuts off Area is S 1 , the first closed cavity 401 communicates with the first oil passage 402 of the oil circuit plate 4; a valve seat 9 with a through hole 901 in the center is provided below the unloading valve core 6, and the cross-sectional area of the through hole 901 is S 2 The lower end surface of the valve seat 9 is provided with a valve ball 10 that can close the through hole; the valve seat 9, the valve ball 10, the unloading valve core 6 and the inner wall of the oil circuit plate 5 form a second closed cavity 403, and the second closed cavity 403 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com