Carbon fiber prepreg interlayer slip force measurement device and method

A carbon fiber prepreg, measuring device technology, applied in measuring devices, force/torque/work measuring instruments, mechanical devices, etc., can solve the problems of difficult control of heating temperature and large force error, and achieve easy operation and simple structure. , flexible and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

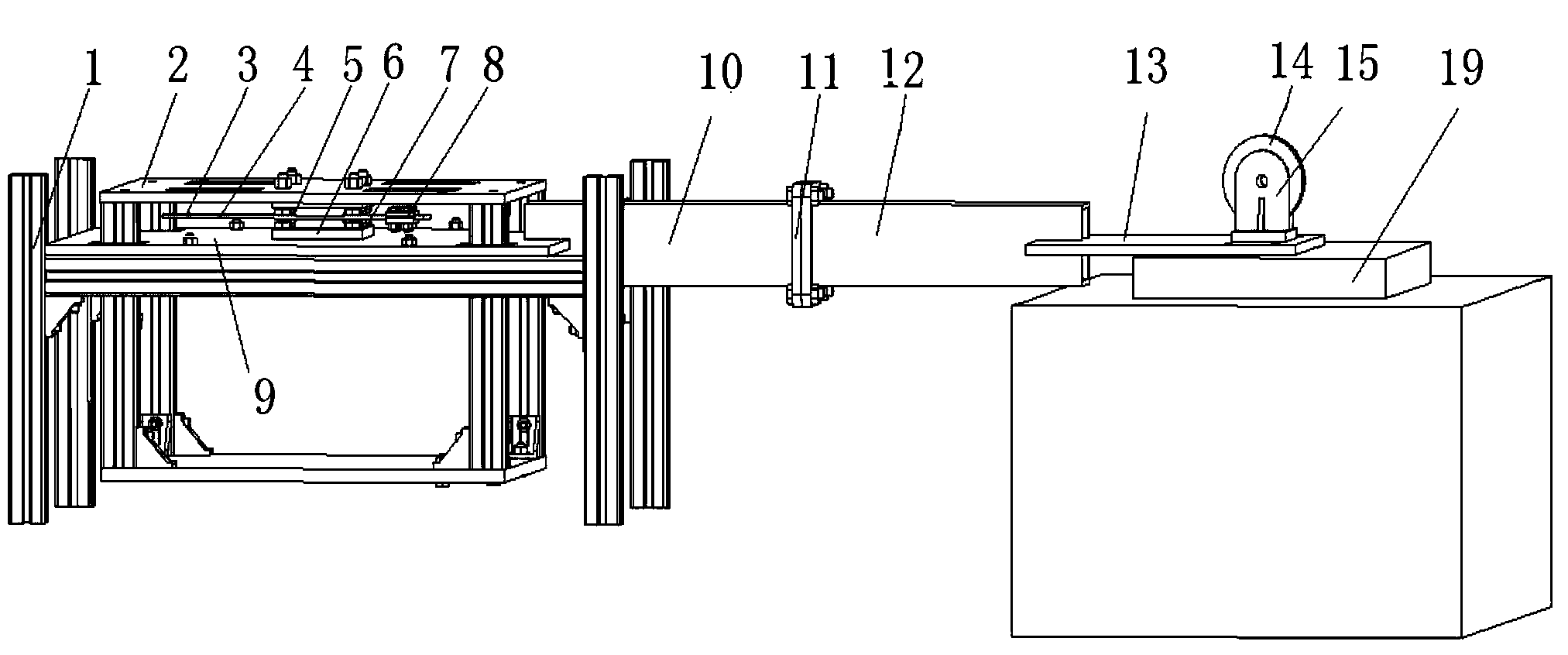

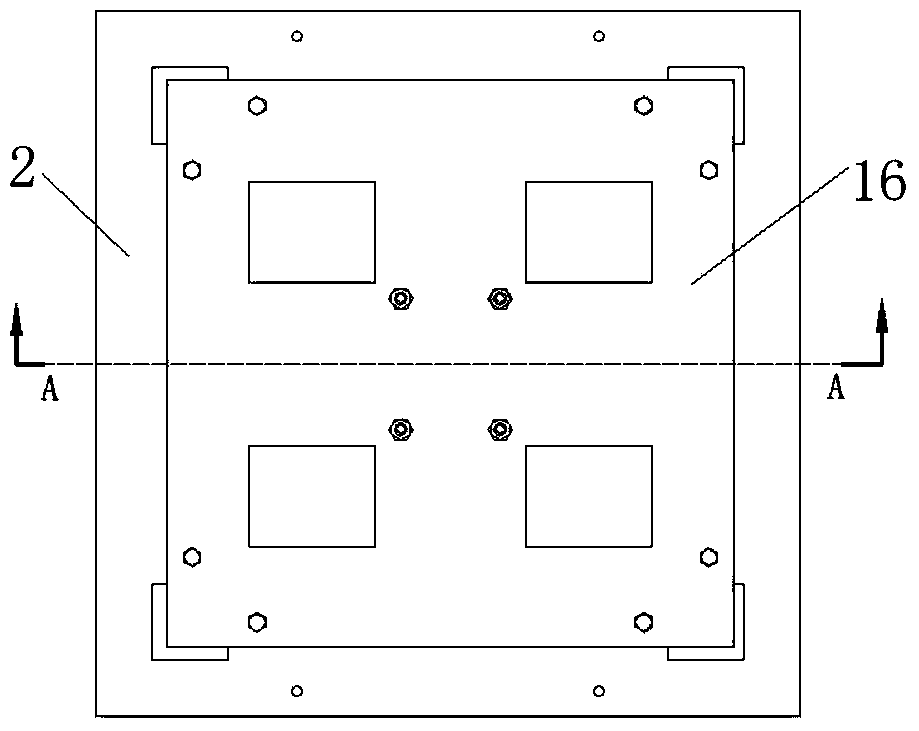

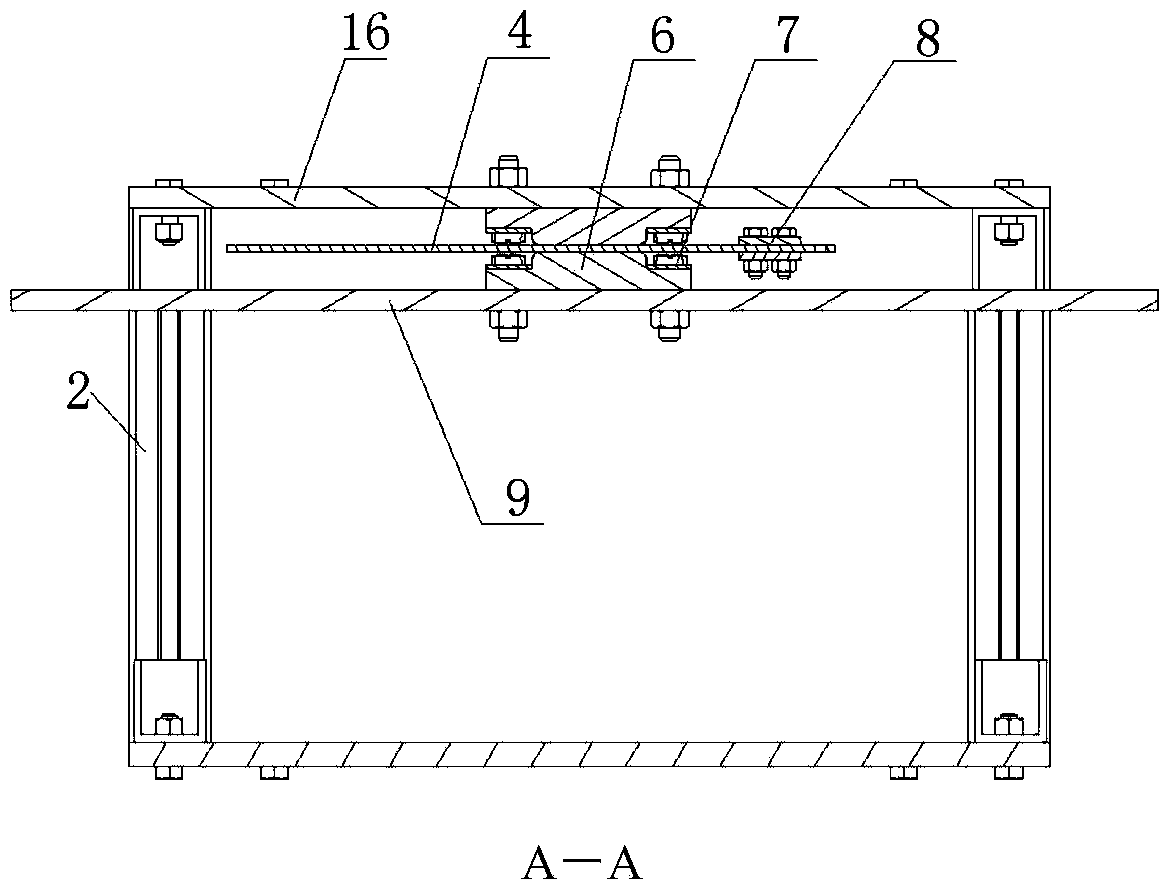

[0046] This embodiment is a device for measuring the sliding force between layers of carbon fiber prepreg, including a bracket 1, a load frame 2, a carbon fiber prepreg fixing seat and a carbon fiber prepreg sliding mechanism. Wherein, the bracket 1 is the carrier of this embodiment, and the bearing frame 2 is installed on the bracket panel 9 of the bracket. The carbon fiber prepreg fixing seat is located in the bearing frame 2, and the carbon fiber prepreg fixing seat includes two bases 6 with the same structure, one of which is an upper base and the other is a lower base. The upper base is fixed on the lower surface of the top plate 16 of the bearing frame, the lower base is fixed on the upper surface of the bracket panel 9, and the carbon fiber prepreg fixing surfaces of the two bases 6 correspond to each other and have a spacing, which is equal to the backing plate The sum of the thickness of the carbon fiber prepreg and the thickness of the four layers of carbon fiber pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com