Reprogrammable device, method for manufacturing semiconductor device

A manufacturing method and semiconductor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

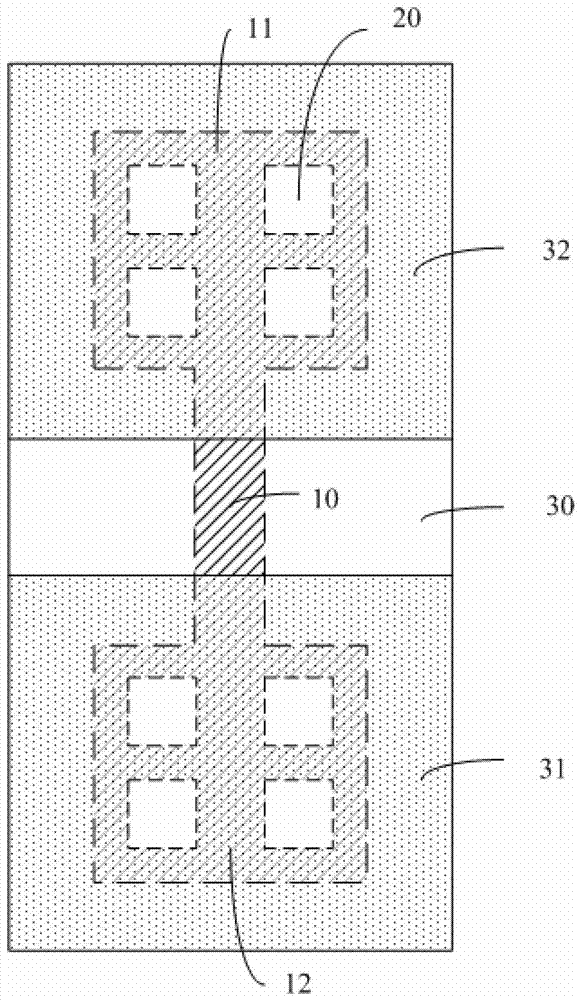

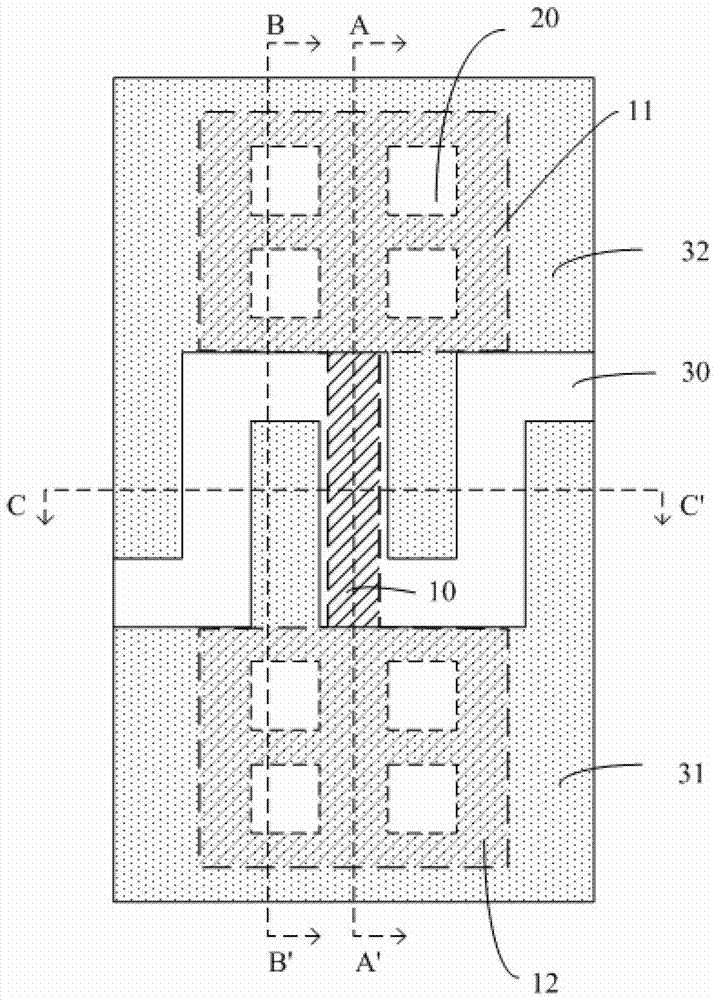

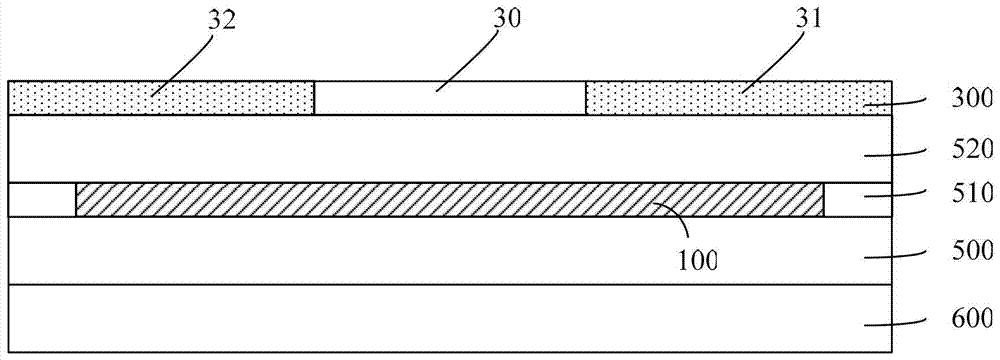

[0042] The technical solution of the present invention provides a multi-time programmable device, which is mainly composed of fuses and antifuses connected in parallel. Specifically, the fuse includes an anode and a cathode, and a fuse part located between the anode and the cathode, and when a large current passes through the fuse part, the fuse part will be blown. The antifuse includes two electrodes, and a dielectric layer between the two electrodes. When a voltage is applied to the two poles of the antifuse, positive and negative charges will be accumulated on the two electrodes respectively, when the positive and negative charges on the two poles accumulate to the breakdown charge Q bd , so that when the voltage between the two poles is large enough, there is a current path at a certain point in the dielectric layer, so that the current increases instantaneously and the resistance drops, that is, the dielectric layer is broken down, so that the antifuse is guided Pass. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com