Dispensing module, applicator head and nozzle holder for dispensing a fluid, in particular hot-melt adhesive

A technology of hot-melt adhesive and dispensing module, which is applied in the field of hot-melt adhesive and coating head, and can solve the problem of difficulty in adjusting the precise length of the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

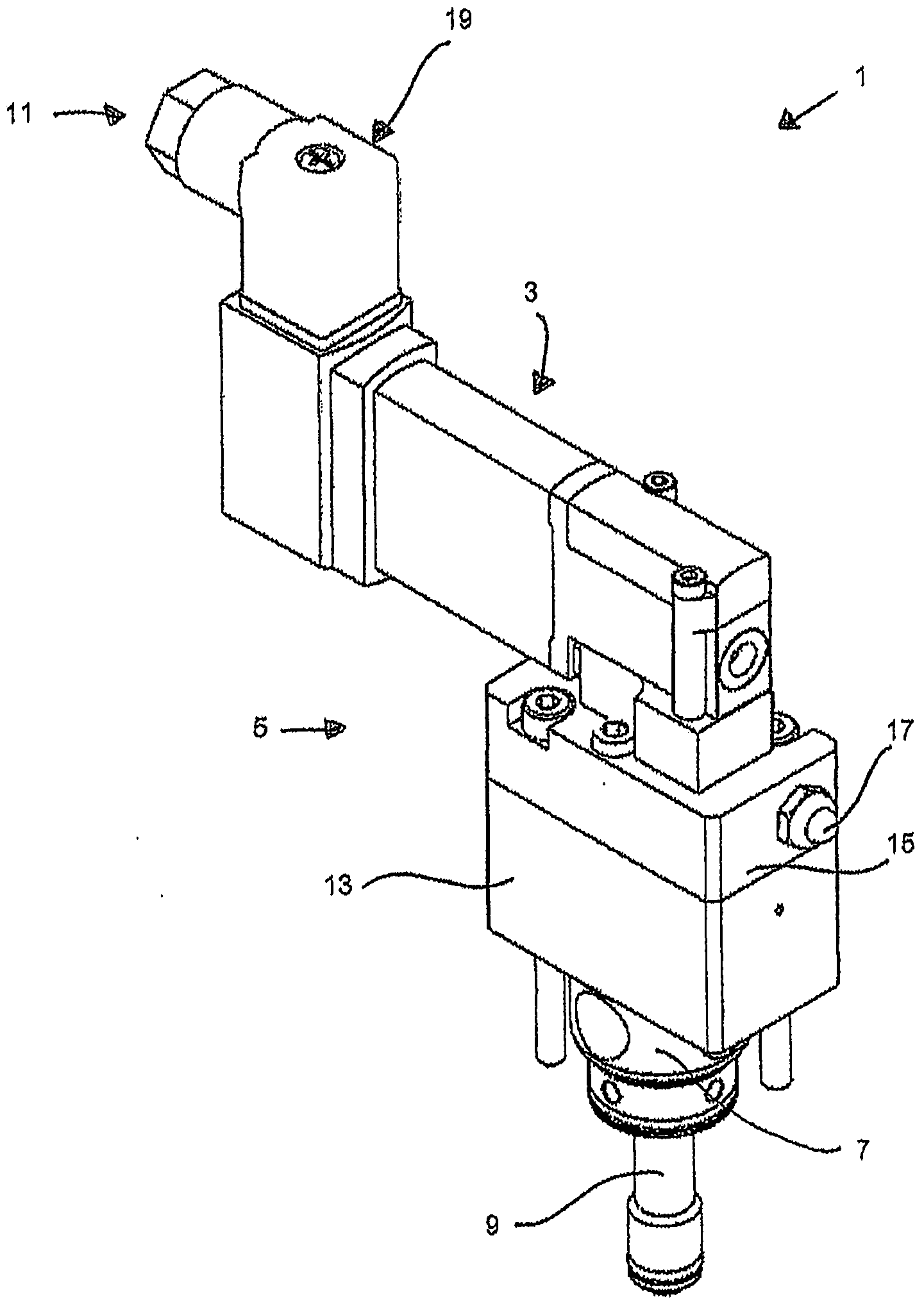

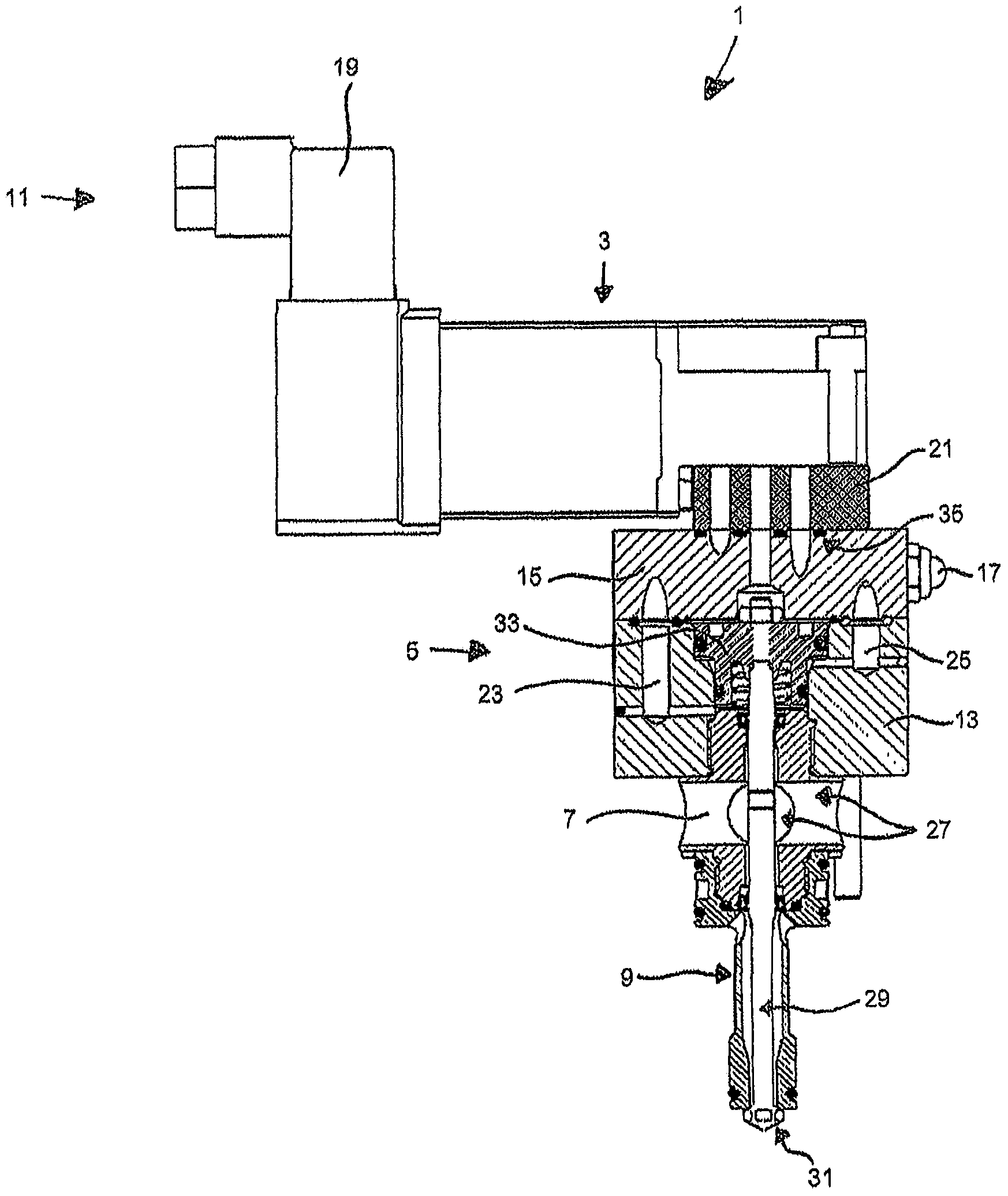

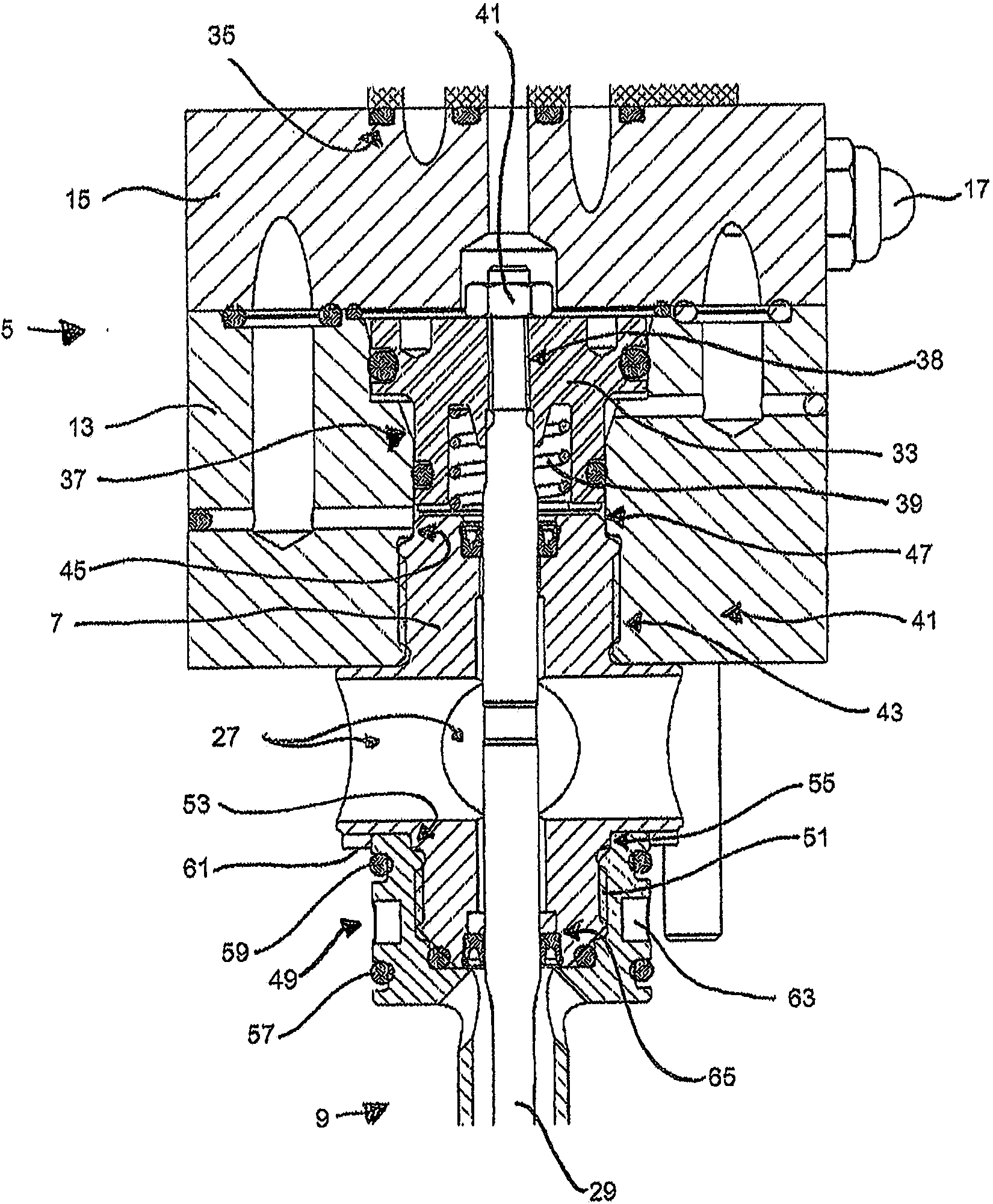

[0029] figure 1 The distribution module 1 is shown. The distribution module 1 has an actuator 3, which in this example is in the form of a solenoid valve. The actuator 3 is connected to the module housing 5 of the distribution module 1. The distribution module 1 also has an adapter 7 connected to the module housing 5. The nozzle holder 9 is connected to the adapter 7 of the dispensing module 1.

[0030] A connector seat 19 is provided on the actuator 3, and the connector seat 19 has an electrical connector 11 for supplying electric energy to control the actuator 3. In this embodiment, the module housing 5 has a two-piece structure. In this embodiment, the two-piece modular housing has a cylindrical housing 13 and a housing cover 15. The muffler 17 is provided in the housing cover 15. The muffler is screwed into the housing cover 15 of the module housing.

[0031] figure 2 show figure 1 Side view of the distribution module 1. Regarding repeated reference signs, please pay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com