A cigarette that does not produce second-hand smoke

A technology for second-hand smoke and cigarettes, applied in the field of cigarettes, can solve the problems of large differences in the actual feelings of electronic cigarettes, negative effects on people's health, and inability to truly simulate the flavor of cigarettes, so as to control the content of harmful substances, improve utilization, and reduce negative effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a novel cigarette is provided, comprising the steps of:

[0038] S1.2012 Hunan Xiangxi Zhongju San (A) re-cured tobacco leaves, rolled into cylindrical tobacco bundles (length 84mm, diameter 7.8mm);

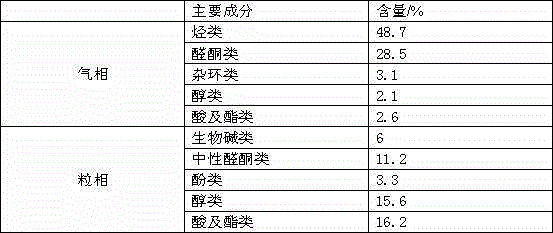

[0039] S2. Use a smoking machine to suck the smoke bundle, control the suction speed to a constant speed (35mL / puffs (2s)) and minimize the smoldering of the smoke bundle, and collect the particulate matter of the mainstream smoke through the Cambridge filter, Condensate and recover the gas phase of the mainstream smoke at -60°C; collect the particulate matter;

[0040] S3. Mix the collected gas phase condensate and the particulate phase, and apply the mixture as a coating solution on the paper base, with a coating amount of 5%; after drying, cut into shreds and roll to obtain the cigarette, shredded The thickness refers to the existing cigarette production technology routine. The paper base of this example adopts the papermaking method to reconsti...

Embodiment 2

[0048] A method for preparing a novel cigarette is provided, comprising the steps of:

[0049] S1.2012 Guizhou Zhongjusan (C1) re-cured tobacco leaves, shredded and rolled into cylindrical tobacco bundles (80mm in length, 7.7mm in diameter);

[0050] S2. Use a smoking machine to suck the cigarette bundles, and suck multiple cigarette bundles at the same time, control the suction speed to a uniform speed (45mL / puffs (2s)) and minimize the smoldering of the smoke bundles, pass through the Cambridge filter The chip collects the particulate matter of the mainstream smoke, and condenses and recovers the gas phase of the mainstream smoke at -60°C; collects the particulate matter;

[0051] S3. Mix the collected gaseous condensate and the granular phase, and apply the mixture as a coating solution on the paper base with a coating amount of 10%; after drying, cut into shreds and roll to obtain the new cigarette. The paper base of this example adopts the papermaking method to reconstit...

Embodiment 3

[0062] A method for preparing a novel cigarette is provided, comprising the steps of:

[0063] S1.2012 Yunnan Zhongjusan (A) re-cured tobacco leaves, rolled into tobacco bundles (length 90mm, diameter 8.2mm);

[0064] S2. Use a smoking machine to suck the smoke bundle, control the suction speed to a constant speed (40mL / puffs (2s)) and minimize the smoldering of the smoke bundle, and collect the particulate matter of the mainstream smoke through the Cambridge filter, And condense and recover the gas phase of the mainstream smoke at -80°C;

[0065] S3. Mix the collected gaseous condensate and particulate matter, and apply the mixture as a coating solution on the paper base with a coating amount of 15%; after drying, cut into shreds and roll to obtain the new cigarette. The paper base of this example adopts the papermaking method to reconstitute the tobacco leaf paper base.

[0066] Contrast 1: The same kind of tobacco leaves were treated in the same way as in this example to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com