Ceramic-based pyramid lattice structure type composite material preparation mold

A technology of base pyramid and lattice structure, applied in the field of ceramic base pyramid lattice composite material preparation, can solve the problems of non-straight demoulding of core rods, difficult one-time molding, uneven panel collapse, etc., and achieves convenient preparation and stable performance , path-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

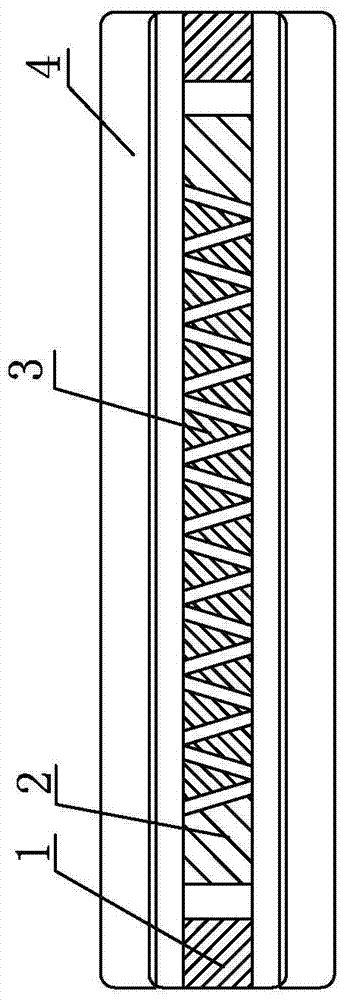

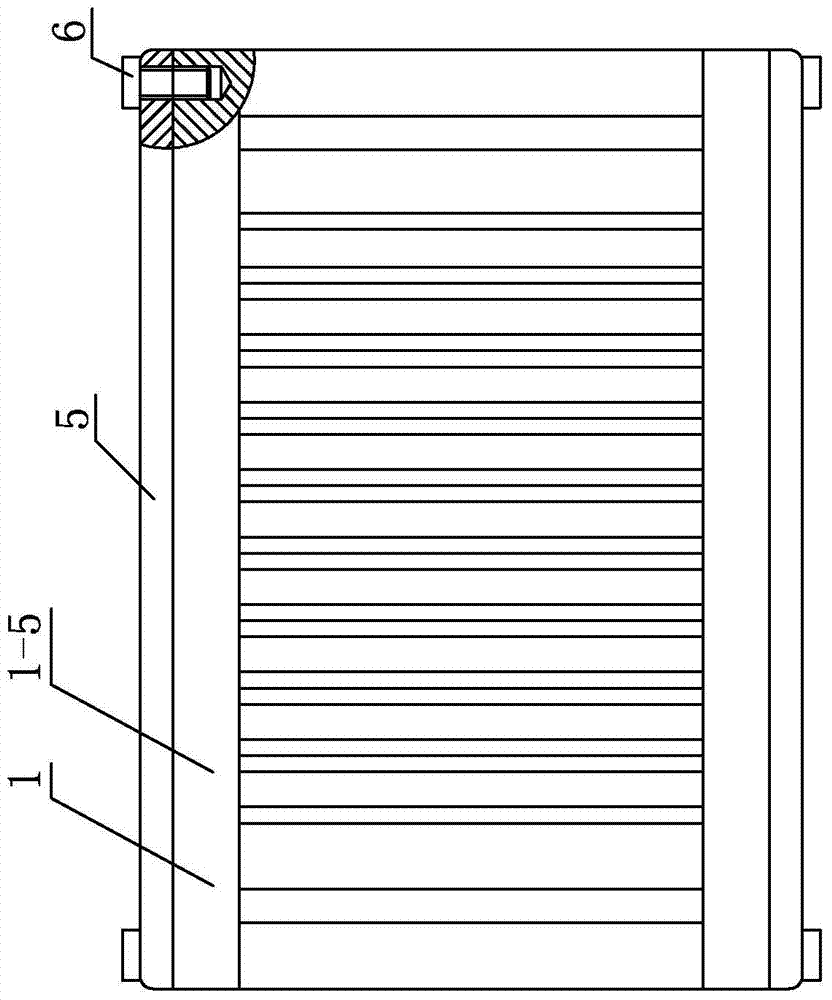

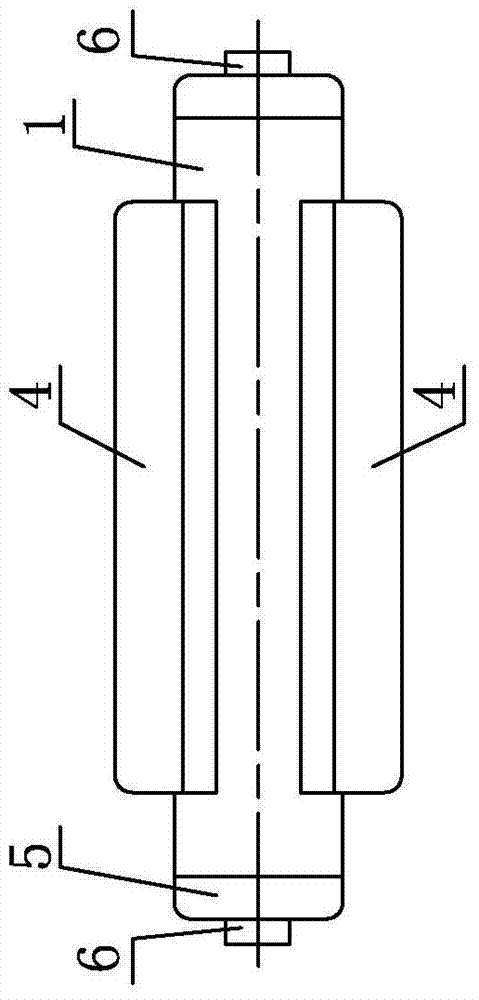

[0009] Specific implementation mode 1: Combination Figure 1-Figure 16 It is explained that a ceramic-based pyramid lattice structure composite material preparation mold of this embodiment includes a hollow frame 1, two trapezoidal inserts 2, two pressing plates 4, two side plates 5 and a plurality of triangular inserts 3;

[0010] The cross section of the hollow frame 1 is H-shaped, and the two ends of the hollow frame 1 are respectively processed with a first through hole 1-1 with a trapezoidal cross section along the width direction of the horizontal arm 1-6, located at the two first through holes 1 The hollow frame 1 between -1 is machined along the width direction of the horizontal arm 1-6 with a plurality of second through holes 1-2 with a triangular cross section, and the first through holes 1-1 are inserted with the first through holes 1-1 The matching trapezoidal insert 2, the second through hole 1-2 is inserted with a triangular insert 3 that matches the second through ...

Example Embodiment

[0011] Specific implementation manner two: combination Figure 4 with Figure 16 It is explained that the upper and lower sides of the first through hole 1-1 in this embodiment are both parallel to the upper surface of the upright arm 1-5 of the hollow frame 1, and the two first through holes 1-1 are hollowed out respectively. The center line of the frame 1 is symmetrically arranged on the symmetry axis. This setting is convenient for forming C f / SiC ceramic-based pyramid lattice structure material to meet the design requirements. Others are the same as the first embodiment.

Example Embodiment

[0012] Specific implementation mode three: combination Figure 4 with Figure 16 It is explained that the cross section of the second through hole 1-2 in this embodiment is an isosceles triangle, the adjacent two sides of two adjacent second through holes 1-2 are parallel, and the distance between the two parallel adjacent sides is equal. This setting ensures that the C f / SiC ceramic-based pyramid lattice structure composite material has mechanical properties, uniform structure and stable performance. Others are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com