Fluorescent powder color wheel automatic coating device

A fluorescent pink wheel and automatic coating technology, applied in the direction of the spray device, can solve the problems of long time consumption, low coating efficiency, poor product performance, etc., and achieve the effect of fast fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

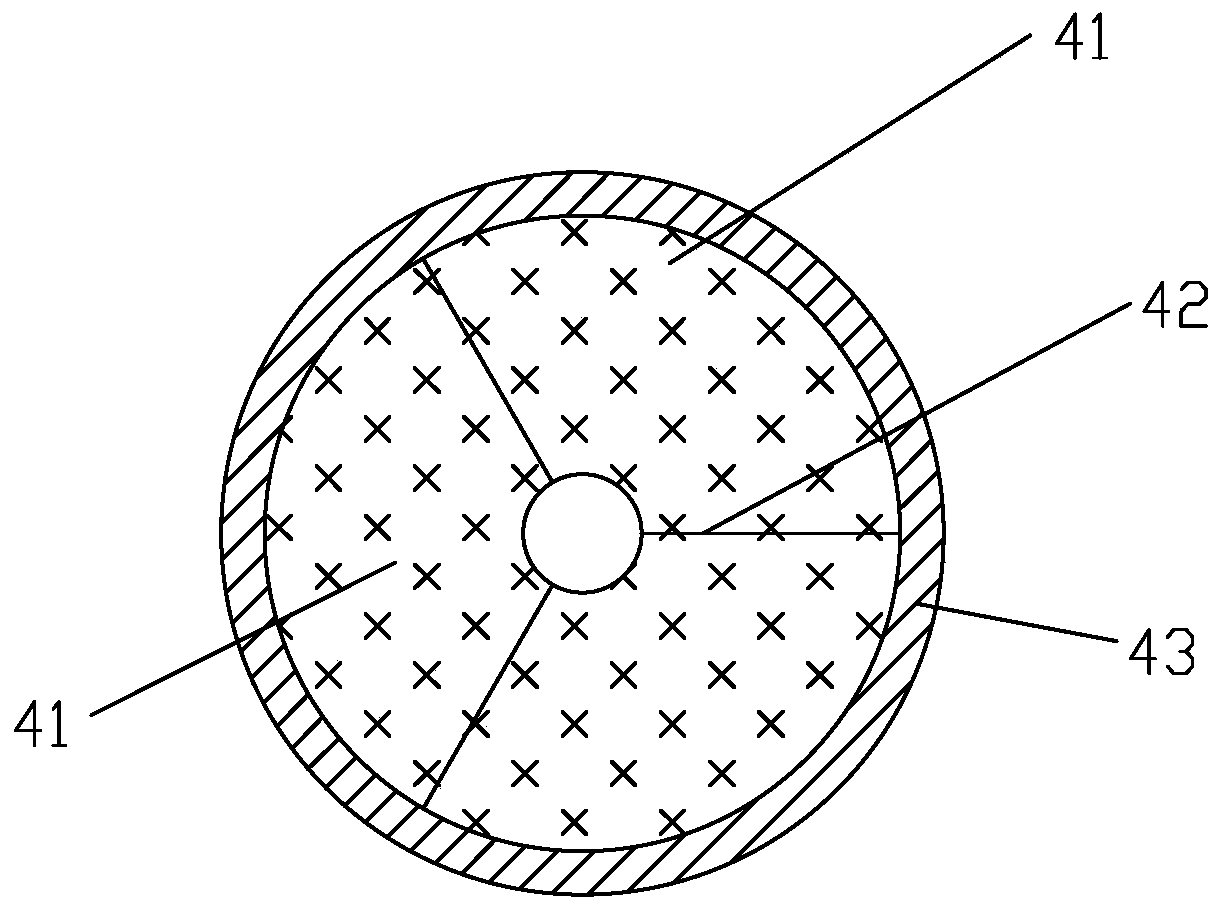

[0031] The color wheel substrate in this embodiment is as figure 2 As shown, it is disc-shaped, with a hole in the center. Before the coating process, a protective film 41 and a color label 42 are pasted, leaving the uncovered parts such as figure 2 The area 43 to be coated is shown. In this embodiment, three colors of coating materials are designed, and the color wheel substrate to which it belongs is divided into three fan-shaped areas with the center of the circle as the center, and the color labels are set at the boundaries of each area.

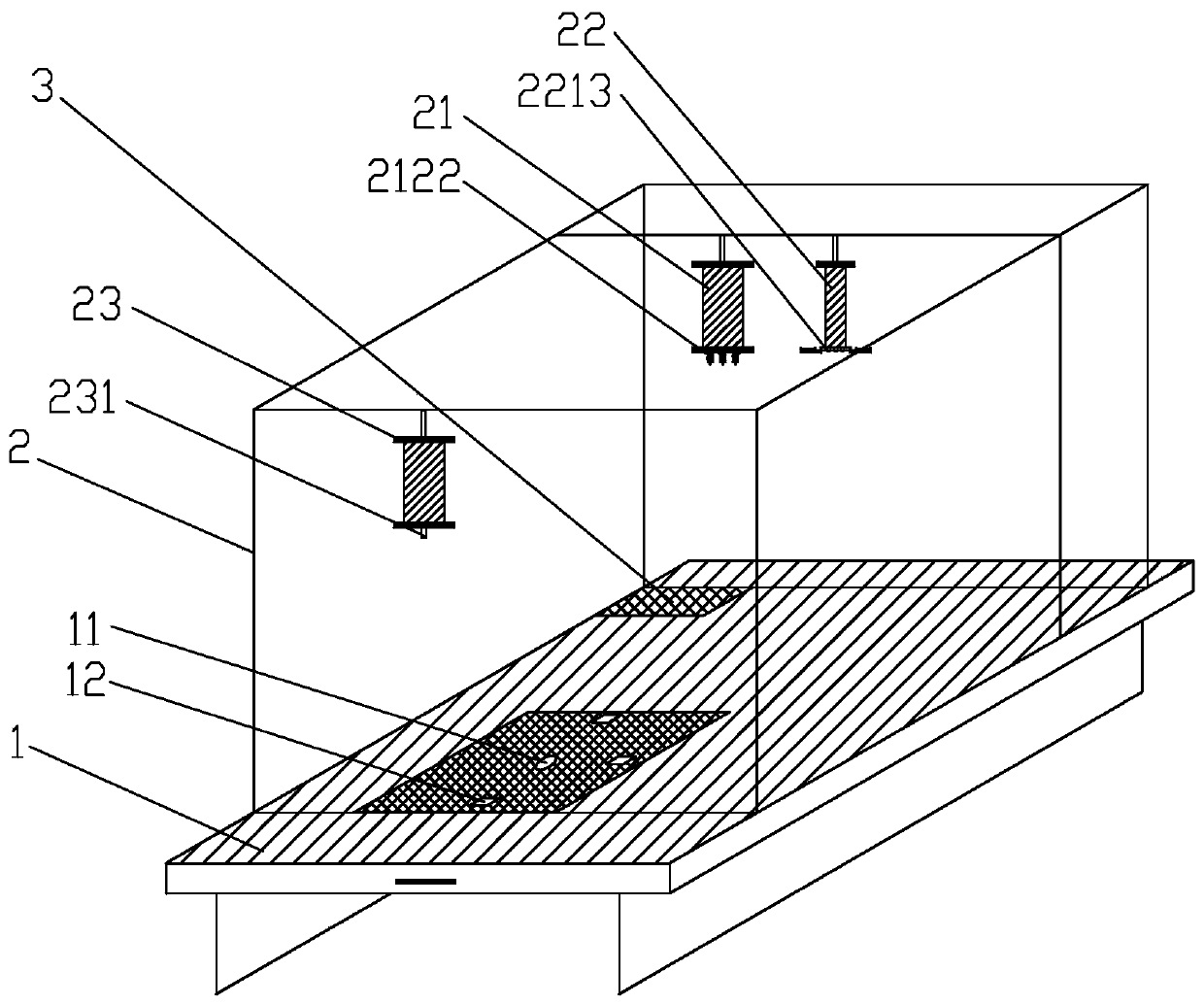

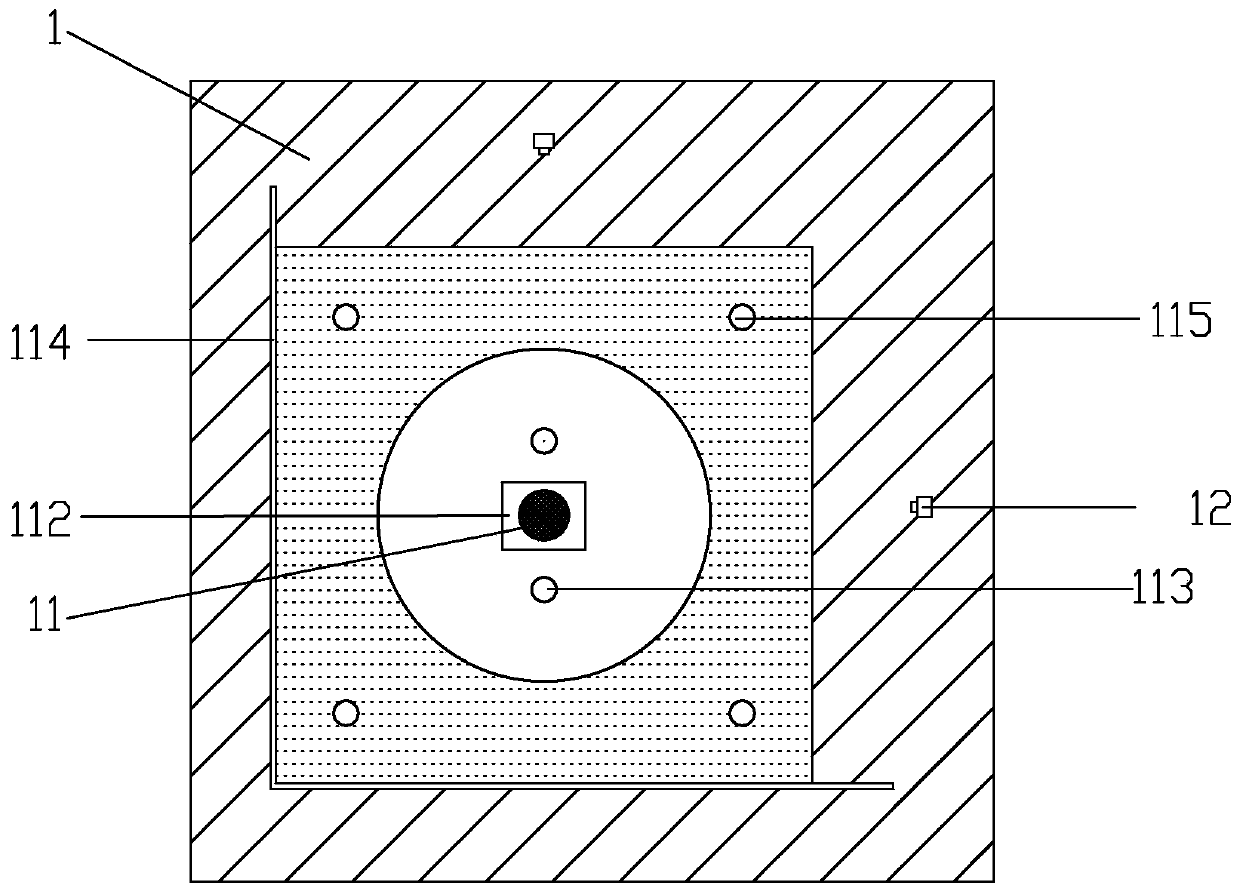

[0032] Such as figure 1 , 2 As shown in and 3, a fluorescent pink wheel automatic coating equipment includes an organic base 1 and a frame 2, and is characterized in that: the base 1 is provided with a device capable of clamping the color wheel substrate and driving the color wheel substrate to rotate. The clamping device 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com