Inkjet coding machine nozzle support frame structure

A coding machine and supporting frame technology, applied in printing and other directions, can solve problems such as inconvenient position adjustment and unfavorable coding efficiency, and achieve the effects of convenient operation, increased adaptability, and beneficial coding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

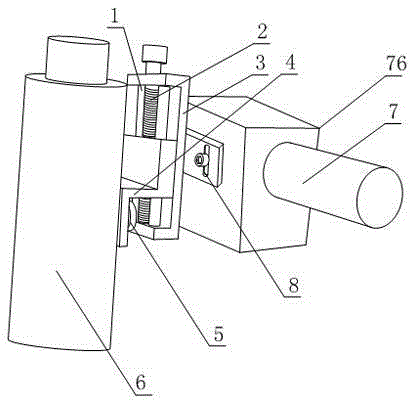

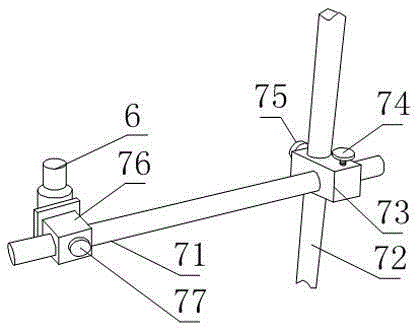

[0020] Such as figure 1 and figure 2 , the nozzle support structure of the inkjet coding machine provided by the present invention includes a mounting frame 7 and an inkjet head connection block 4 connected to the mounting frame 7, and also includes a height adjustment part 3; the height adjustment part 3 is provided with The height fine adjustment bolt 2 and the guide rod 1, the two ends of the guide rod 1 are fixedly connected to the height adjustment part 3, the height adjustment part 3 is also provided with a bolt hole, the height fine adjustment bolt 2 is partially located in the bolt hole, and The height fine adjustment bolt 2 can rotate around the bolt hole and the positional relationship between the height fine adjustment bolt 2 relative to the height adjustment part 3 does not change, the height fine adjustment bolt 2 and the guide rod 1 are parallel to each other, the inkjet head connecting block 4 is connected The bolts 2 are threaded, and the inkjet head connecti...

Embodiment 2

[0023] This embodiment is further limited on the basis of embodiment 1: as figure 1 and figure 2 , in order to make the height of the height adjustment part 3 relative to the installation frame 7 linearly adjustable within a small range, the height adjustment part 3 is also provided with a bar-shaped hole 8, and the height adjustment part 3 and the installation frame 7 are arranged on a bar-shaped The connection bolts of hole 8 are fixedly connected.

Embodiment 3

[0025] This embodiment is further limited on the basis of embodiment 1: as figure 1 and figure 2 , the inkjet head connection block 4 includes two flat plates parallel to each other and a connecting plate connecting the two flat plates, any one of which is provided with fine-tuning threaded holes and guide rod grooves, and the other plate is provided with a plurality of thick Adjust the bolt hole or a bar-shaped hole, and be provided with height coarse-adjusting bolt 5 in any coarse-adjusting bolt hole or bar-shaped hole. The inkjet head connection block 4 of the above structural form is simple in structure, which is conducive to reducing the weight and manufacturing cost of the inkjet head connection block 4. At the same time, the above structural form is convenient to reserve enough space for adjusting the height of the coarse adjustment bolt 5; The height coarse adjustment bolt 5 is used to connect the inkjet head 6, and adopts the structural form of multiple coarse adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com