Mechanism for double-truck butt joint and garbage transfer of garbage trucks

A technology of garbage truck and translation mechanism, which is applied in garbage conveying, garbage collection, garbage storage and other directions, can solve the problem of environmental sanitation, does not have translation mechanism, does not consider bulk garbage transfer, garbage waste water docking transfer, anti-odor overflow and anti-bulk problems such as garbage scattering, to achieve the effect of reducing operating costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

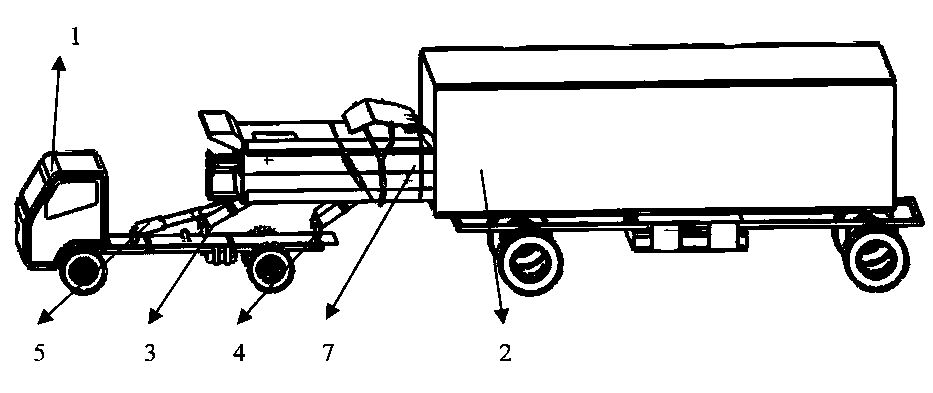

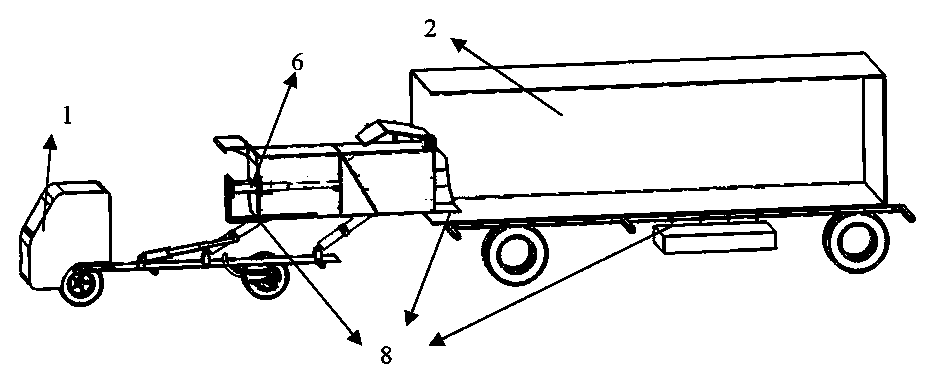

[0017] like figure 1 and figure 2 As shown in the figure, the mechanism for the double-vehicle docking and garbage transfer of garbage trucks of the present invention includes a carriage lifting and translation mechanism for double-vehicle docking, a garbage pushing mechanism 6 in the process of garbage transfer, a garbage waste water pumping mechanism 8 and The docking sealing mechanism 7 of the tail box of the vehicle; wherein, the lift and translation mechanism of the carriage for the docking of the two-vehicle is used to lift and translate the carriage of the small and medium-sized garbage collection vehicle 1, so that the tail cabin is connected to the tail of the large garbage transfer vehicle 2. compartment. During the garbage transfer process, the garbage pushing mechanism pushes and compresses the garbage in the compartment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com