Container Flooring Equipment

A container and floor technology, applied in the field of container floor paving equipment, can solve the problems of complex structure, low floor paving efficiency, poor synchronization, etc., and achieve the effect of simplifying equipment structure, fewer equipment parts, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

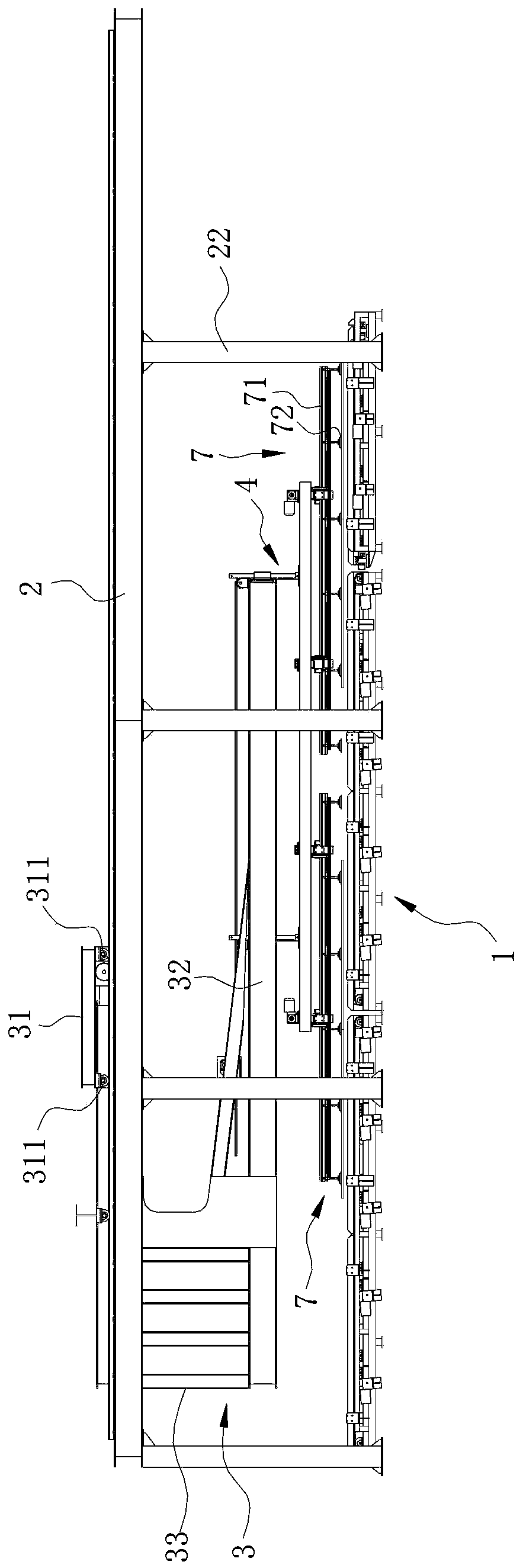

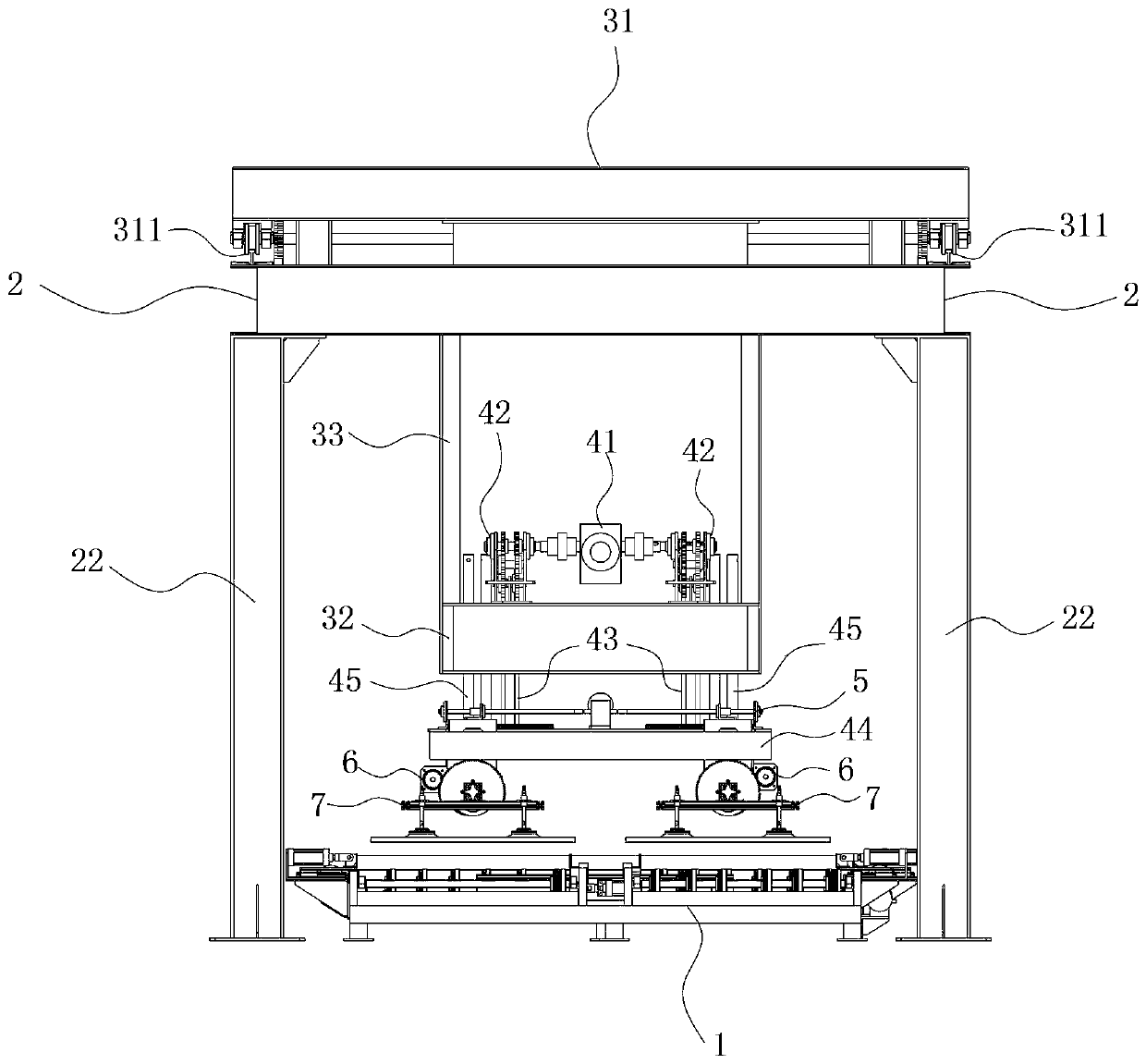

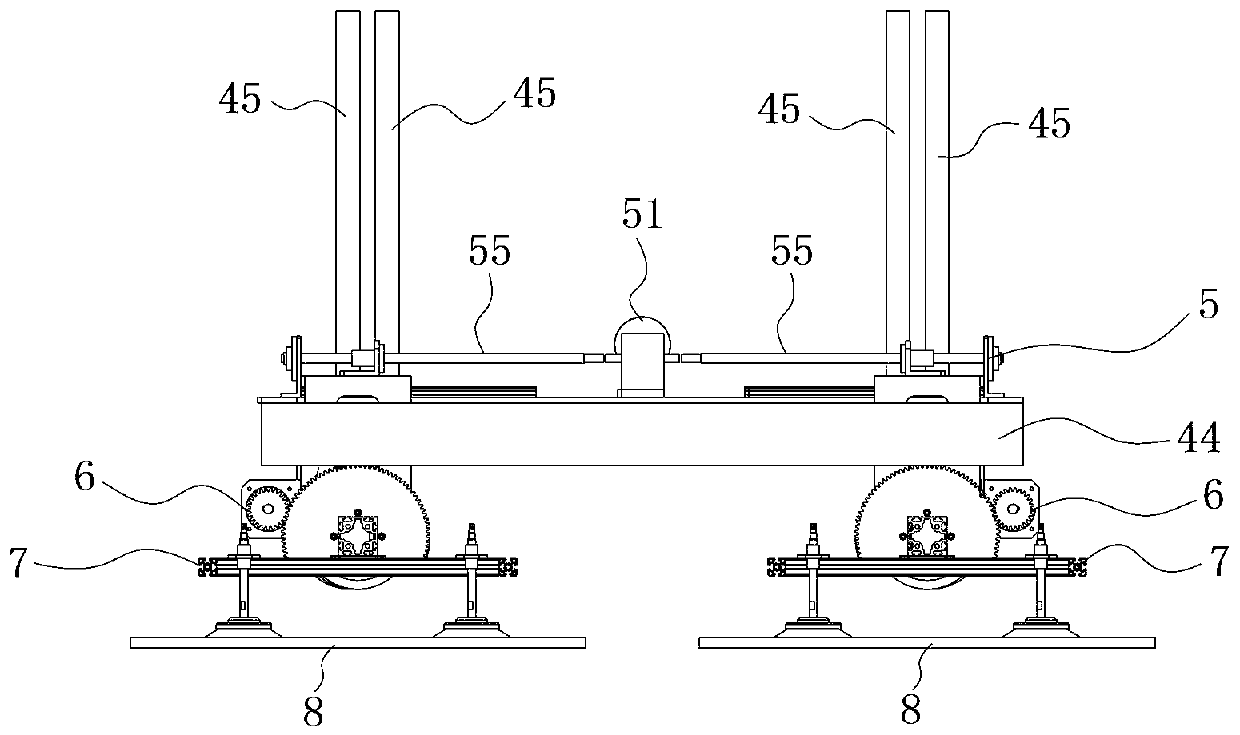

[0039] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0040] The container floor pavement equipment of the present invention is arranged on the outside of the container door end. When describing the orientation, the length direction of the container is taken as the longitudinal direction, the width direction of the container is taken as the transverse direction, and the end close to the container door end is taken as the front end, and the side far away from the container door end is taken as the front end. One end is the backend.

[0041] refer to figure 1 and figure 2 , the container floor pavement equipment of the present invention comprises: the material preparation mechanism 1 that is arranged on the ground, the track 2 that is arranged longitudinally, the walking mechanism 3 that can move along the track 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com