Rotary wheel type spring press-conveying device

A runner type and runner technology, which is applied to the device field of bagging machines, can solve problems such as restricting the production speed of bagged springs, and achieve the effect of high-speed production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

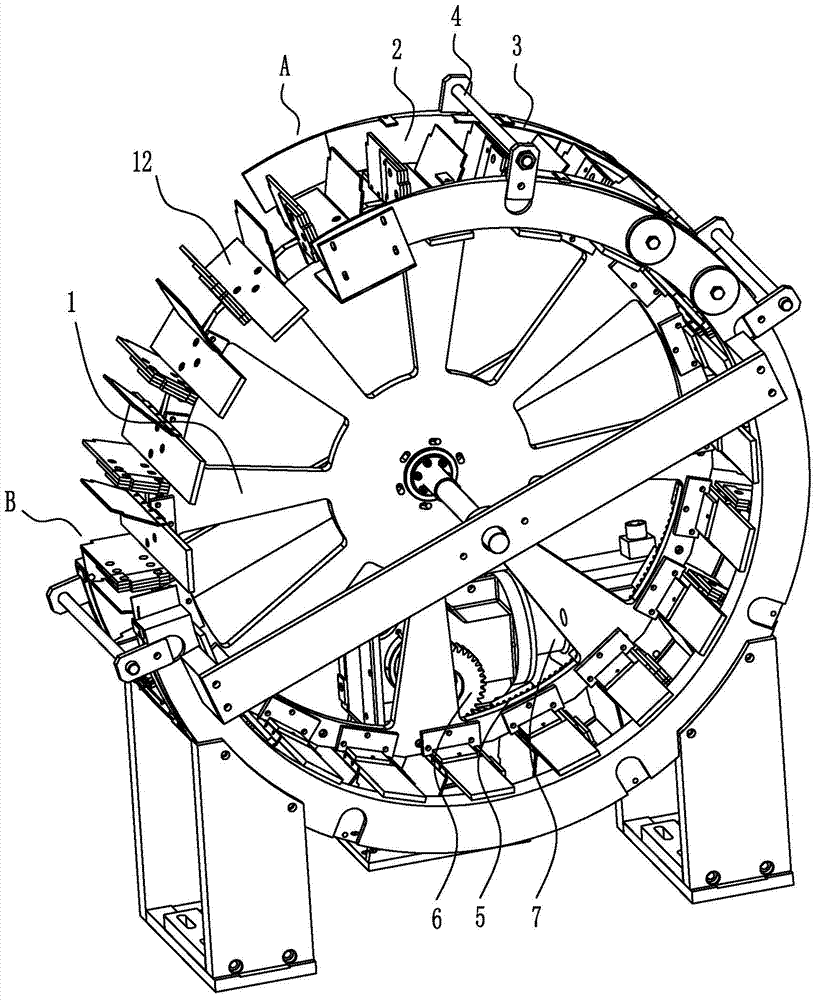

[0009] Such as figure 1 As shown, a runner type spring pressure feeding device includes a runner 1, and the runner 1 is provided with clamping positions 12 for clamping springs at intervals along its circumference, and both sides of the runner clamping positions 12 are provided with fixed The side block 2, the outer circumference of the runner 1 is provided with a fixed outer block 3, the side block 2 and the outer block 3 extend from the spring inlet position A to the spring outlet position B along the direction of rotation of the runner 1, and the side blocks 2 on both sides The distance between them gradually narrows along the direction of rotation of the runner. The side block 2 and the outer block 3 form an arc-shaped chute that can accommodate the sliding of the spring, and the runner 1 rotates in the arc-shaped chute, and with the rotation of the runner 1, the spring that falls on the runner clamping position 12 is locked. Sliding in the ring chute. Since the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com