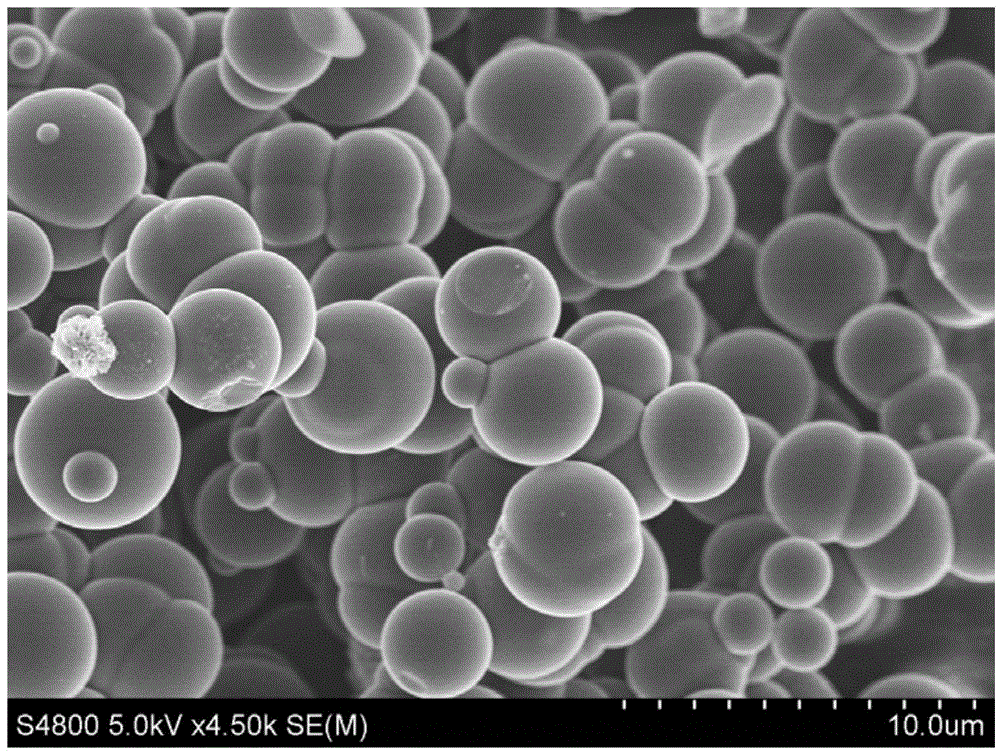

A kind of preparation method of melamine glyoxal microspheres with parent-child morphology

A technology of melamine glyoxal and sub-mother morphology is applied in the field of preparation of melamine glyoxal microspheres, and can solve the problems of complex processing technology, poor thermal stability of resin microspheres, low specific surface area and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific embodiment one: this embodiment is a kind of preparation method of the melamine glyoxal microsphere with mother-in-law appearance, specifically is finished according to the following steps: 1, glyoxal and melamine are added in deionized water, in oil Stir at a bath temperature of 60°C until evenly mixed, then raise the temperature to 180°C to 220°C within 1h to 1.5h, condense and reflux at a temperature of 180°C to 220°C for 20 to 26h, stop heating and naturally cool to room temperature to obtain melamine B Dialdehyde reaction solution; 2. Ultrasonic disperse the melamine glyoxal reaction solution obtained in step 1 until uniform, then wash it with deionized water for 2 to 3 times, wash it with ethanol for 1 to 2 times, and then wash it at 5000~8000r / min Centrifuge down, remove the supernatant, take the lower precipitate and place it in an oven at 60-90° C. to dry for 8-12 hours to obtain melamine glyoxal microspheres with the shape of mother and child.

[0013...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the glyoxal described in step 1 is an aqueous solution of glyoxal with a mass fraction of 40%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of glyoxal to deionized water in step 1 is (10-20):30. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com