Porous zirconium phosphate-based monatomic catalyst for removing formaldehyde, and preparation method thereof

A zirconium phosphate-based catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of re-release of formaldehyde, difficulty in controlling the release of by-product ozone, and low activity of negative ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

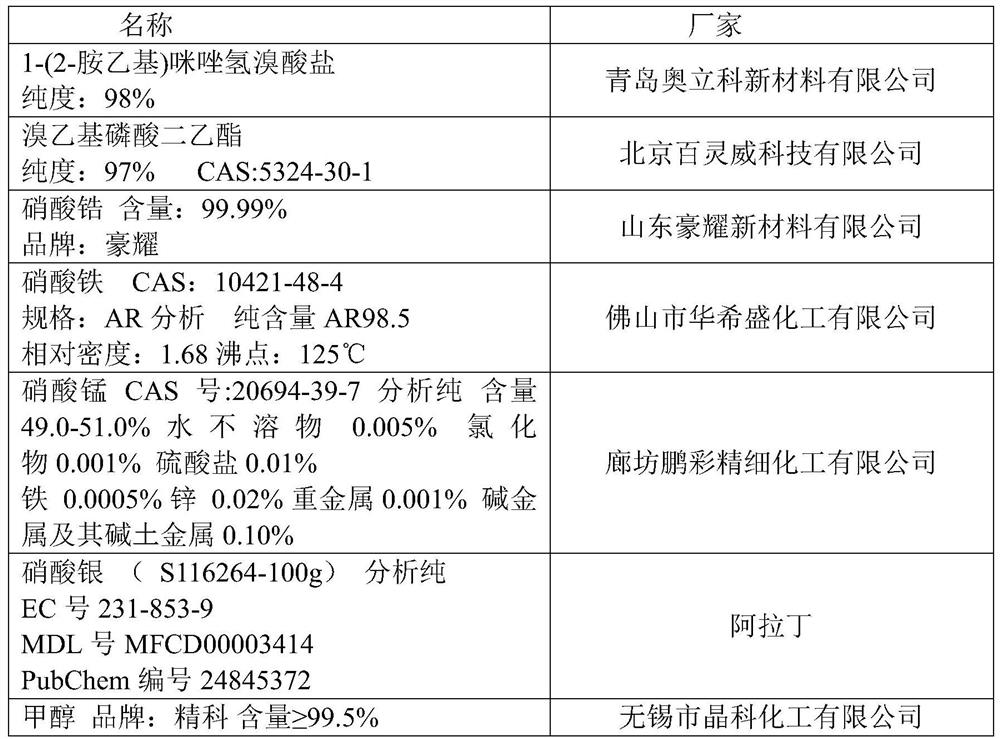

[0037] Preparation of 1-(2-aminoethyl)-3-(2-diethoxyphosphate)ethylimidazolium bromide liquid: 1-(2-aminoethyl)imidazole hydrobromide with a molar ratio of 1:3 Salt and bromoethyl diethyl phosphate use methanol as solvent, reflux and stir at 90°C for 36h; after the reaction, cool to room temperature, and remove the solvent by rotary evaporation to obtain a viscous liquid, dissolve the obtained liquid in water, add equimolar Sodium hydroxide, stirring at room temperature for 1h, rotary evaporation to remove water, and filtering off solid sodium bromide, vacuum drying for 2h, to obtain ionic liquid 1-(2-aminoethyl)-3-(2-diethoxyphosphate ) ethyl imidazolium bromide.

Embodiment 1

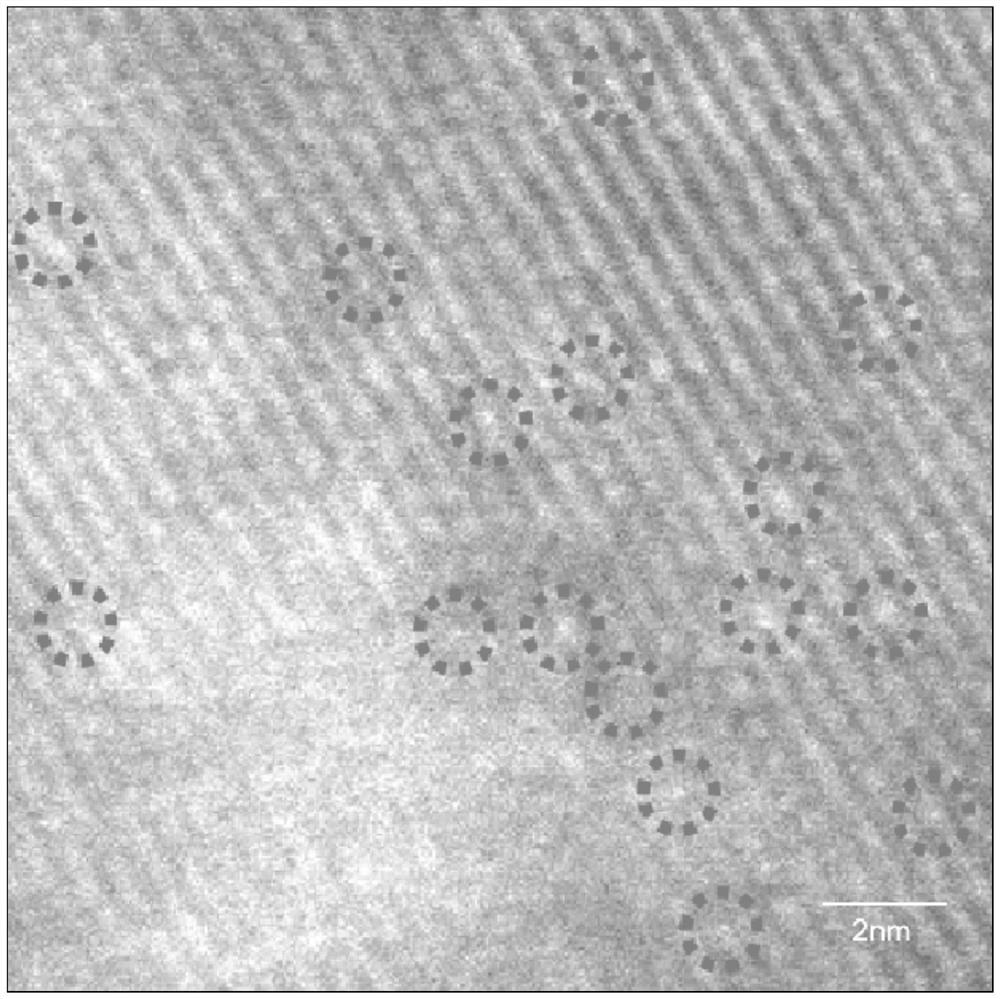

[0040]A porous zirconium phosphate-based single-atom catalyst for formaldehyde removal disclosed in this application is prepared from the following raw materials: porous nano-zirconium phosphate and transition metal; the transition metal is Fe, and the transition metal is in-situ in the form of a single atom packaged on a carrier.

[0041] A preparation method for a porous zirconium phosphate-based single-atom catalyst for removing formaldehyde, comprising the following steps:

[0042] Step 1, preparation of porous nano-zirconium phosphate precursor: 1-(2-aminoethyl)-3-(2-diethoxyphosphate) ethylimidazolium bromide and zirconium nitrate with a molar ratio of 2:3:2 , water and stirred for 30 minutes, and mixed evenly to obtain mixed solution A;

[0043] Step 2, preparation of transition metal single-atom precursor: Add 40ml of 5% ammonia solution dropwise at a rate of 100μL / sec to 200ml of 200g / L ferric nitrate solution and stir for 3h, then raise the temperature to 60°C withi...

Embodiment 2

[0047] A porous zirconium phosphate-based single-atom catalyst for formaldehyde removal, which is prepared from the following raw materials: porous nano-zirconium phosphate and a transition metal; the transition metal is manganese, and the transition metal is in-situ encapsulated on a carrier in the form of a single atom .

[0048] A preparation method for a porous zirconium phosphate-based single-atom catalyst for removing formaldehyde, comprising the following steps:

[0049] Step 1, preparation of porous nano-zirconium phosphate precursor: 1-(2-aminoethyl)-3-(2-diethoxyphosphate) ethylimidazolium bromide and zirconium nitrate with a molar ratio of 2:3:2 , water and stirred for 30 minutes, and mixed evenly to obtain mixed solution A;

[0050] Step 2, preparation of transition metal monoatomic precursor: Add 20ml of 5% ammonia solution dropwise at a rate of 100μL / sec to 100ml of 100g / L manganese nitrate solution and stir for 3h, then raise the temperature to 60°C within 30mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com