Hydrotreating method of heavy crude oil

A technology for hydrotreating and feedstock oil, applied in hydrotreating process, treating hydrocarbon oil, chemical instruments and methods, etc., can solve the problems of poor stability, rising and shortening of operation cycle in hydrotreating process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

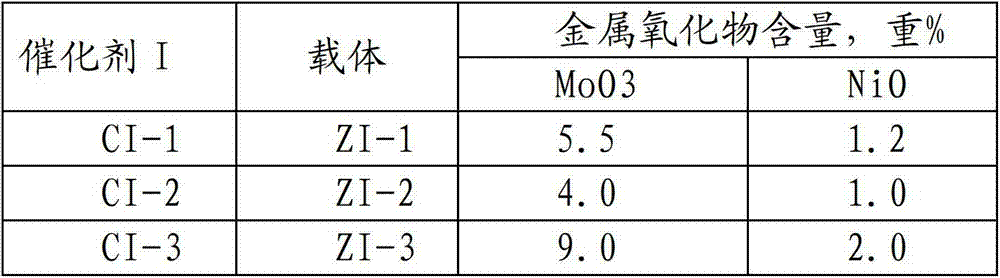

Embodiment 1

[0114] The aforementioned feedstock oil was hydrotreated by using the combination of CI-1, CII-1 and CIII-1 catalysts.

[0115] The loading volume ratios and operating conditions of the three catalyst reactors in the catalyst combination are listed in Table 7. After running for 3000 hours, the samples were analyzed, and the properties of the products are listed in Table 7.

Embodiment 2

[0117] The aforementioned feedstock oil is hydrotreated by using a combination of CI-2, CII-2 and CIII-2 catalysts.

[0118] The loading volume ratios and operating conditions of the three catalyst reactors in the catalyst combination are listed in Table 7. After running for 3000 hours, the samples were analyzed, and the properties of the products are listed in Table 7.

Embodiment 3

[0120] A combination of CI-3, CII-3 and CIII-3 catalysts is used to carry out hydrotreating of the aforementioned feedstock oil.

[0121] The loading volume ratios and operating conditions of the three catalyst reactors in the catalyst combination are listed in Table 7. After running for 3000 hours, the samples were analyzed, and the properties of the products are listed in Table 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com