A Composite Flame Retardant Organic Detergent for Live Insulation Equipment

A technology of compound flame retardant and stain remover, which is applied in the directions of organic non-surface-active detergent compositions, detergent compositions, non-surface-active detergent compositions, etc., can solve the problems of narrow application range and poor effect of water washing, To achieve good lubricity, easy and fast operation, good dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A composite flame-retardant organic decontamination agent for live insulation equipment, which consists of the following raw materials in parts by weight: 85-95 parts of organic solvent, 5-15 parts of stabilizer, and the organic solvent is calculated by percentage by weight: refined Oil 20-40%, flame retardant 15-25%, cleaning agent 20-40%, emulsifying penetrating agent 5-10% and dispersant 5-15%.

[0037] The stabilizer is tert-butylhydroquinone or 1,3-dimethylurea; the flame retardant is Chlorowax-52, Chlorowax-40, decabromodiphenyl ether, four Australian bisphenol A, pentabromotoluene or Hexabromocyclododecane; refined oil after desulfurization treatment, the composition is 8-10C saturated alkanes and unsaturated alkanes; the cleaning agent is a non-aqueous cleaning agent, which can be hydrocarbon solvents, alcohol solvents, ether solvents or hydrocarbons Mixed solvent of solvent and alcohol solvent; emulsifying penetrating agent is fatty alcohol polyoxyethylene ethe...

Embodiment 2

[0039] Composite flame retardant organic detergent for live insulation equipment, 92 parts of organic solvent, 8 parts of stabilizer, organic solvent by weight percentage: 30% of refined oil, 20% of flame retardant, 30% of cleaning agent, emulsified Penetrant 8% and dispersant 12%. Refined oil is desulfurized, the composition is 8-10C saturated alkanes and unsaturated alkanes, the emulsifying penetrating agent is fatty alcohol polyoxyethylene ether, the stabilizer is tert-butyl hydroquinone, and the flame retardant is hexabromocyclododecane Alkanes, the cleaning agent is C12-C16 coconut oil alcohol.

[0040] This composite flame retardant organic detergent is tested as follows:

[0041] Test equipment and conditions: 1) Conductivity tester; 2) Power frequency test transformer 1000KV;

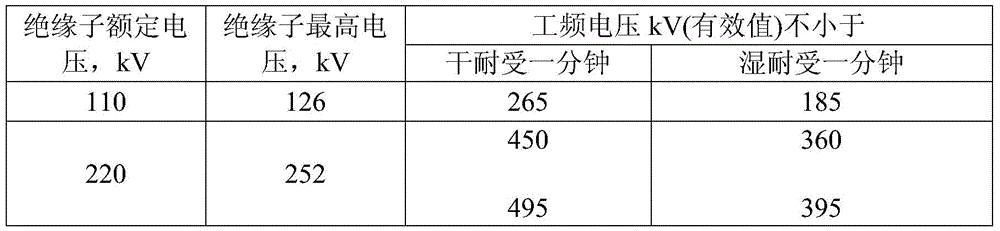

[0042] 3) According to the national standard, the insulator withstand test voltage is as follows:

[0043] Table 1 is the insulator withstand test voltage

[0044]

[0045] 2 Test voltage...

Embodiment 3

[0084] Composite flame retardant organic detergent for live insulation equipment, 90 parts of organic solvent, 10 parts of stabilizer, organic solvent by weight percentage: 32% of refined oil, 25% of flame retardant, 30% of cleaning agent, emulsified Penetrant 6% and dispersant 7%. Others are the same as embodiment 1.

[0085] The composite flame retardant organic detergent is used for the power frequency flashover voltage test on the insulator. The test shows that: during the test, about 75% of the specified flashover voltage is applied first, and then it rises to the flashover voltage at a rate of about 2% of the test voltage per second. The flashover voltage is calculated as the arithmetic mean of 5 consecutively measured flashover values.

[0086] Selected sample: hanging bottle model XP70

[0087] Test transformer: 1000kV

[0088] In order to test the accurate measurement of the voltage step-up process of the transformer, 5 test samples are formed into a string, a tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com