Method for recovering copper, zinc and nickel from heavy metal sludge by using copper smelting waste acid

A technology for smelting heavy metal sludge and copper, applied in the field of recovering copper, nickel metal and zinc, can solve the problems of high impurity content of black copper and crude nickel sulfate, inability to reflect the metal value well, and ineffective utilization of valence metals, etc. Considerable metal recovery value, reducing the risk of environmental pollution, and good overall connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

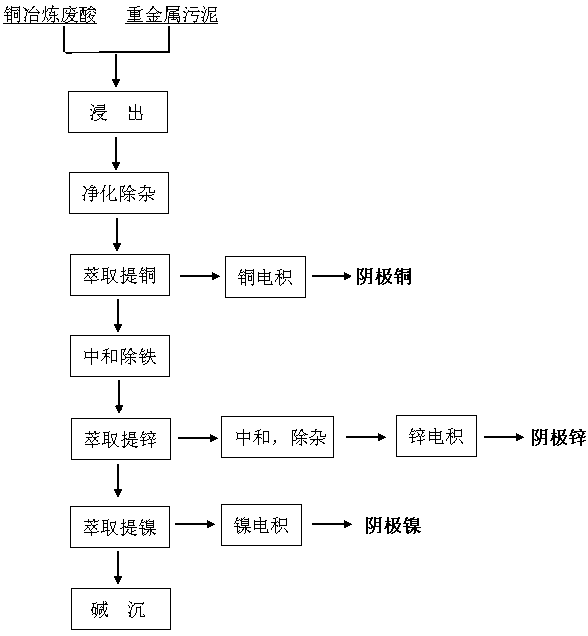

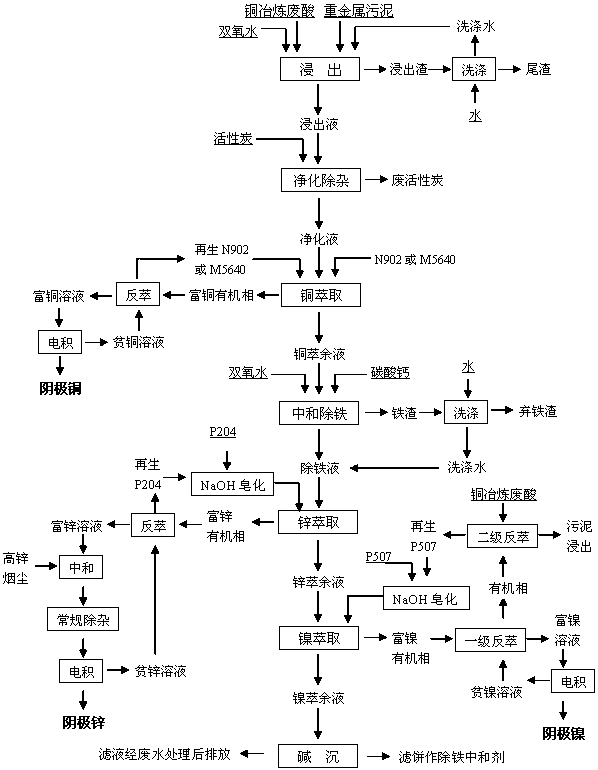

[0038] according to figure 1 The process shown is carried out.

[0039] The contents of main metal ions in copper smelting waste acid and heavy metal sludge in this example are shown in Table 1.

[0040]Main element content in copper smelting waste acid and heavy metal sludge in Table 1 Example 1

[0041] metal element

Cu

Zn

Ni

Fe

Cr

Cd

As

Content in copper smelting waste acid g / L

3.3

0.97

20.52

0.56

0.0019

0.0024

0.35

3 --> Content in heavy metal sludge g / kg

52.3

97.0

8.7

14.2

0.1

0.2

0.2

[0042] Note: The water content of the sludge sample is 80.4%, and the concentration of sulfuric acid in the copper smelting waste acid is 223g / L.

[0043] (1), leaching

[0044] Take the above heavy metal sludge with a water content of 80.4%, use copper smelting waste acid as the leaching agent, control the liquid-solid mass ratio to 10:1 for leaching operation, stir and react...

Embodiment 2

[0059] The contents of main metal ions in copper smelting waste acid and heavy metal sludge in this example are shown in Table 2.

[0060] Contents of major elements in copper smelting waste acid and heavy metal sludge in Table 2 Example 2

[0061] metal element

Cu

Zn

Ni

Fe

Cr

Cd

As

Content in copper smelting waste acid g / L

3.5

0.86

18.43

0.62

0.0017

0.0019

0.33

Content in dry sludge g / kg

48.3

82.0

6.7

12.2

0.1

0.2

0.2

[0062] Note: The water content of the sludge sample is 81.2%, and the concentration of sulfuric acid in the copper smelting waste acid is 219g / L.

[0063] (1), leaching

[0064] Take the above heavy metal sludge with a water content of 81.2%, use copper smelting waste acid as the leaching agent, control the liquid-solid mass ratio to be 12:1 for leaching operation, stir and react at room temperature for 3 hours, and the stirring rate is 100r / min; P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com