Insulation steel silo with parallel structure insulation layer and construction method

A technology of thermal insulation layer and thermal insulation board, applied in thermal insulation, building structure, construction, etc., can solve the problems of easy air leakage, waste of manpower and material resources, long bonding length, etc., to reduce cutting, improve wind resistance, and improve overall rigidity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

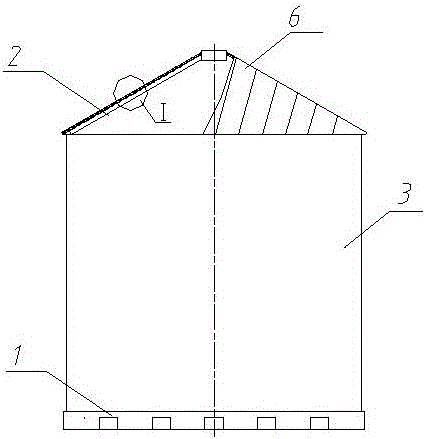

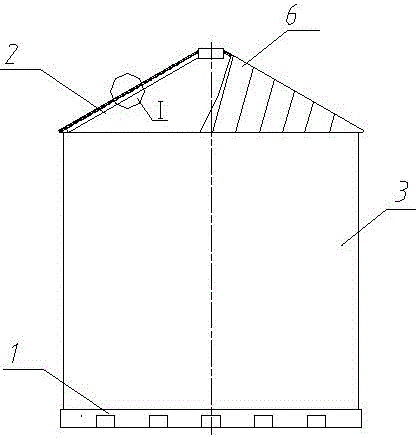

[0029] A thermal insulation steel silo with a parallel structure thermal insulation layer, which consists of: a foundation 1, a silo installed on the foundation, the silo includes a silo roof 2 and a silo body 3, and the silo The outer side of the inner roof 4 of the roof is paved with an insulating layer 5, the outer side of the insulating layer is an outer roof 6, and the insulating layer adopts equal-width insulating boards to continuously pave the structure.

Embodiment 2

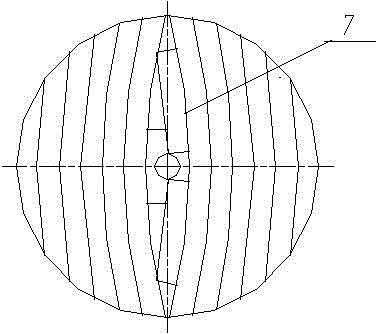

[0031] In the steel silo with a parallel thermal insulation layer described in Example 1, the inner roof 4 also adopts a steel plate of equal width to carry out continuous paving in strips, and the continuous paving structure shows the views figure 2 . In the middle is an olive-shaped central area 7 .

Embodiment 3

[0033] In the heat-insulating steel silo with a parallel thermal insulation layer described in Embodiment 1 or 2, a bite structure is adopted between the panels of the outer roof plate, and the outer roof plate is connected by a tie bar 9 or a tie bar plus a connecting piece 8 It is fixedly connected with the inner top board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com