Water-cooled furnace cover feeding dust removal device and water-cooled furnace cover feeding system

A technology for a water-cooled furnace cover and a feeding system, which is applied in the field of metallurgical technology and flue gas treatment, can solve the problems of smoke and dust spillage, environmental pollution of the workshop, unreasonable structural design of the water-cooled furnace cover charging system, etc., so as to avoid pollution and solve the problem of smoke and dust spillage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

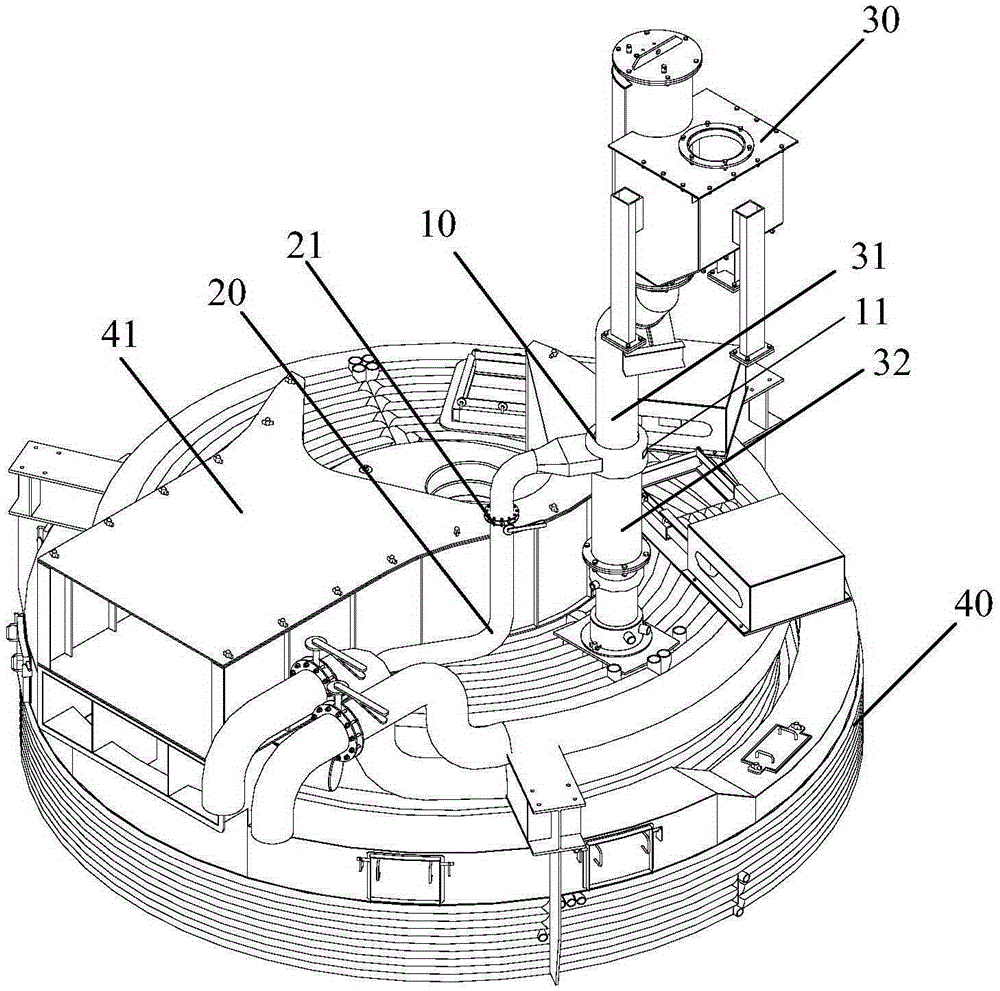

[0023] The water-cooled furnace roof feeding and dedusting device and the water-cooling furnace roof feeding system proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

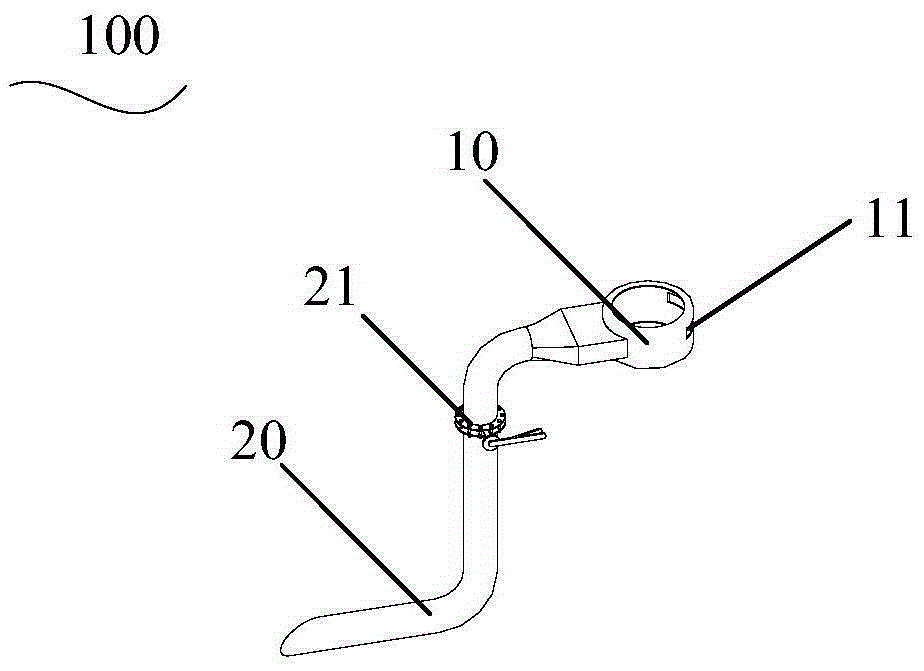

[0024] Please refer to figure 1 , which is a schematic diagram of the structure of the water-cooled furnace roof feeding and dedusting device in an embodiment of the present invention, such as figure 1 As shown, the water-cooled furnace roof feeding and dust removal device 100 includes: a dust removal pipe 20 and a smoke and dust collection ring 10 connected to the dust removal pipe 20 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com