Method for simultaneously realizing sampling, sample addition and stirring of sample needle

A sample needle and stirring motor technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of time-consuming, complex structure, etc., and achieve the effects of convenient use, compact structure and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

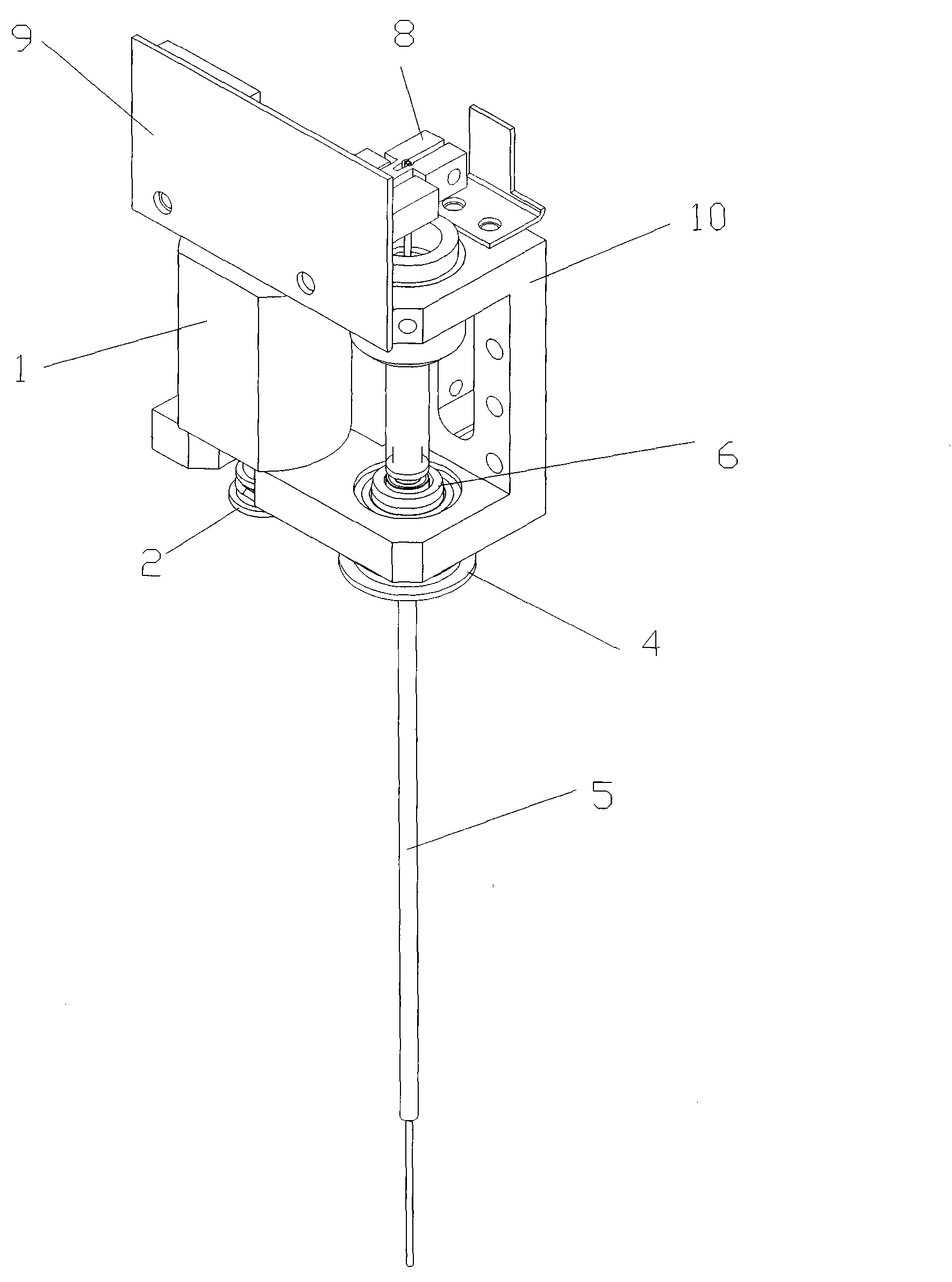

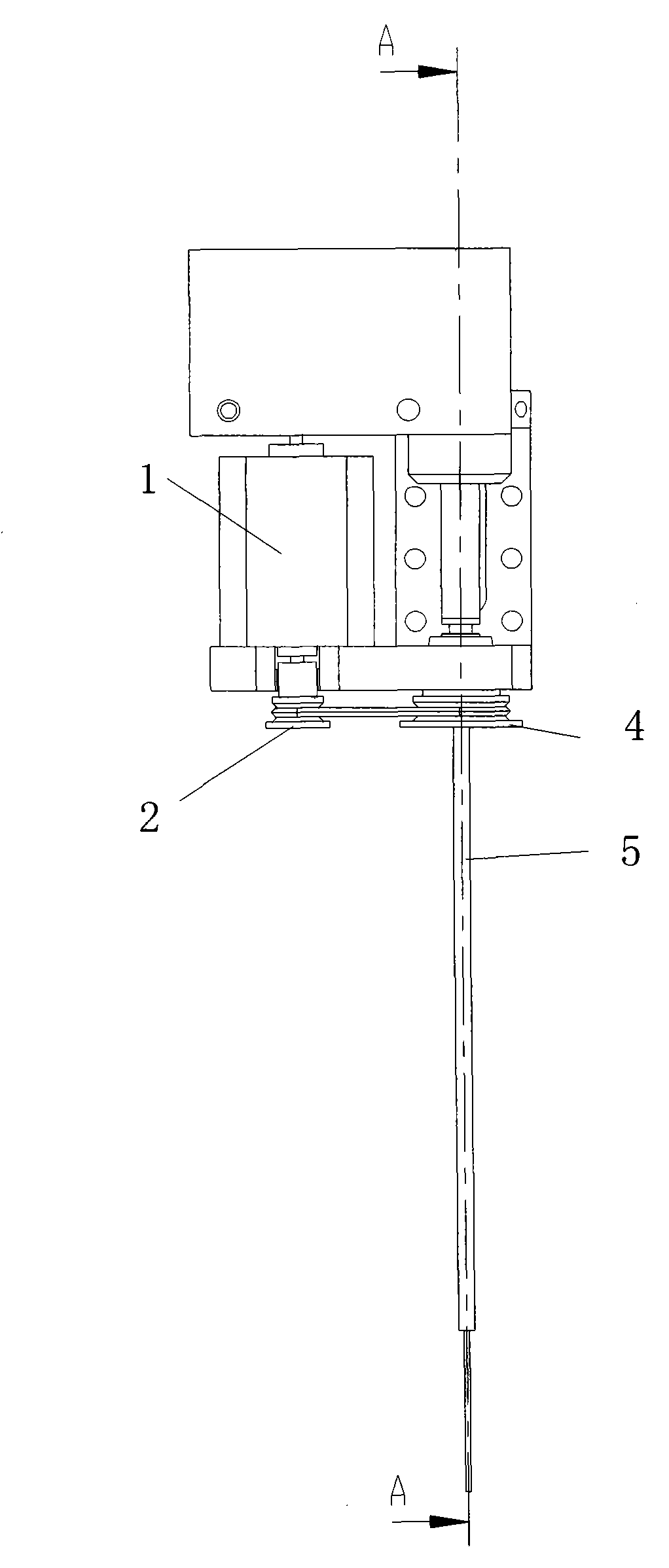

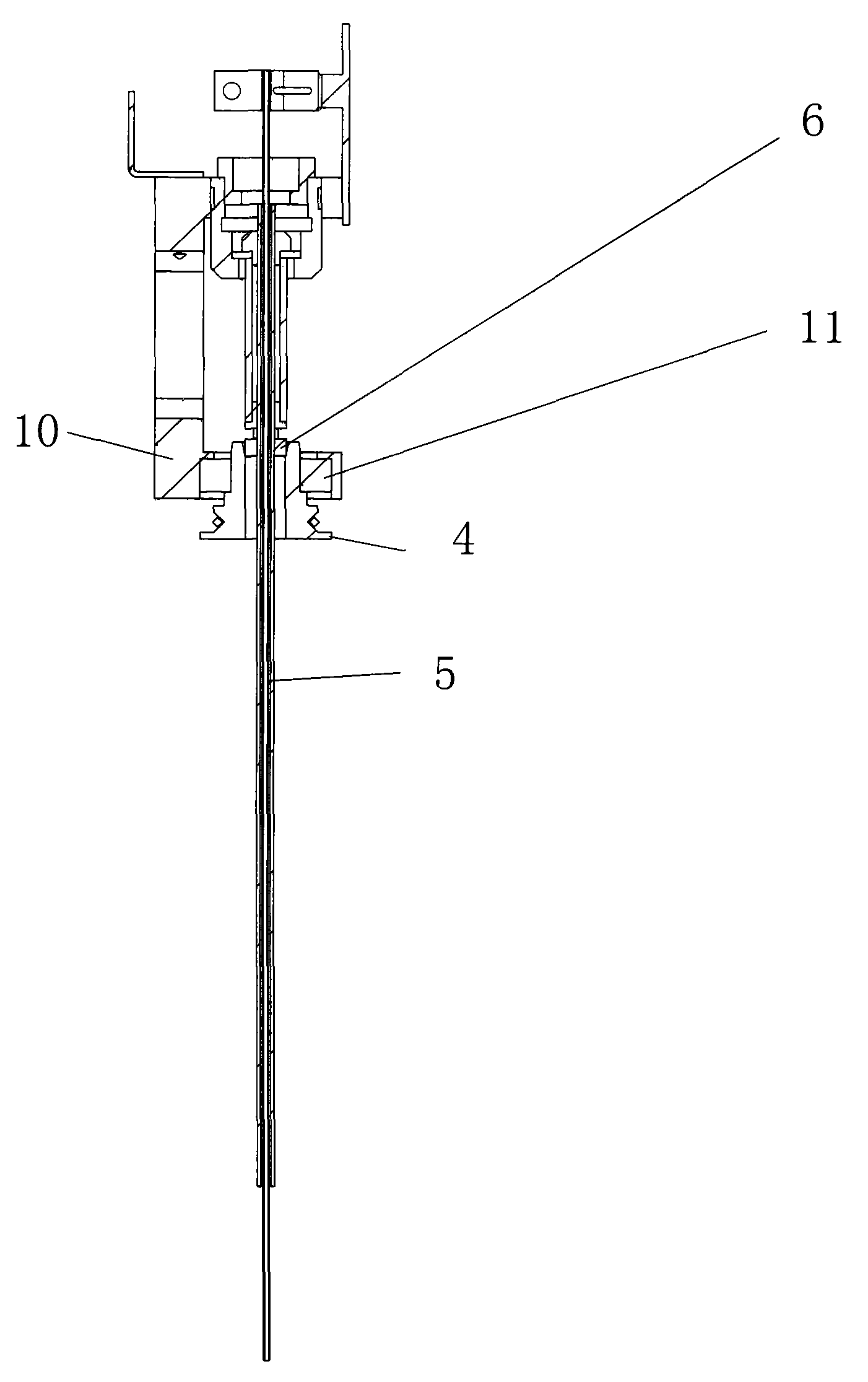

[0028] Such as Figure 1-3 , a method for simultaneously realizing sample needle sampling, sample addition and stirring, adopting an integrated sample needle sample adding and stirring device to realize liquid sample sampling, sample adding and stirring; the integrated sample needle sample adding and stirring device includes Fixed seat 10, stirring motor 1, driving wheel 2, eccentric wheel 4 and sample needle 5; stirring motor 1 is fixed on the fixed seat 10; eccentric wheel 4 is installed on the fixed seat 10 through the first bearing 11; sample needle 5 passes through the first Two bearings 6 are installed in the eccentric hole of the eccentric wheel 10;

[0029] The stirring motor 1 drives the eccentric wheel 4 to rotate through the driving wheel 2; the eccentric wheel drives the sample needle to generate stirring action, so that the sample needle stirs the liquid in the container while adding or sampling the sample.

[0030] Drive wheel 2 is connected with eccentric wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com