Sand discharge device and sand discharge method for ballast tank

A ballast tank and pump device technology, which is applied to the pipelines for emptying/ballasting, cleaning equipment for ship tanks, transportation and packaging, etc., can solve the problems of low efficiency, labor-consuming, time and cost difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

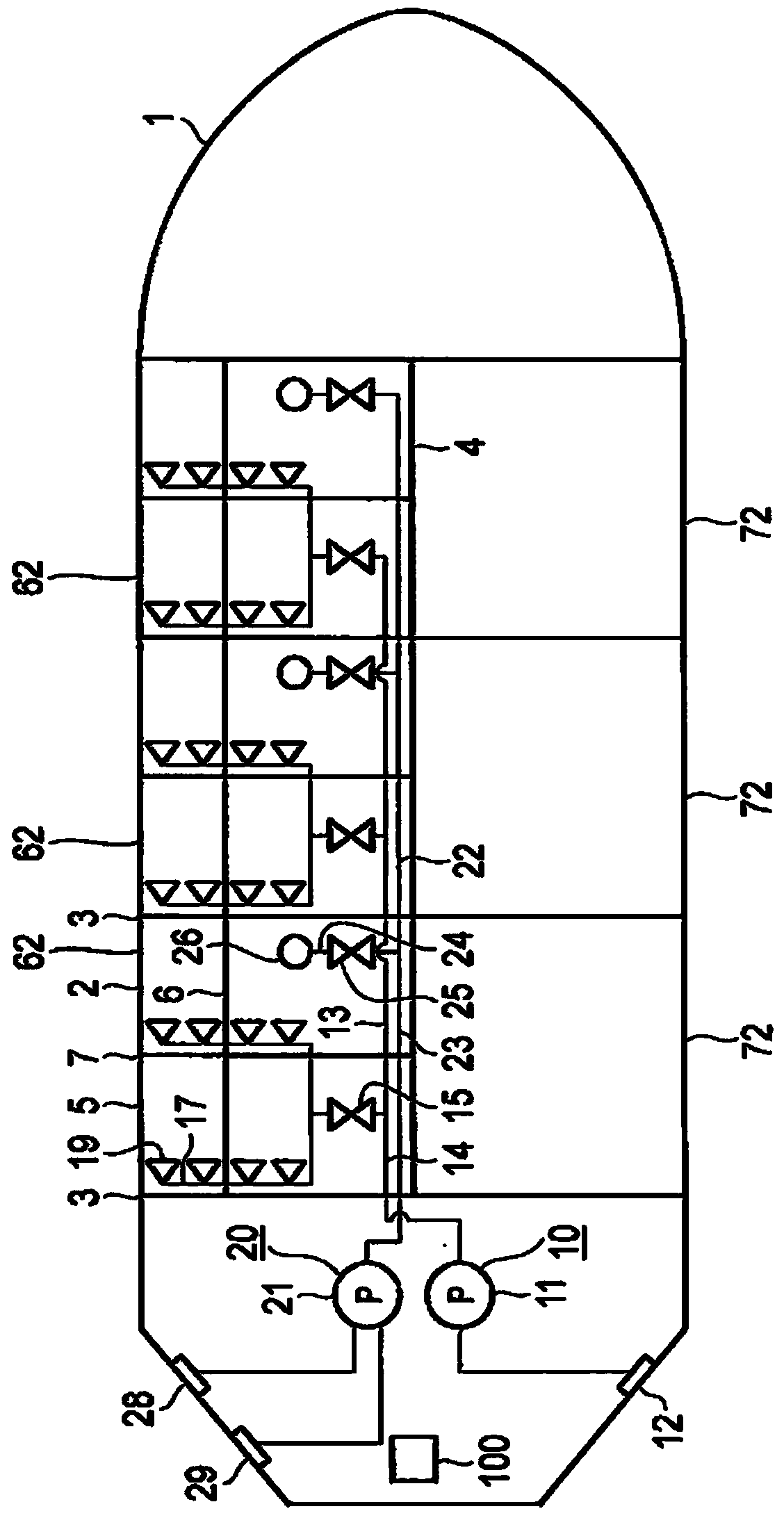

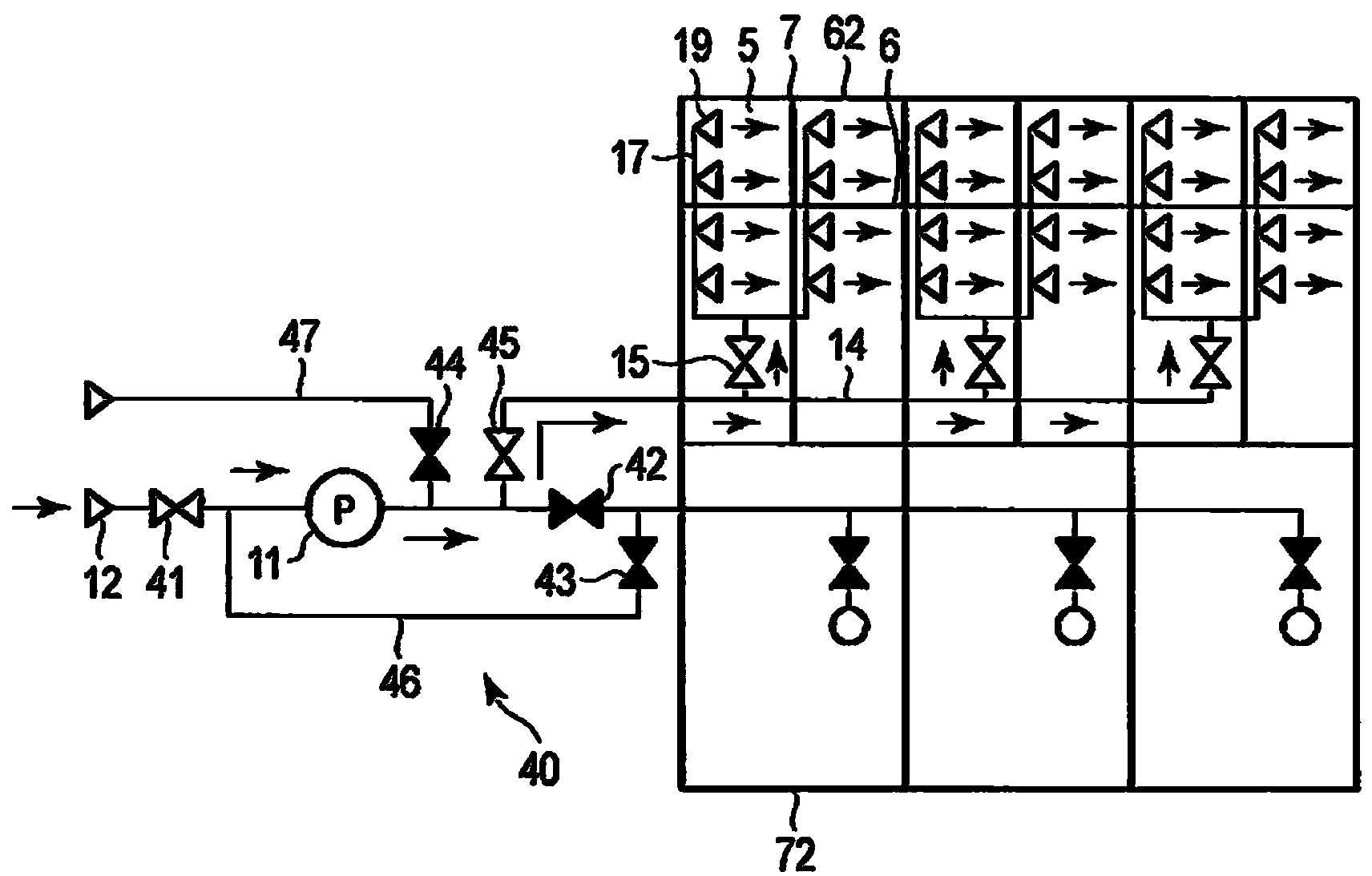

[0065] figure 1 It is a horizontal cross-sectional view showing the sand discharge device installed in the ballast tank 2 of the ship 1 as the first embodiment of the present invention.

[0066] On the ship 1 there are three ballast tanks 2 each along the length of the ship on the port side and on the starboard side. The ballast tank 2 has a port side ballast tank 62 and a starboard side ballast tank 72 . In addition, in figure 1 In , the device structure of the sand discharge device of the port ballast tank 62 is shown, and the device structure of the sand discharge device of the starboard side ballast tank 72 is omitted.

[0067] The ballast tanks 2 become closed spaces, and the closed spaces are surrounded by hull side plates, hull bottom plates, transverse bulkheads and longitudinal bulkheads between adjacent ballast tanks 2 . The internal space of the ballast tank 2 is divided into a plurality of compartments 5 by girders (longitudinal penetrating partitions) 6 and rib...

no. 2 approach

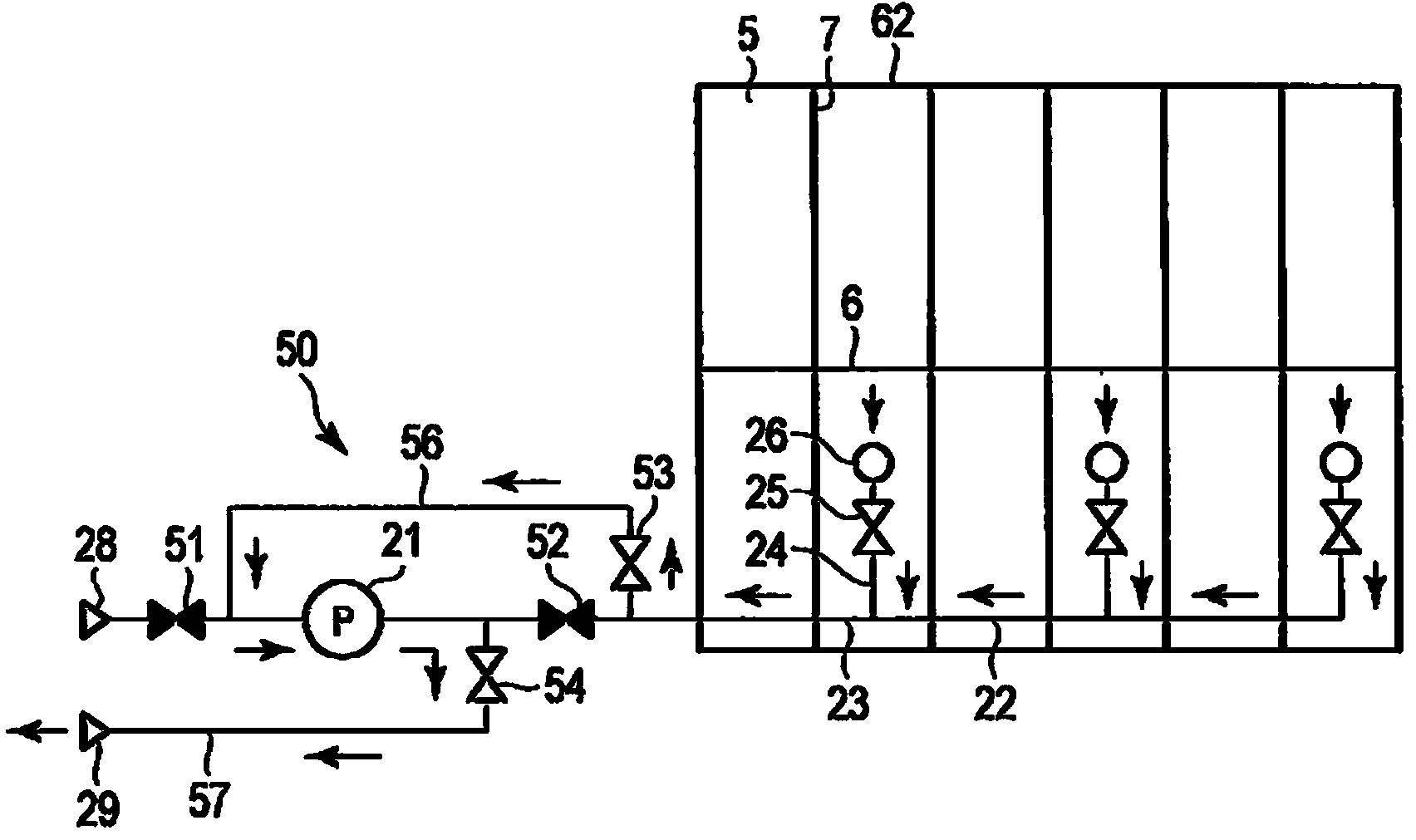

[0102] In the second embodiment, the means for spraying water from the nozzles and the means for discharging muddy water from the water injection port are the same as those in the first embodiment, and description thereof will be omitted.

[0103] Figure 6 is a sectional oblique view showing a compartment which is part of a ballast tank formed on the bottom of the ship, Figure 7A yes Figure 6 Sectional views of the compartments in the section extending along the length of the ship, and, Figure 7B yes Figure 6 The sectional view of the compartment extending along the ship's width direction.

[0104] The hull is formed as a double bottom, from Figure 6 It can be seen that there is a bottom plate 8 and an upper bottom plate 9 between which a ballast tank is formed. The internal space of the ballast tank is divided into a plurality of compartments 5 by girders (longitudinal penetrating partitions) 6 and ribs (horizontal plates) 7. The girders 6 extend along the length o...

no. 3 approach

[0123] In the third embodiment, the means for spraying water from the nozzles and the means for discharging muddy water from the injection water outlet are the same as those in the first embodiment, and description thereof will be omitted.

[0124] Figure 9 is a sectional oblique view showing a compartment which is part of a ballast tank formed on the bottom of the ship, Figure 10A yes Figure 9 Sectional views of the compartments in the section extending along the length of the ship, and, Figure 10B yes Figure 9 The sectional view of the compartment extending along the ship's width direction.

[0125] The hull is formed as a double bottom, from Figure 9 It can be seen that there is a bottom plate 8 and an upper bottom plate 9 between which a ballast tank is formed. The internal space of the ballast tank is divided into a plurality of compartments 5 by girders (longitudinal penetrating partitions) 6 and ribs (horizontal plates) 7. The girders 6 extend along the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com