Semiconductor device and semiconductor device manufacturing method

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as impossible to expect heat dissipation effect, achieve excellent productivity, reduce component cost, inventory Manage easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

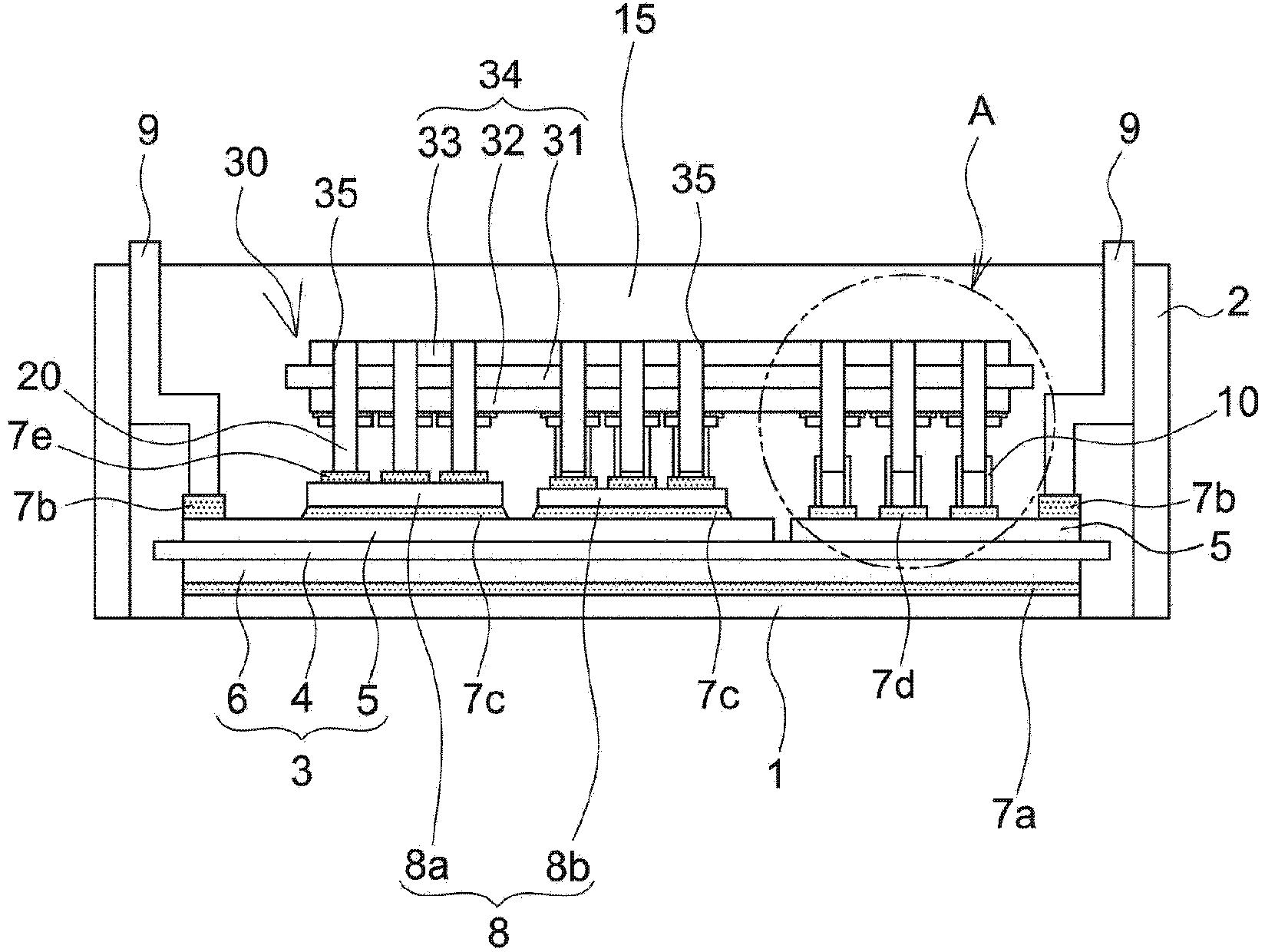

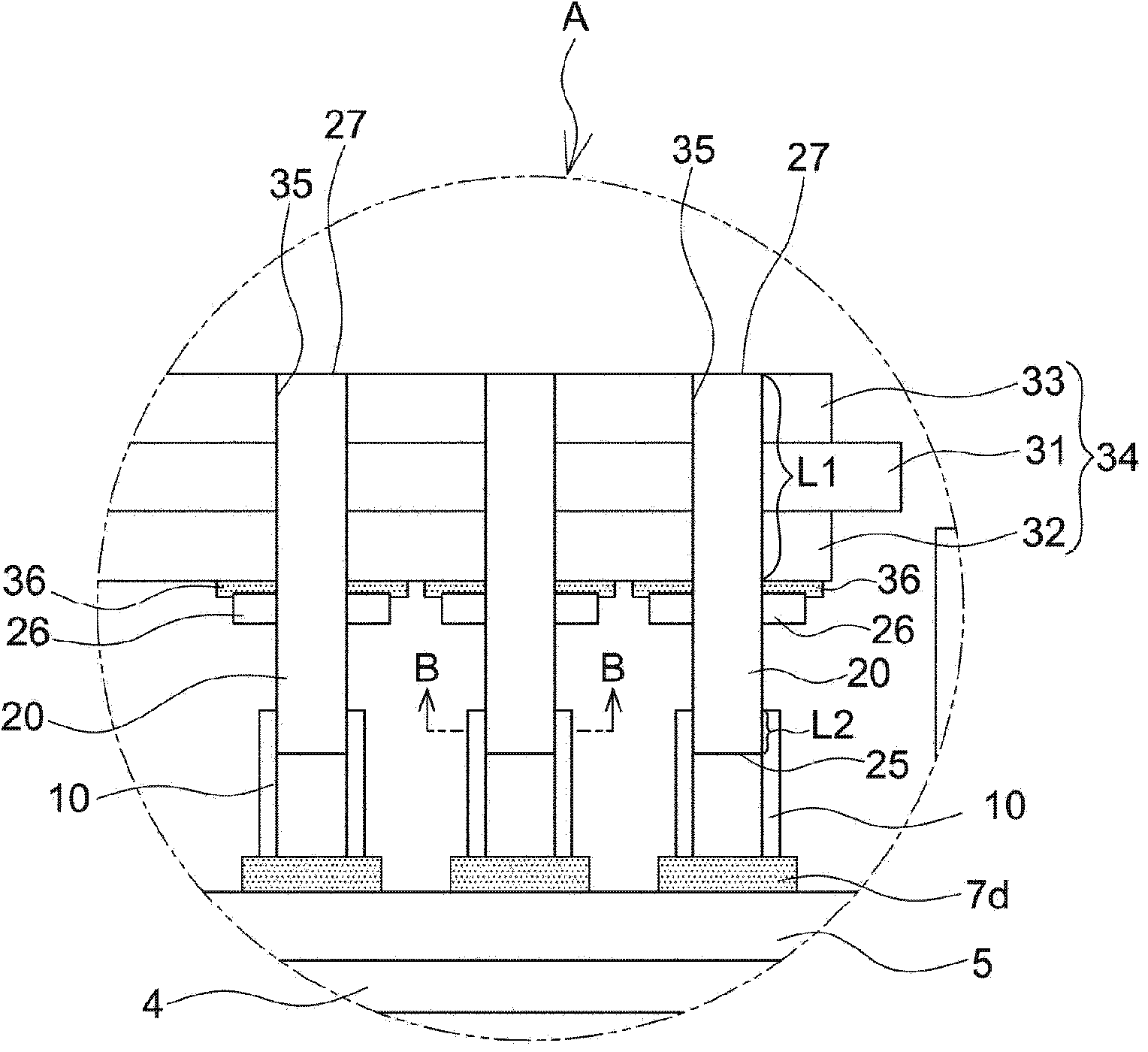

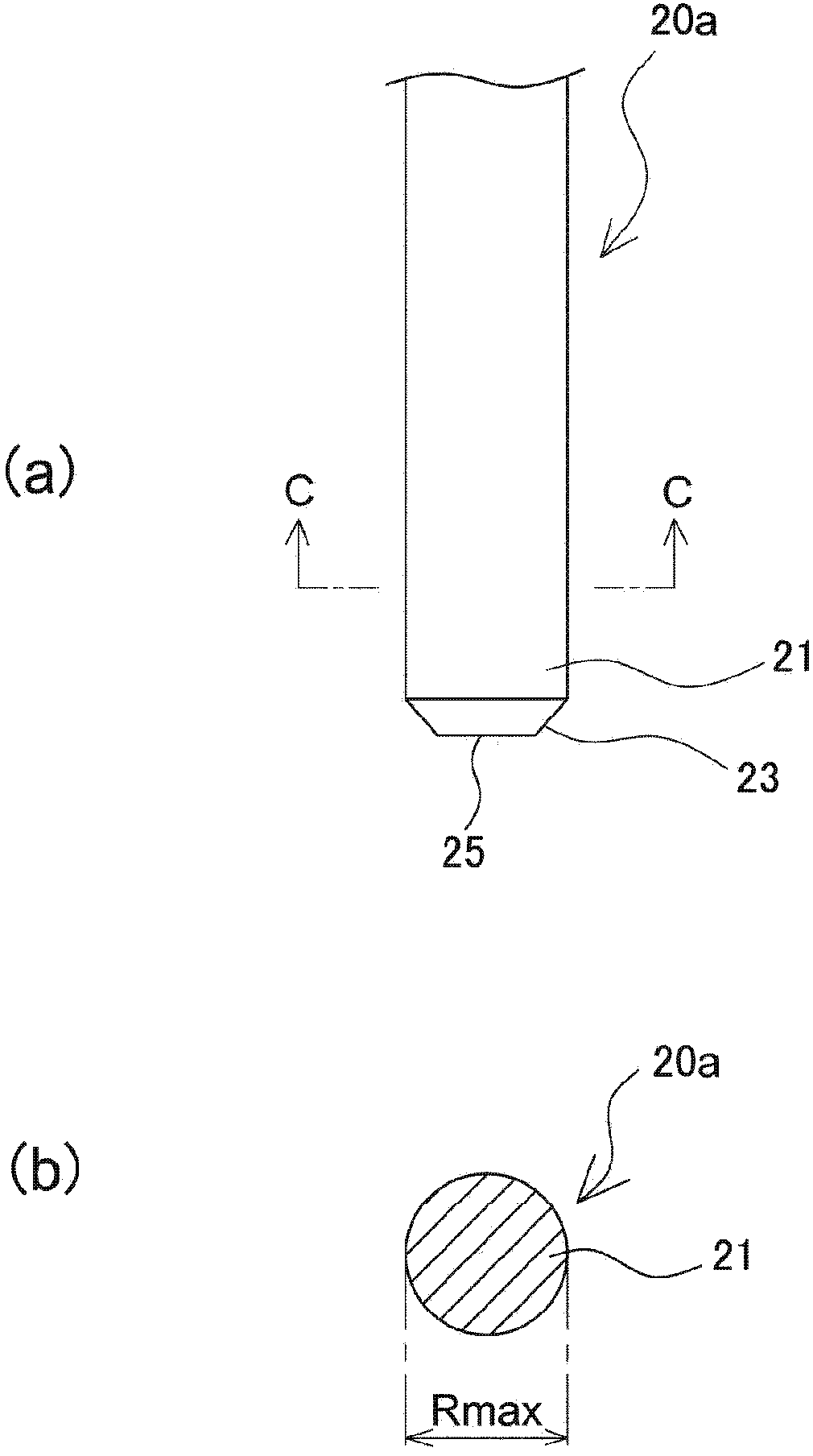

[0051] A semiconductor device according to the present invention will be described with reference to the drawings. figure 1 One embodiment of the semiconductor device of the present invention is shown.

[0052] In this semiconductor device, a cooling plate 1 is provided at the bottom of a resin case 2 . The cooling plate 1 is made of a material with high heat dissipation. For example, copper, aluminum, copper alloy, aluminum alloy etc. are mentioned.

[0053] An insulating wiring substrate 3 is provided on the cooling plate 1 . The insulating wiring board 3 is formed by bonding metal layers 5 and 6 to both surfaces of an insulating substrate 4 , and a predetermined circuit pattern is formed on the insulating substrate 4 using the metal layer 5 . Furthermore, the metal layer 6 of the insulating wiring board 3 and the cooling plate 1 are bonded via the solder or the sintering material layer 7a.

[0054] The insulating wiring board 3 is not particularly limited. For example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com