Pneumatic expandable combined precision seeder

A seeder and pneumatic technology, applied in the field of agricultural planting and sowing, can solve the problems of non-adjustable scale, poor precision sowing, seed waste, etc., achieve uniform seed distribution, ensure efficiency and stability, and reduce seed leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

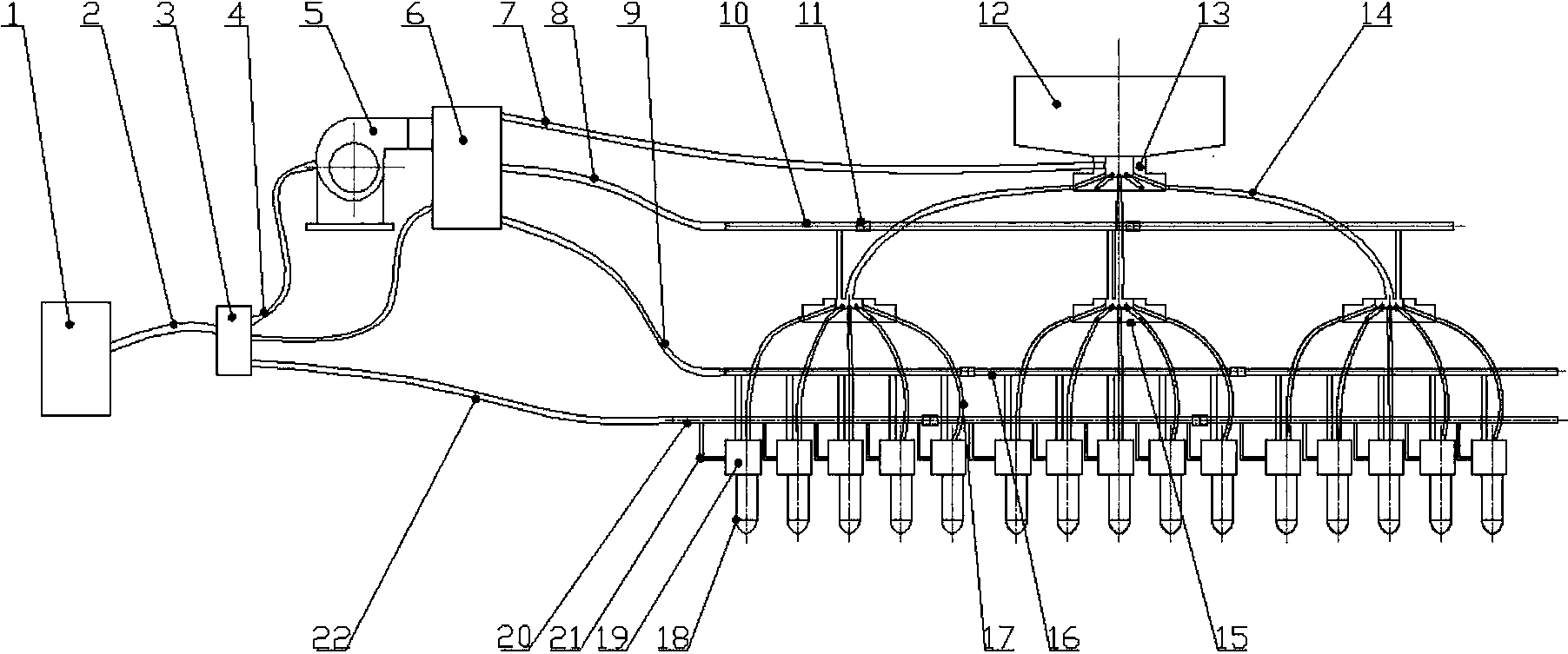

[0039] A pneumatic expandable combination precision seeder, such as figure 1 As shown, it includes seed distribution system, seed precision sowing system, air pressure system and feedback system.

[0040] The seed distribution system comprises a seed box 12, a first-level seed separator 13, a first-level seed guide tube 14, a second-level seed separator 15 and a second-level seed guide tube 17, and the first-level seed separator 13 is arranged at the outlet of the seed box 12. The seed outlet of the first-level seed separator 13 is connected with at least one first-level seed introduction pipe 14 simultaneously, and the outlet of the first-level seed introduction pipe 14 is connected to the seed inlet of the second-level seed separator 15 respectively, and the second-level seed separator 15 The seed outlet is connected to at least one secondary seed guide pipe 17 at the same time, and the seed distribution system performs secondary distribution to the seeds in the seed box 12;...

Embodiment 2

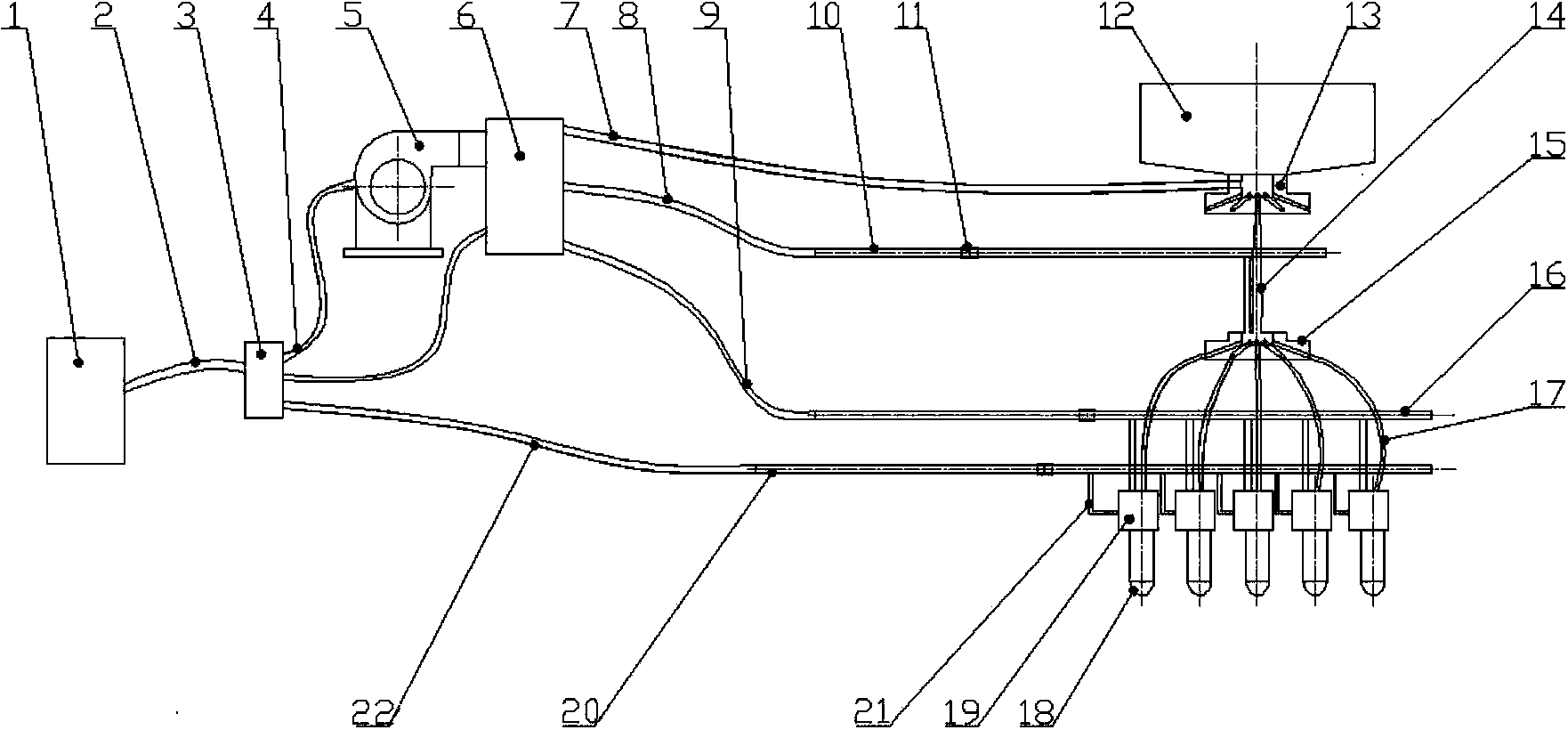

[0050] Such as figure 2 As shown, the difference from Embodiment 1 is that the pneumatic expandable combined precision seeder is a single group expansion structure, that is, the seed outlet of the first-stage seed separator 13 is connected to a first-stage seed guide pipe 14, and the first-stage guide The outlet of the seed pipe 14 is connected to the seed inlet of a secondary seed separator 15, and the seed outlet of the secondary seed separator 15 is connected to five secondary seed introduction pipes 17 at the same time.

Embodiment 3

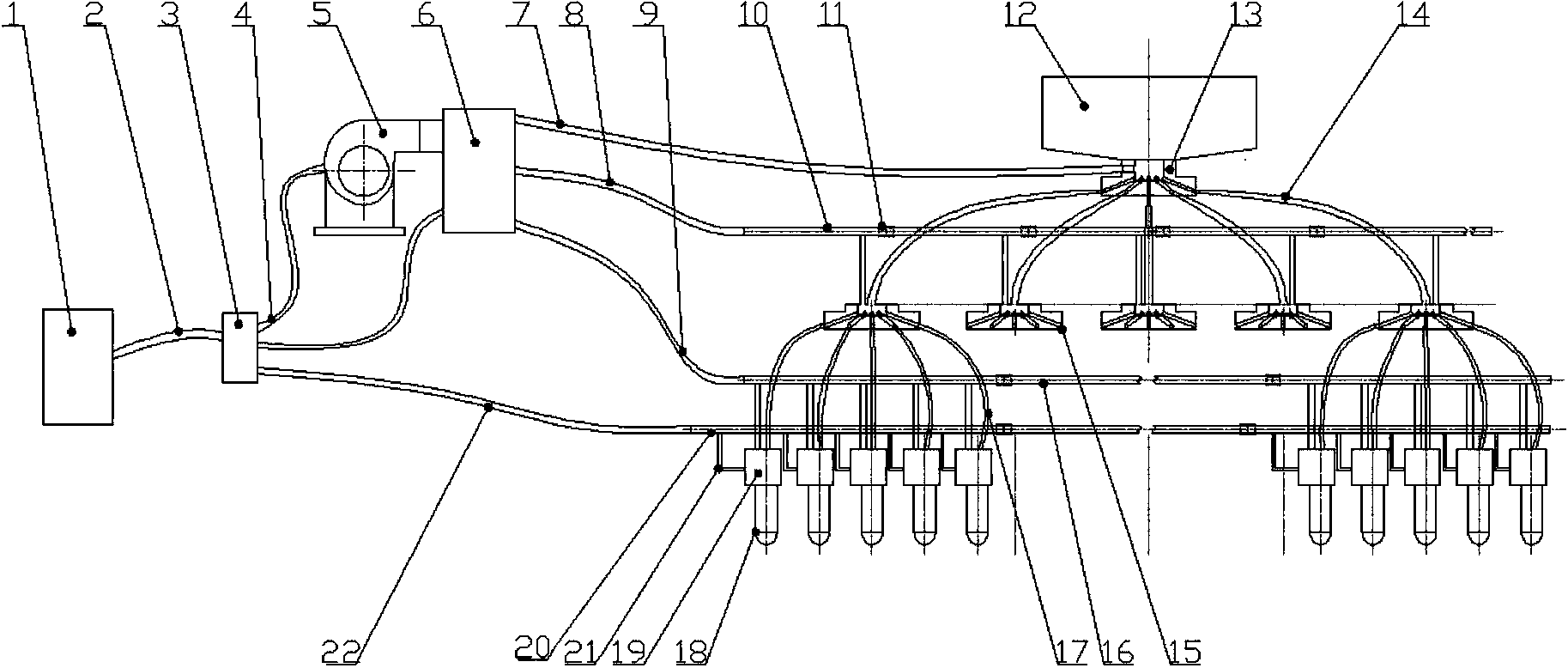

[0052] Such as image 3 As shown, the difference from Embodiment 1 is that the pneumatic expandable combined precision seeder has five sets of expansion structures, that is, the seed outlet of the first-level seed separator 13 is connected to five first-level seed guide pipes 14, and the first-level guide The outlet of the seed pipe 14 is connected to the seed inlets of five secondary seed separators 15 at the same time, and the seed outlet of the secondary seed separator 15 is connected to five secondary seed introduction pipes 17 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com