Cleaning method of mustard leaves before pickling

A technology of mustard and clear water, applied in the field of food processing, to achieve the effects of inhibiting oxidative browning, reducing waste, and reducing raw material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

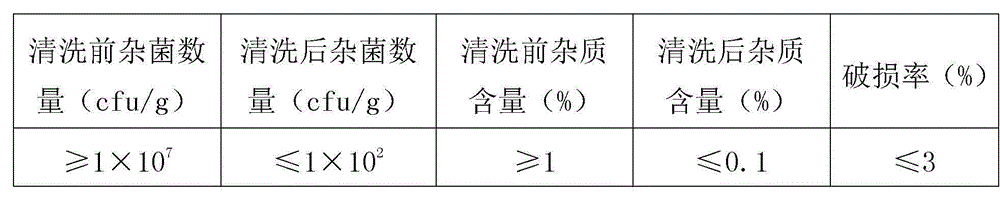

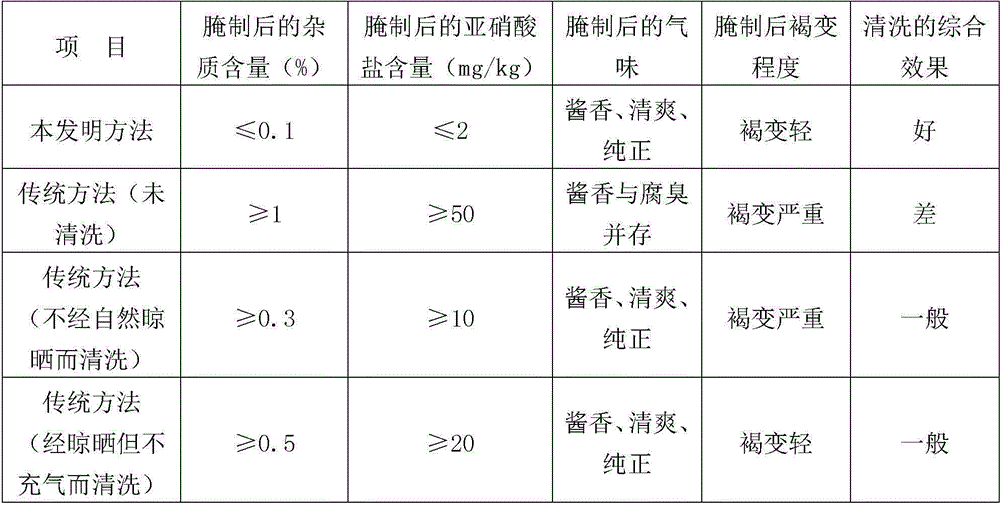

Embodiment 1

[0030] Cut the mustard greens 1-2 cm away from the ground, place them in the field or concrete ground in a single layer, and let them dry naturally for 2 days to reduce the water content to 65%-75%; remove the yellow leaves and rotten leaves from the dried mustard greens , placed in a clean water tank, poured into clean water to submerge the mustard greens, and let it soak for 10 minutes, so that the impurities on the surface of the green vegetables are easy to fall off after absorbing water, and the soaking water is cleaned and sand-filtered for repeated use. Take out the mustard greens and put them into another water tank, so that the mustard greens are completely submerged in clean water. Set a stainless steel vent pipe with a diameter of less than 5 mm at every 10 cm on the bottom of the water tank. The vent pipe is connected to the air outlet pipe of the air compressor. , Into the clear water into the compressed air pressure of 3MPa, so that the water is constantly turning...

Embodiment 2

[0032] Cut the mustard greens 1-2 cm away from the ground, place them in the field or concrete ground in a single layer, and let them dry naturally for 3 days to reduce the water content to 65%-75%; remove the yellow leaves and rotten leaves from the dried mustard greens , placed in a clean water tank, poured into clean water to submerge the mustard greens, and left to soak for 15 minutes, so that the impurities on the surface of the vegetable body were easy to fall off after absorbing water, and the soaking water was cleaned and sand-filtered for repeated use. Take out the mustard greens and put them into another water tank, so that the mustard greens are completely submerged in clean water. Set a stainless steel ventilation pipe with a diameter of less than 5 mm at every 20 cm at the bottom of the water tank. The ventilation pipe is connected with the outlet pipe of the air compressor. , into the clear water into the compressed air pressure of 0.6MPa, so that the water is con...

Embodiment 3

[0034]Cut the mustard greens 1-2 cm away from the ground, place them in the field or concrete ground in a single layer, and let them dry naturally for 1 day to reduce the water content to 65%-75%; remove the yellow leaves and rotten leaves from the dried mustard greens , placed in a clean sink, poured into clean water to submerge the mustard greens, and let it soak for 5 minutes, so that the impurities on the surface of the green vegetables would fall off easily after absorbing water, and the soaking water would be cleaned and sand-filtered for repeated use. Take out the mustard greens and put them into another water tank, so that the mustard greens are completely submerged in clean water. Set a stainless steel ventilation pipe with a diameter of less than 5 mm at every 30 cm at the bottom of the water tank. The ventilation pipe is connected with the air outlet pipe of the air compressor. , Into the clear water into the compressed air pressure of 2MPa, so that the water is cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com