Ultrasonic vibrating ice breaking hammer

An ultrasonic and ice-breaker technology, applied in sports accessories, fluids using vibration, equipment for mountaineering, etc., can solve the problems of huge physical strength, unsatisfactory effect, and inability to ensure that the parts of each hammer are completely consistent, etc. Guaranteed waterproof performance, increased hammering effect, and the effect of preventing short circuit phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

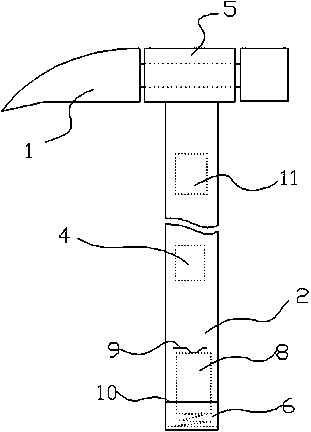

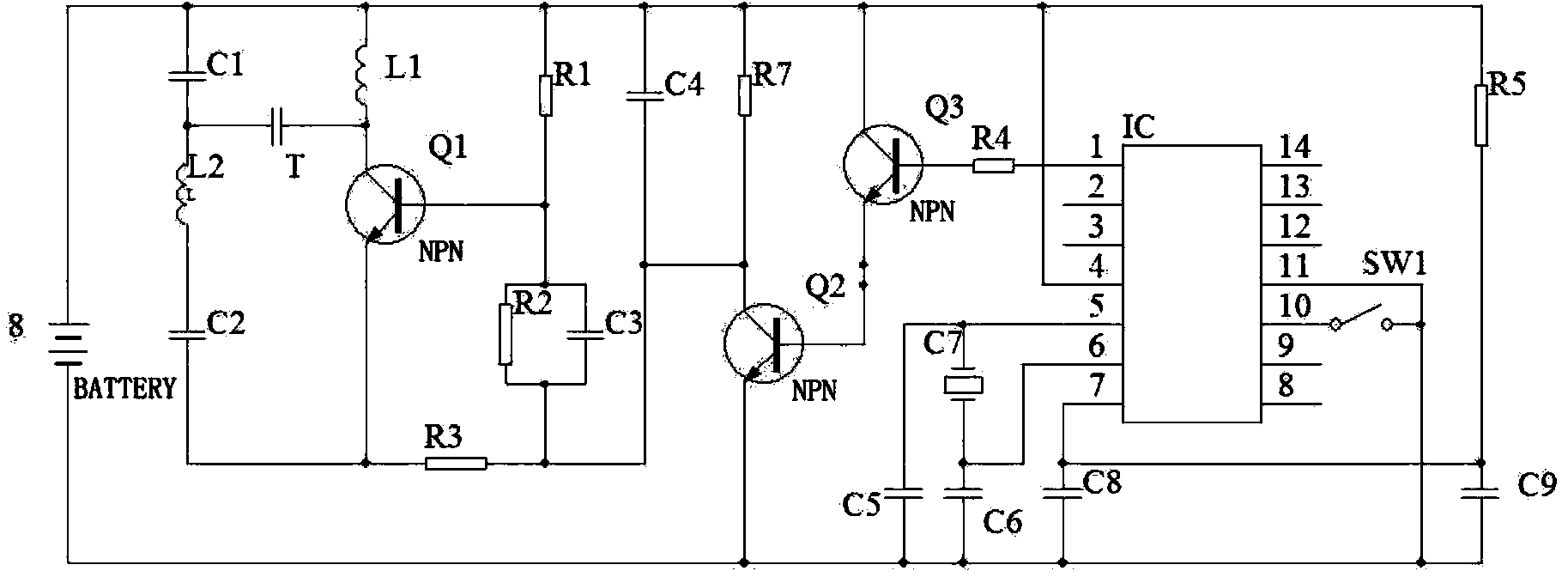

[0008] An ultrasonic vibration ice breaking hammer, such as figure 1 and figure 2 As shown, it includes ice breaking hammer head 1, hammer handle 2, ultrasonic transducer 5, circuit board 4 and start trigger 11. The hammer handle 2 is formed by engaging the upper shell of the hammer handle and the lower shell of the hammer handle and inserted into the base of the battery door. 6 is fixed, and the ultrasonic transducer 5 is fixed on the icebreaker Bing 2. In this embodiment, the ultrasonic transducer adopts a magnetostrictive transducer, and the magnetic core of the magnetostrictive transducer is formed by stacking sheets. Moreover, the magnetic sheet is treated at high temperature to form a dark green oxide layer, so that a good insulation state is ensured between the sheets. In this embodiment, the magnetostrictive transducer and the hammer head 1 are designed as an integrated structure, and the nickel Magnetostrictive material is made of sheets, the sheet size is 0.05-0.2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com