Method for reducing volatile organic contaminant residue in soil in mechanical ventilation repair process

A volatile organic and mechanical ventilation technology, which is applied in the field of remediation of polluted soil, can solve the problems of easy volatilization and small range of pollutants, and achieve the effects of saving costs, speeding up the repair of volatiles, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

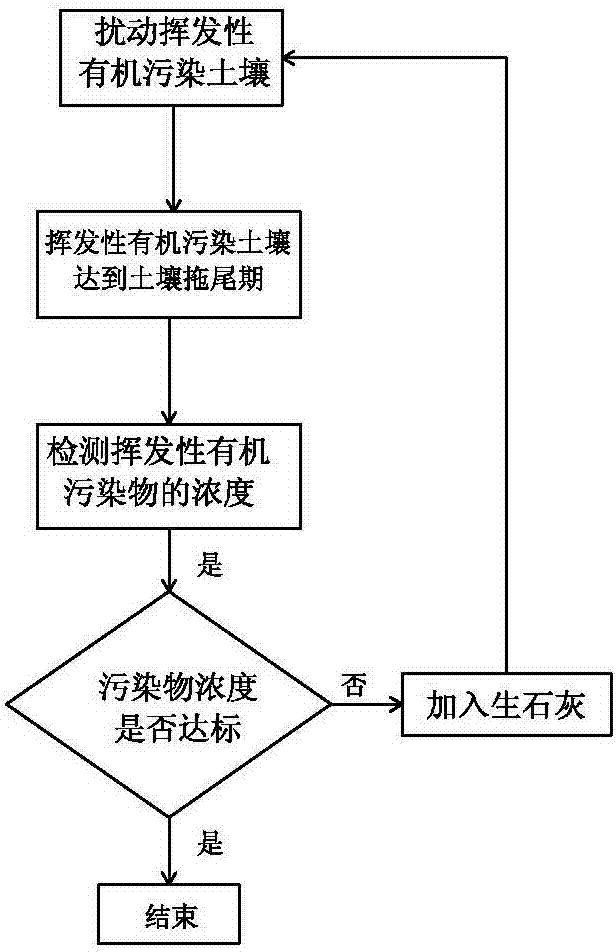

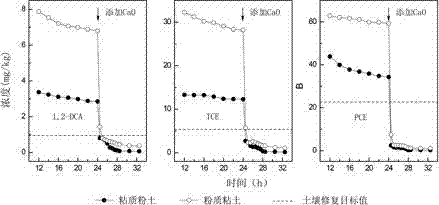

[0038] Such as figure 1 As shown, a method for reducing the residual volatile organic pollutants in the soil of the mechanical ventilation repair process provided by the embodiment of the present invention first disturbs the volatile organic polluted soil to fully volatilize the volatile organic pollutants in the volatile organic polluted soil ; When the volatile organic polluted soil enters the remediation tailing period, detect the concentration of volatile organic pollutants in the volatile organic polluted soil; collect soil samples at a certain time interval during the disturbance process, and a part of the gas pollutants is collected by the activated carbon filter device After treatment, it is discharged into the atmosphere, and the other part is connected to a portable gas chromatograph for real-time monitoring and analysis of gas components and concentrations; if the concentration of volatile organic pollutants exceeds the restoration target value, add quicklime to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com