Single wheel combined rolling guide groove

A combination and guide groove technology, which is applied in the field of rolling guide grooves and single-wheel combined rolling guide grooves, can solve problems such as scratches on rolled pieces and short service life of guide grooves, and achieve cost reduction and convenient inspection and replacement of guide grooves , The effect of ingenious overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

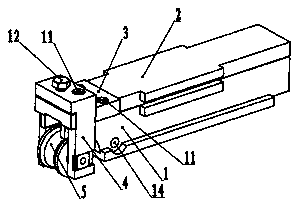

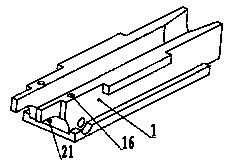

[0023] Example 1 : see figure 1 , a single-wheel combined rolling guide groove, including a guide groove 1 and a guide groove cover 2, the guide groove cover 2 is arranged on the upper part of the guide groove 1, and the rolling guide groove also includes a guide wheel 5 located at one end of the guide groove And the guide wheel bracket 4 and the bracket fixing block 3 that are arranged on the guide wheel 5 top, the described guide wheel bracket 4 and the bracket fixing block 3 are provided with adjusting bolts 12, and the guide wheel bracket 4 is clamped on the bracket fixing block 3 card slot. The technical scheme is ingeniously designed and has a protective effect on the surface of the rolled piece, without scraping and sticking of steel, and no scratches on the surface of the rolled piece, and is conducive to reducing the cost of the guide groove.

Embodiment 2

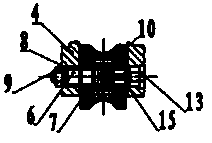

[0024] Example 2 : see figure 1 , figure 2 , as an improvement of the present invention, the rolling guide groove further includes a guide wheel shaft 6 , and the guide wheel shaft 6 passes through the guide wheel 5 . The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0025] Example 3 : see figure 2 , as an improvement of the present invention, two bearings 7 are arranged symmetrically on both sides of the guide wheel 5, and an oil-gas distributor 10 is installed between the two bearings 7. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com