Device for shifting rapid transfer trolley wheels of transverse marshalling rack

A technology of shifting device and marshalling table, which is applied in the direction of conveyor, mechanical conveyor, transportation and packaging, etc. It can solve the problem of affecting the normal production rhythm of the rolling line, the service life of equipment, the high failure rate of rolling equipment, and the tipping of trolleys. and other problems, to achieve the effect of solving the problem of trolley overturning, convenient disassembly, assembly, maintenance and replacement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

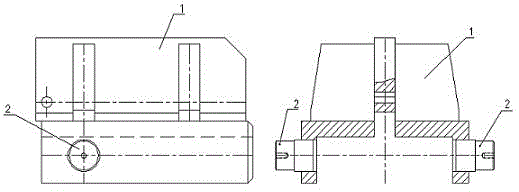

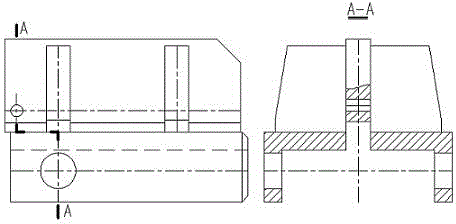

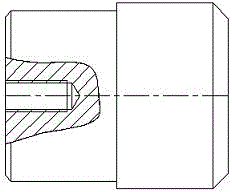

[0016] Embodiment 1: as figure 1 — image 3 , the wheel shifting device for the rapid transfer trolley of the traversing marshalling platform, including an extended support 1, a support roller shaft 2, and a fast transfer trolley wheel, the extended support 1 is fixedly connected with the support roller shaft 2, and the support roller shaft 2 Mounted on quick shift trolley wheels. The design of the whole technical scheme is ingenious and practical, which not only solves the problem of trolley overturning during steel production, but also reduces the failure rate of equipment.

Embodiment 2

[0017] Embodiment 2: as figure 1 — image 3 , as an improvement of the present invention, the number of the support roller shafts 2 is two. The wheel shifting device is mainly used for shifting the trolley wheels below the cantilever end, and the number of trolley wheels below the cantilever is 2, so the number of the support roller shafts is consistent with it. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0018] Embodiment 3: as figure 1 — image 3 , as an improvement of the present invention, when installing the extension bracket 1 and the bracket roller shaft 2, it is necessary to ensure that the concentricity of the two bracket roller shafts 2 is consistent. This can reduce the breakage phenomenon of the support roller shaft 2, thereby ensuring a longer service life of the wheel displacement device. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com