Yarn spinning mechanism

A yarn and yarn storage technology, which is applied to spinning machines, textiles, papermaking, jointing devices, etc., can solve the problems of low efficiency and long operation time of splicing trolleys, and achieve simple overall structure design and reduce splicing Operation time and quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] refer to Figure 1 to Figure 11 The specific implementation of a yarn spinning mechanism of the present invention will be further described. In addition, "upstream" and "downstream" in this specification are actually upstream and downstream of the running direction of the yarn during spinning.

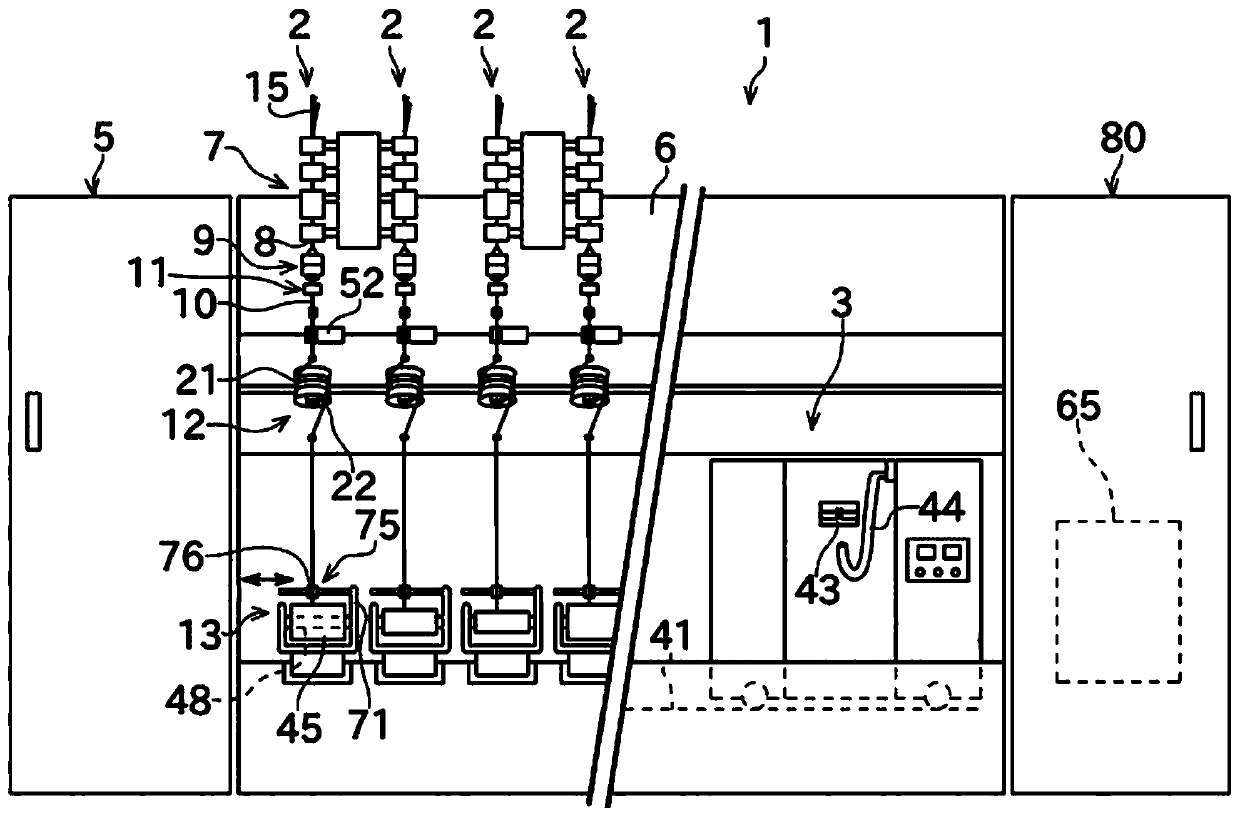

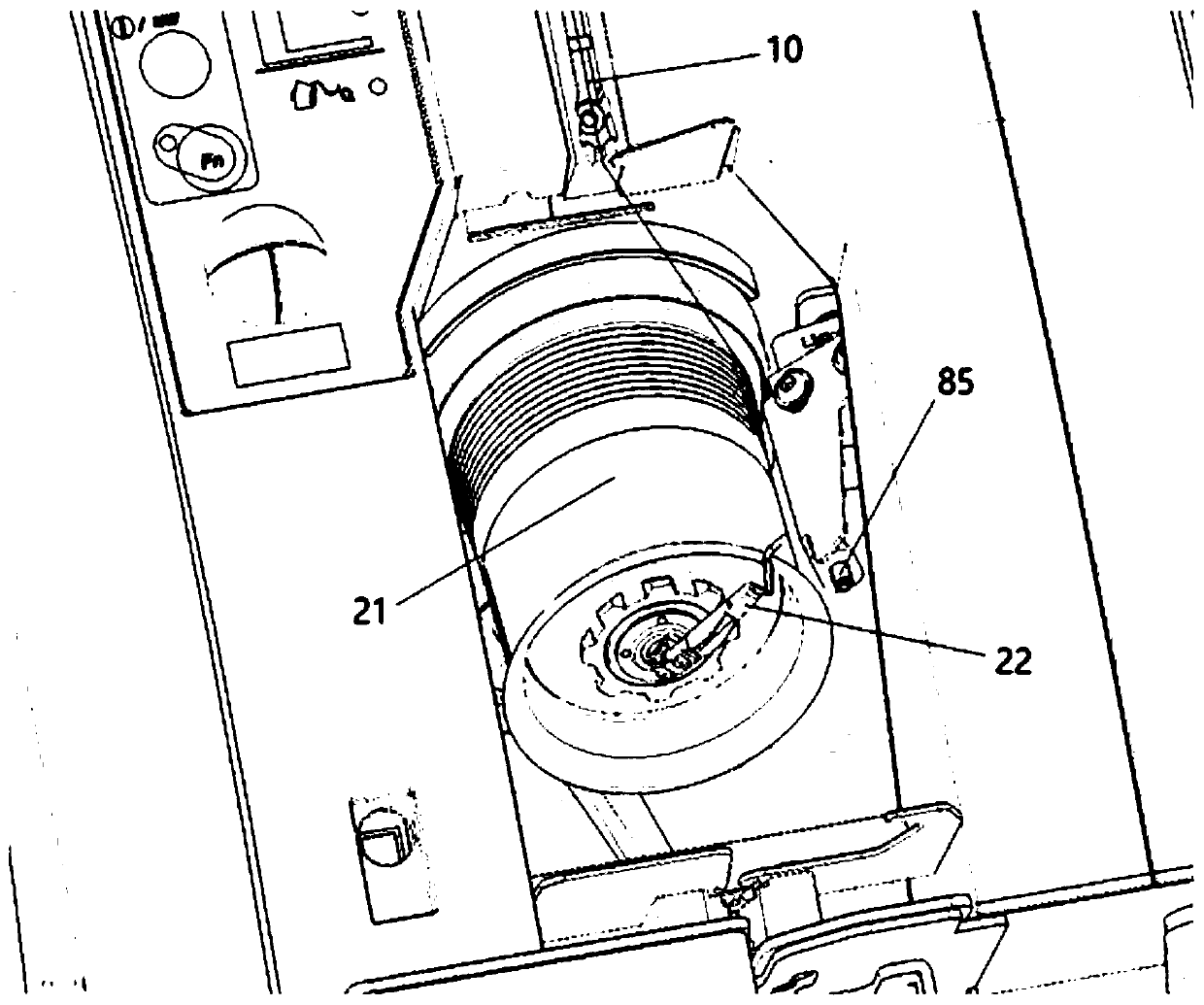

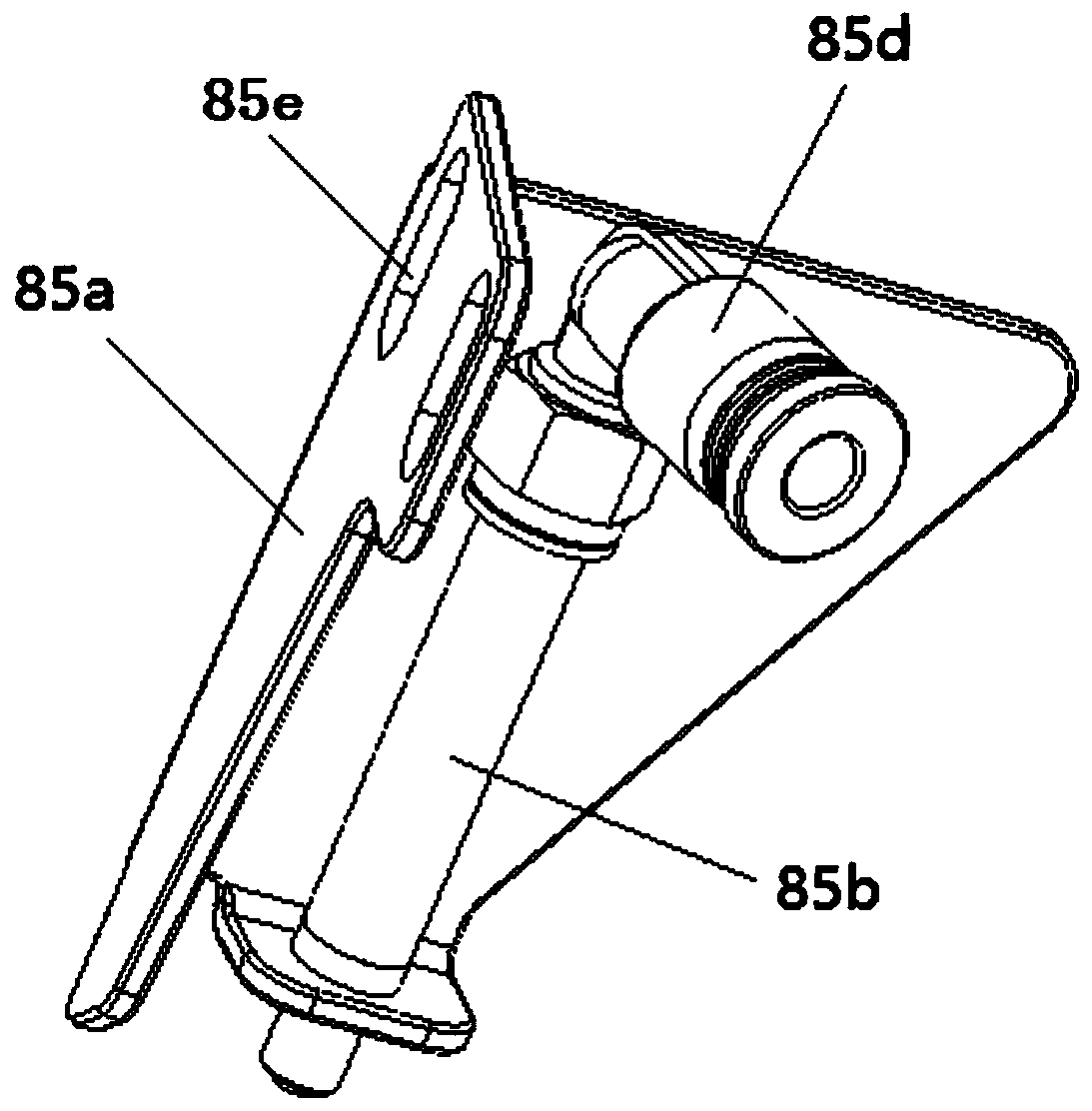

[0035] Such as figure 1 As shown, the fiber spinning machine 1 is provided with a plurality of spinning mechanisms 2 arranged in a row, and the spinning machine 1 has a splicing operation trolley 3, a negative pressure fan 80, and a control unit 5 installed on the headstock. Each spinning mechanism 2 is provided with a drafting device 7, a spinning part 9, an output device 11, a yarn storage device 12, and a winding part 13 as a main mechanism in sequence from upstream to downstream, and the yarn storage device 12 includes a yarn storage roller 21 And the yarn guide flyer 22, one side of the yarn guide flyer 22 is provided with a retractable and movable flyer stopper 85, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com