U-shaped infolding rotating mechanism with combination of inner chute and semicircle

A rotating mechanism and semi-circular arc technology, which is applied in the direction of mechanical equipment, shafts, bearings, pivots, etc., can solve the problems of inconvenient industrial manufacturing and large number of spare parts, and achieve the effect of simple and effective overall structure design and easy industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

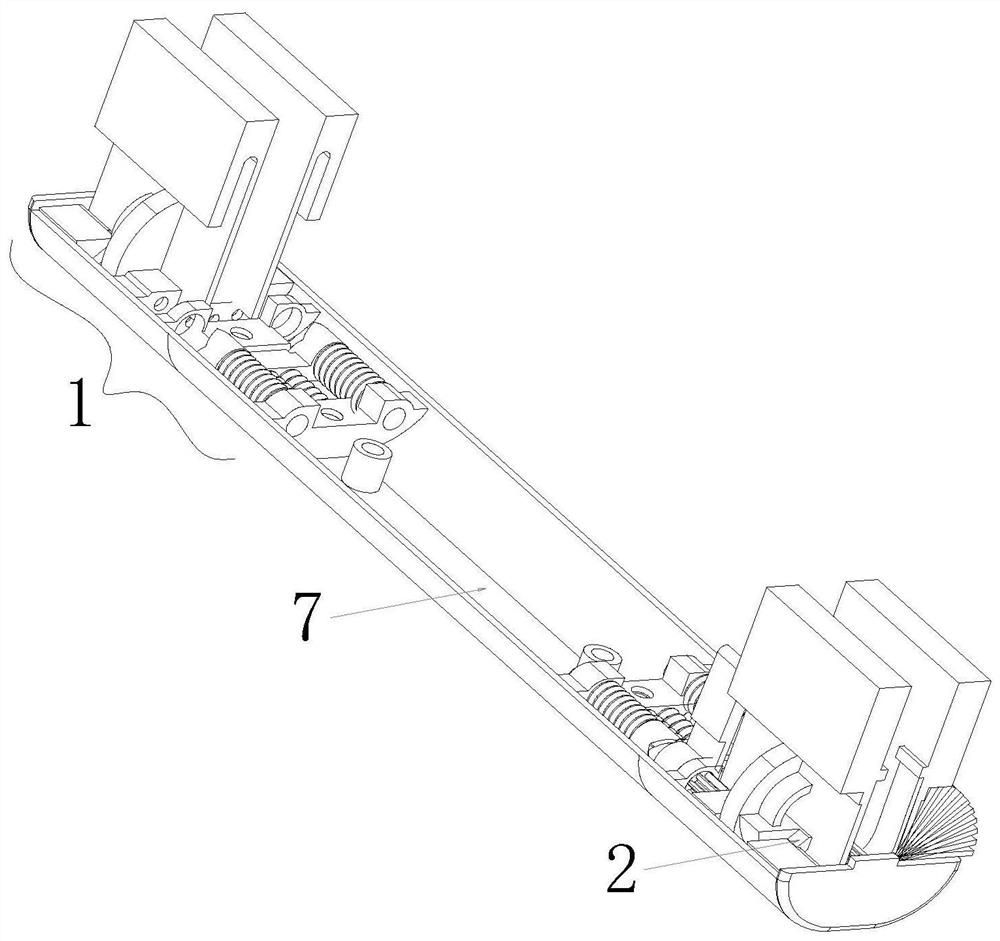

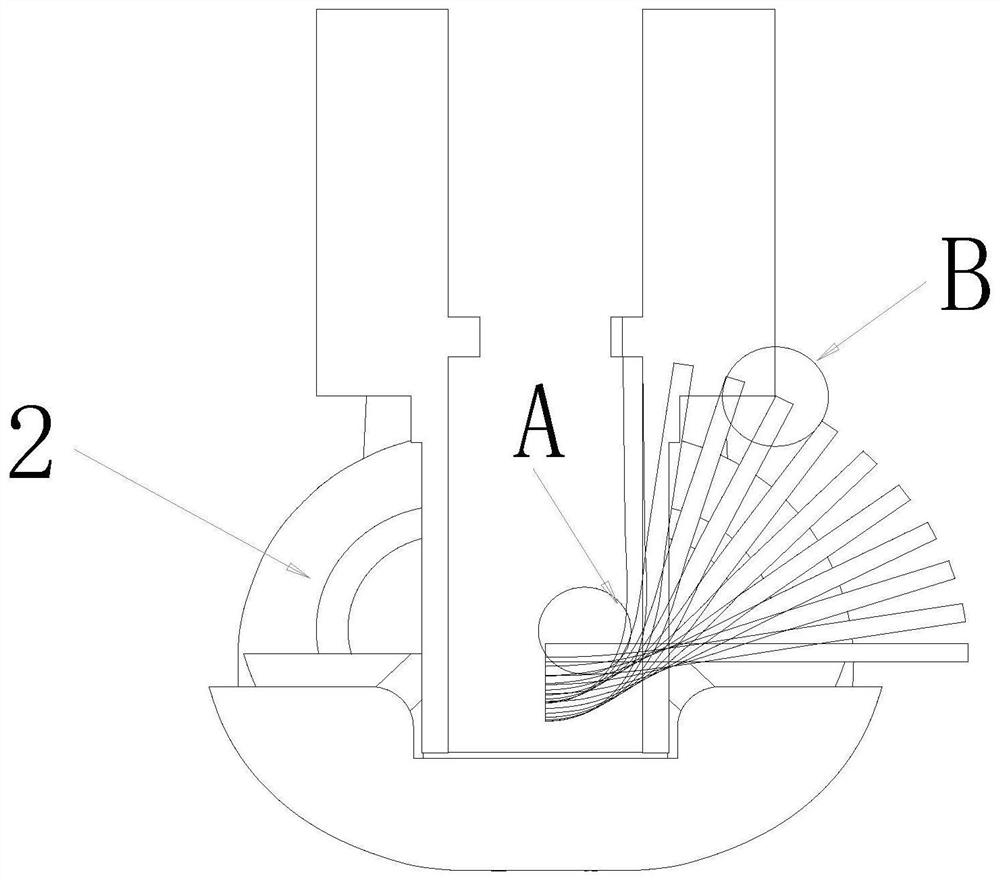

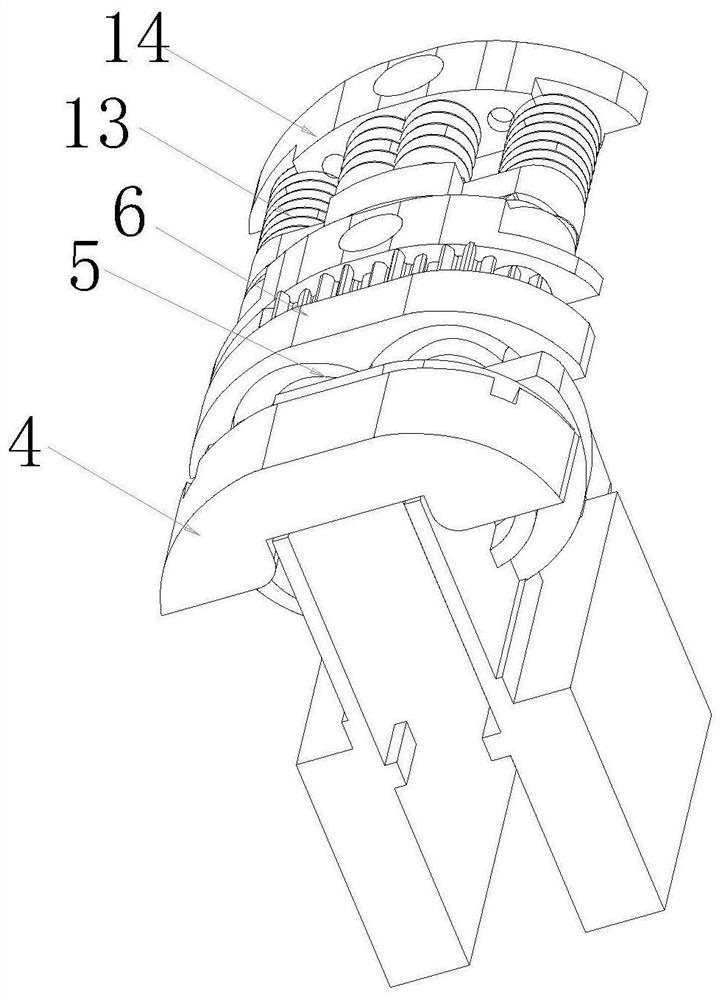

[0047] like Figure 8-16 As shown, the U-shaped inward turning mechanism disclosed in this embodiment, which combines an inner chute and a semicircular arc, includes a rotating shaft 1, and the rotating shaft 1 includes a rotating mechanism 2, and the rotating mechanism 2 includes two groups of horizontally distributed rotating mechanisms. Frame 3 and vertically distributed chute movable block 4, connecting and positioning movable block 5, two groups of interactive blocks 6 distributed horizontally are provided between the described chute movable block 4 and the described connecting and positioned movable block 5, and the interactive block 6 Both sides are respectively provided with oblique sliders 61 and arc-shaped grooves 62, two groups of inner inclined grooves 41 are arranged on the movable block 4 of the chute respectively, and the turret 3 is provided with arc-shaped sliders 31. The arc-shaped slider 31 slides in the arc-shaped groove 62, and the oblique slider 61 slides...

Embodiment 2

[0050] like Figure 9-25As shown, the U-shaped inward turning mechanism disclosed in this embodiment, which combines an inner chute and a semicircular arc, includes a rotating shaft 1, and the rotating shaft 1 includes a rotating mechanism 2, and the rotating mechanism 2 includes two groups of horizontally distributed rotating mechanisms. Frame 3 and vertically distributed chute movable block 4, connecting and positioning movable block 5, two groups of interactive blocks 6 distributed horizontally are provided between the described chute movable block 4 and the described connecting and positioned movable block 5, and the interactive block 6 Both sides are respectively provided with oblique sliders 61 and arc-shaped grooves 62, two groups of inner inclined grooves 41 are arranged on the movable block 4 of the chute respectively, and the turret 3 is provided with arc-shaped sliders 31. The arc-shaped slider 31 slides in the arc-shaped groove 62, and the oblique slider 61 slides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com