Folding mechanism and scooter

A folding mechanism and folding tube technology, applied in foldable bicycles, motor vehicles, bicycles, etc., can solve the problems of rust, inability to fold, personal injury, etc., and achieve a simplified overall structure design, less interference from the external environment, and convenient storage. and management effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

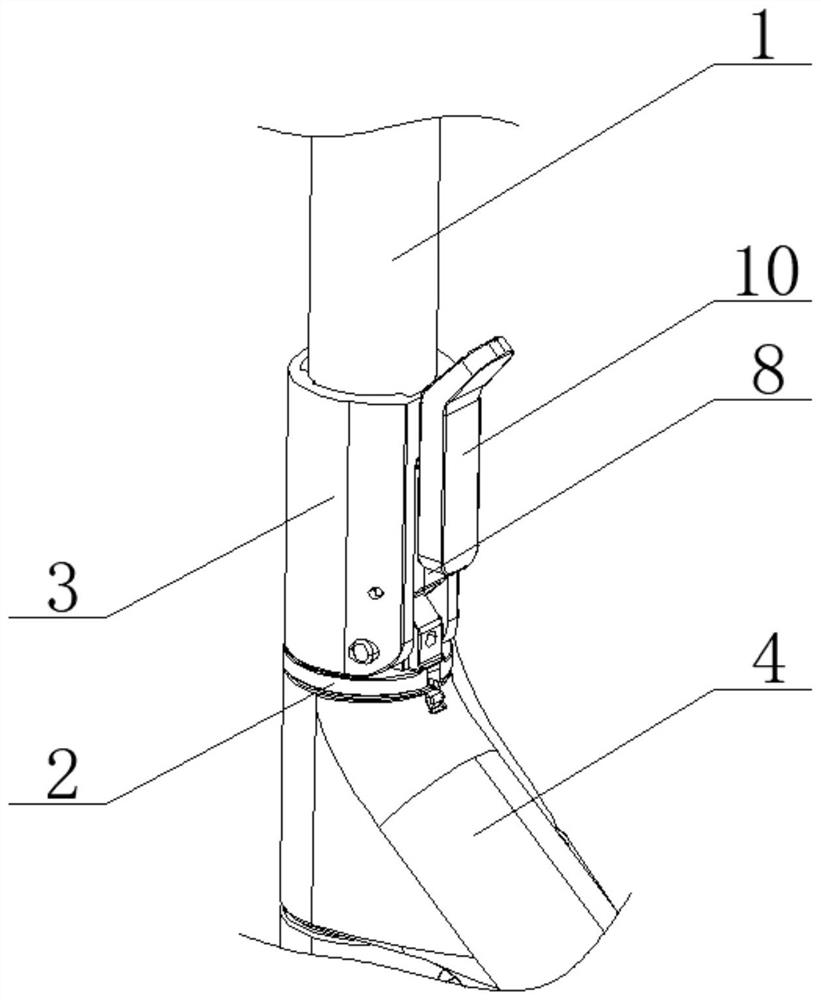

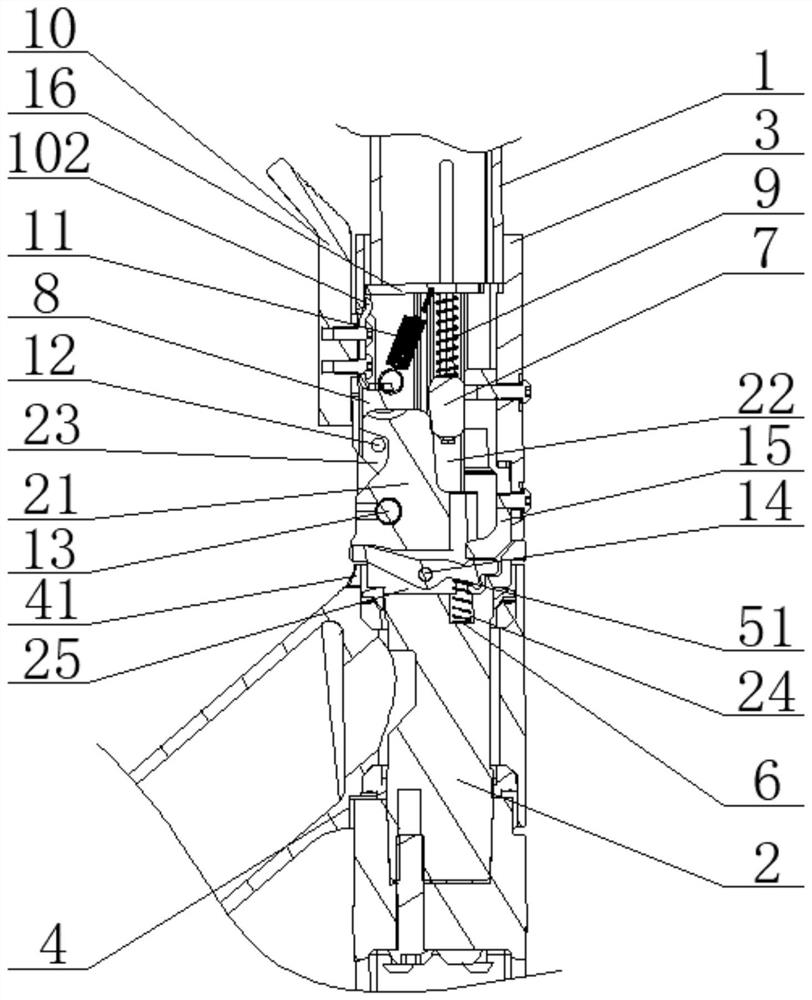

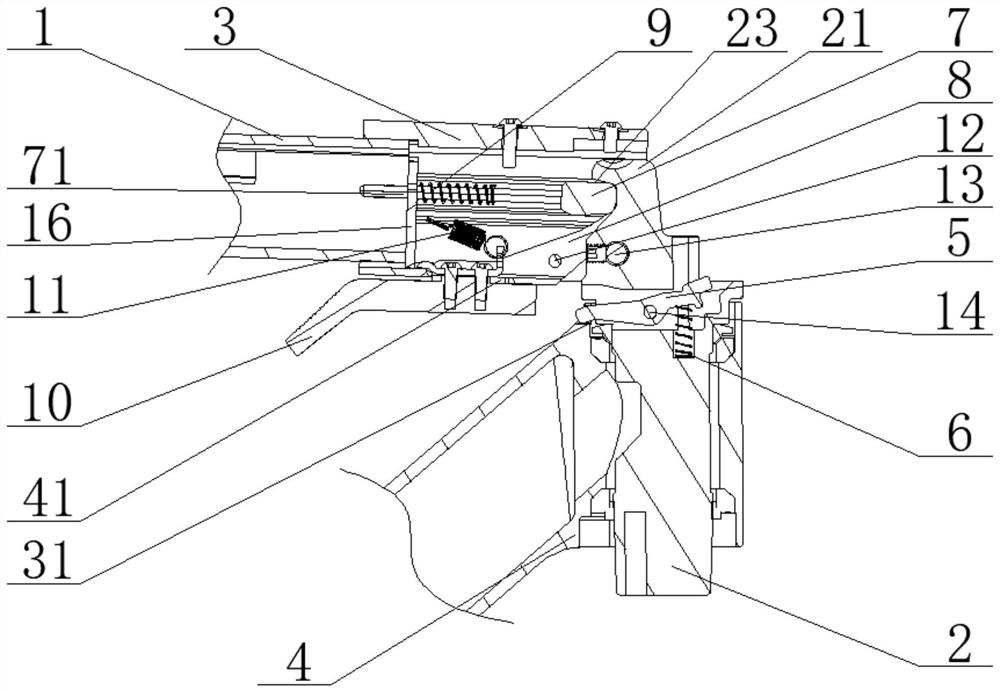

[0026] combined with Figures 1 to 4 , the technical solution of the present invention is a folding mechanism, including a headstock bar 1, a base 2, a folding tube 3 and a bracket 4, the base 2 is connected to the bracket 4, and the folding tube 3 passes through a second rotating shaft 13 Connected to the base 2, the headstock bar 1 is connected to the folding tube 3, the base 2 is connected to the first seesaw 5 and the spring 6, and the inner wall of the folding tube 3 is fixed with a limit block 15 , the bracket 4 is provided with a positioning opening 41, the first seesaw 5 is connected to the base 2 through the third rotating shaft 14, one end of the first seesaw 5 is connected with the spring 6 and connected with the The bottom of the limiting block 15 is arranged oppositely, the other end of the first seesaw 5 is arranged oppositely to the positioning opening 41, the base 2 is provided with a positioning block 21, and the folding tube 3 is provided with a The top bloc...

Embodiment 2

[0035] combined with Figures 1 to 6 , the technical solution of the present invention is a scooter, comprising a vehicle body 17, a headstock 18 and the folding mechanism described in Embodiment 1, the bracket 4 is connected to the body 17, and the headstock 18 is connected to the headstock bar 1 superior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com