Standardized and automatic preparation device for laboratory concrete test piece

A technology for a concrete specimen and a preparation device, which is applied in the field of mixing equipment, can solve the problems of dirty and messy concrete laboratories, slow preparation speed, and large environmental pollution, and achieves the effects of saving manpower, low cost, and long life cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

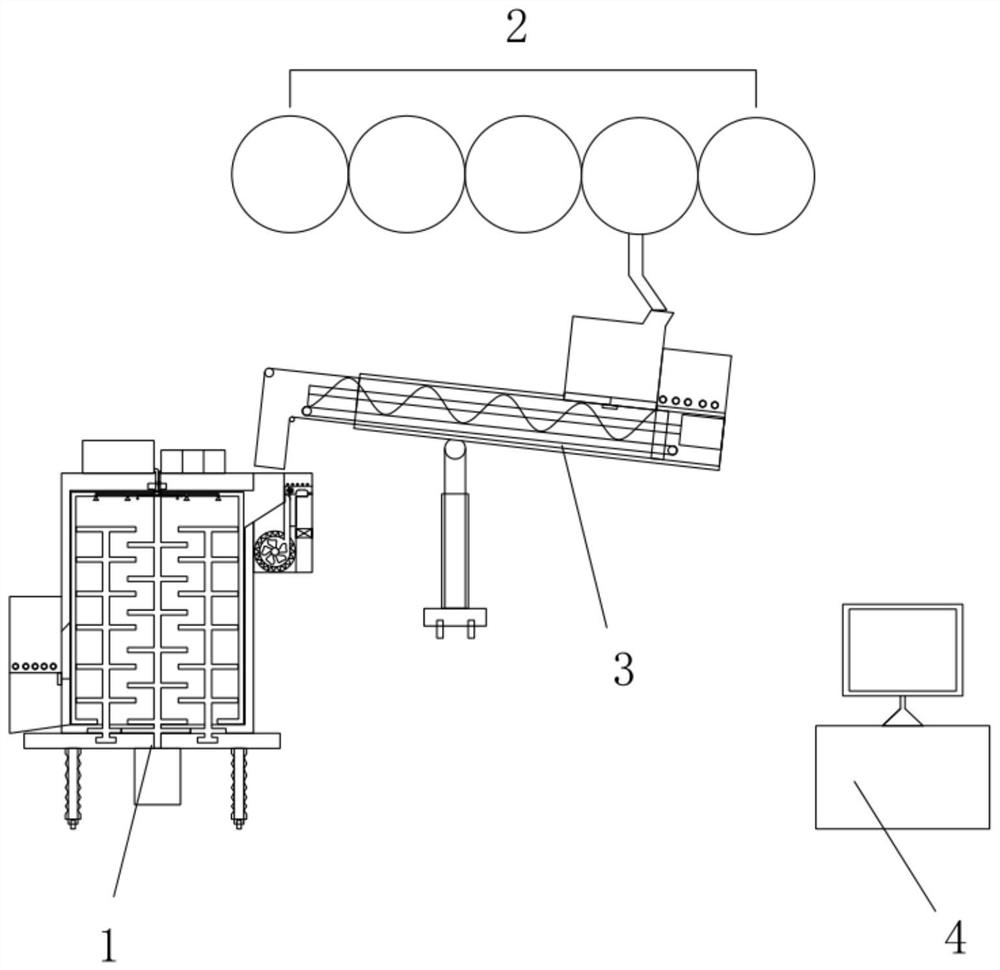

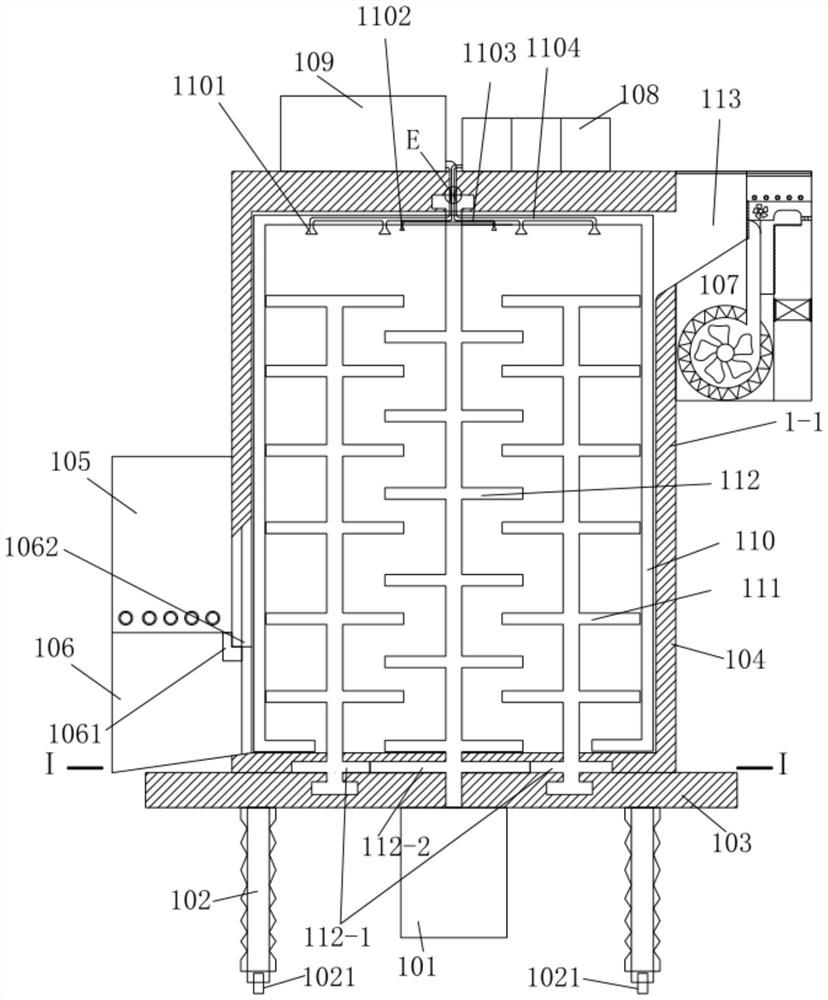

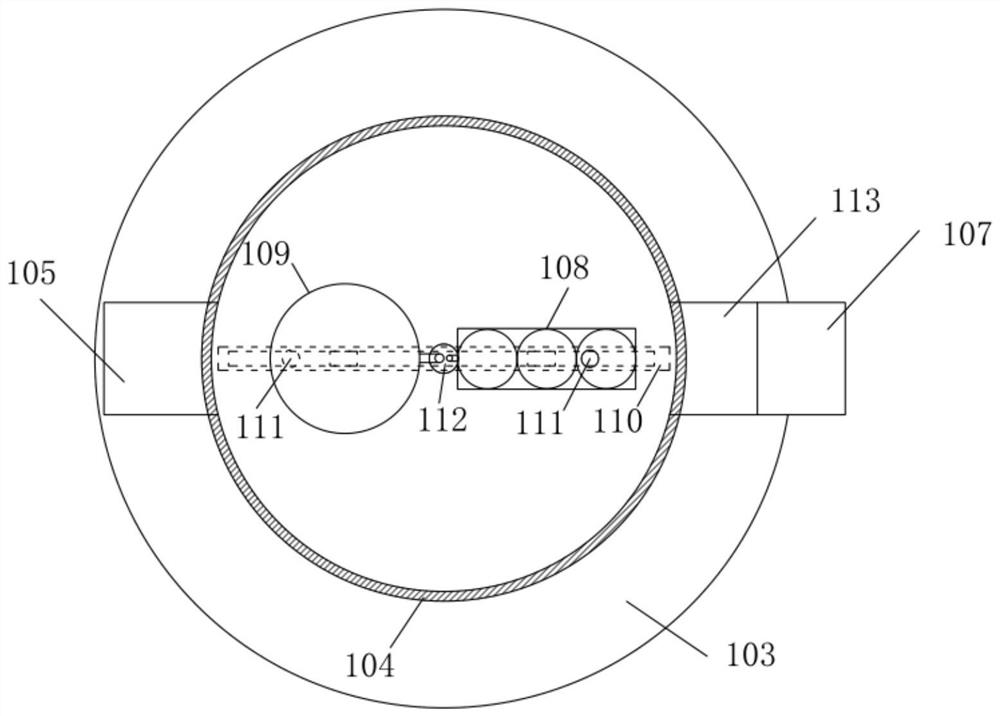

[0038] see Figure 1-Figure 11 , an embodiment provided by the present invention: a laboratory concrete specimen standardization and automatic preparation device, including the following equipment:

[0039] A concrete automatic mixer 1 and a raw material storage tank 2 fixed in the corresponding position of the laboratory according to the laboratory layout and the needs of the experiment;

[0040] The automatic feeder 3 connected between the concrete automatic mixer 1 and the raw material storage tank 2, and is electrically connected with the automatic feeder 3, the concrete automatic mixer 1 and the raw material storage tank 2, and can be mixed according to the corresponding parameters of the required concrete or It is the experimenter's need to control the concrete automatic mixer 1, the raw material storage tank 2, and the automatic feeder 3 to configure the automatic control equipment 4 according to the experiment and corresponding specifications;

[0041] Wherein, the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com