Multi-layer decoration injection mold

A technology for injection molds and concave molds, which is applied in the field of multi-layer decorative injection molds and mold parts. It can solve the problems of complex production process of injection molds, stuck injection products, and long production cycle, so as to ensure the quality and stability of extruded products. Sexuality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

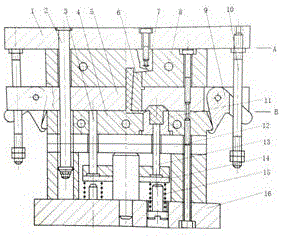

[0015] Embodiment 1: see figure 1 , a multi-layer decorative injection mold, the injection mold includes an upper mold 5, an upper mold bottom plate 1, a lower mold 4, a lower mold bottom plate 16, a feeding chamber 8, a multilayer backing plate 12, a die 11, a push assembly and a fixed From the pull rod 2, the feeding chamber 8 is arranged between the bottom plate of the upper mold and the upper mold, the multi-layer backing plate is arranged between the bottom plate of the lower mold and the lower mold, the pushing assembly is arranged on the bottom plate of the lower mold, and the concave mold 11 is arranged on the multi-layer backing plate, and the distance tie rod is used to position the multi-layer backing plate and the upper mold of the upper mold; the injection mold also includes a sprue sleeve 6 and a pressure column 7, and the sprue sleeve is set On the upper mold, the pressure column is arranged on the bottom plate of the upper mold, the thickness of the multi-layer...

Embodiment 2

[0016] Example 2: see figure 1 , as an improvement of the present invention, the injection mold also includes a pull hook 9, and the pull hook 9 is arranged on the upper mold 5, and the injection mold also includes a pull rod 10, and the pull rod 10 is arranged on the bottom plate of the upper mold, so The number of said pull rods is two. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0017] Embodiment 3: see figure 1 , as an improvement of the present invention, the push assembly further includes a push rod 13, a push plate 14 and a spring 15, the push rod is set on the push plate, and the push plate is set on the spring. The rest of the structures and advantages are exactly the same as in Embodiment 1.

[0018] Work process: see figure 1 , when working, install the mold on an upper-press type press for use. When the mold is opened, the press drives the bottom plate 1 of the upper mold to rise, that is, the mold is divided from the A surface, so that the pressure column 7 leaves the feeding chamber with the main channel condensate , when the bottom plate of the upper mold is opened for a distance S, the nut on the pull rod 10 contacts with the pull hook 9 fixed on the upper template 5 and can rotate around the axis, so that the pull hook is disengaged from the lower mold 4. At this time, due to the fixed distance pull rod 2 Pull the upper mold 5 to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com