An assembly device for the roller pressure bar of a roller-type collodion mop

A collodion mop and assembly device technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of backward assembly process, unfavorable mass production and high cost, and achieve low production efficiency, reduce labor costs and save money. The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

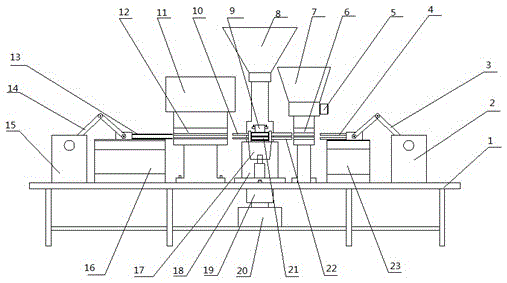

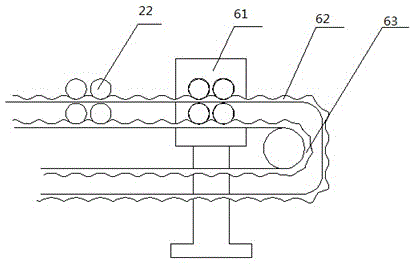

[0012] like figure 1 As shown, the assembly device of the roller pressure rod of the roller type collodion mop includes a workbench 1, a roller pressure rod propulsion motor unit 2, a roller pressure rod crank-link slider mechanism 3, a roller pressure rod push rod 4, an oscillating motor 5, a side End roller pressure bar conveyor belt 6, side end roller pressure bar hopper 7, internal roller pressure bar hopper 8, manipulator 9, fixed bar 10, fixed bar hopper 11, fixed bar conveyor belt 12, fixed bar push rod 13, fixed bar crank Link slider mechanism 14, fixed bar propulsion motor unit 15, fixed bar slide rail device 16, mop fork 17, clamp 18, 180° indexing plate rotation mechanism 19, motor box 20, internal roller pressure rod 21, side end Roller pressing bar 22, roller pressing bar slide rail device 23; The roller pressing rod pushes the rotating shaft of the motor unit 2, and drives the slider to reciprocate linear motion on the roller pressing bar slide rail device 23, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com