Polymerizer polishing device

A polishing device and polymerization kettle technology, applied in the field of mechanical devices, can solve problems such as personal accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

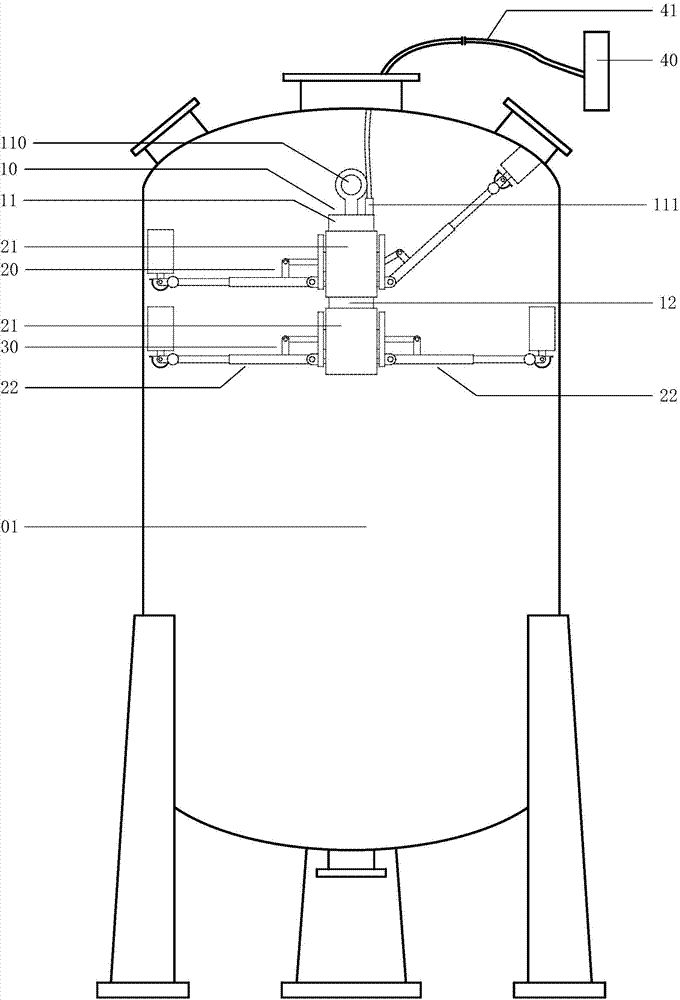

[0019] In factories producing chemical raw materials, various polymerization kettles 01 are widely used. Polymerization kettles 01 include vertical kettles and horizontal kettles. This embodiment is suitable for use in conjunction with vertical kettles. The vertical kettle is installed in the production plant matching the polymerization kettle 01 and has a kettle mouth on the top, and a lifting hook is provided in the production workshop above the kettle mouth. When the material sticks to form wall scale on the inner wall of the polymerization kettle 01 and affects production, the operator first opens the mouth of the kettle, and then lifts this embodiment into the inner cavity of the kettle by a lifting hook for polishing, so that the wall scale can be removed.

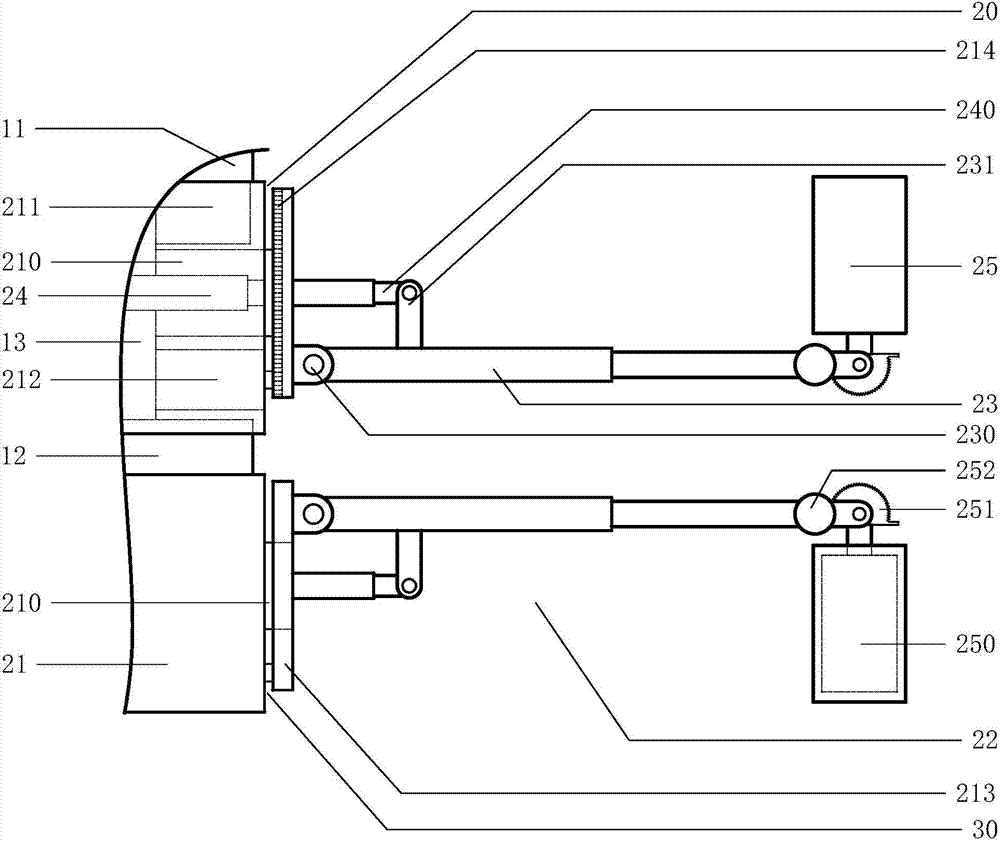

[0020] see figure 1 and combine figure 2 The grinding and polishing device for the polymerization kettle of the present embodiment includes a comprehensive base frame 10, an upper kettle wall grinder 20, a lower ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com