Code printing system, method and device

A coding lens and position information technology, applied in the field of coding systems, can solve the problems of ID code deviation from the coding position frame, poor coding accuracy and coding process stability, economic losses of manufacturers, etc., to improve stability, monitor The effect of reducing management difficulty and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

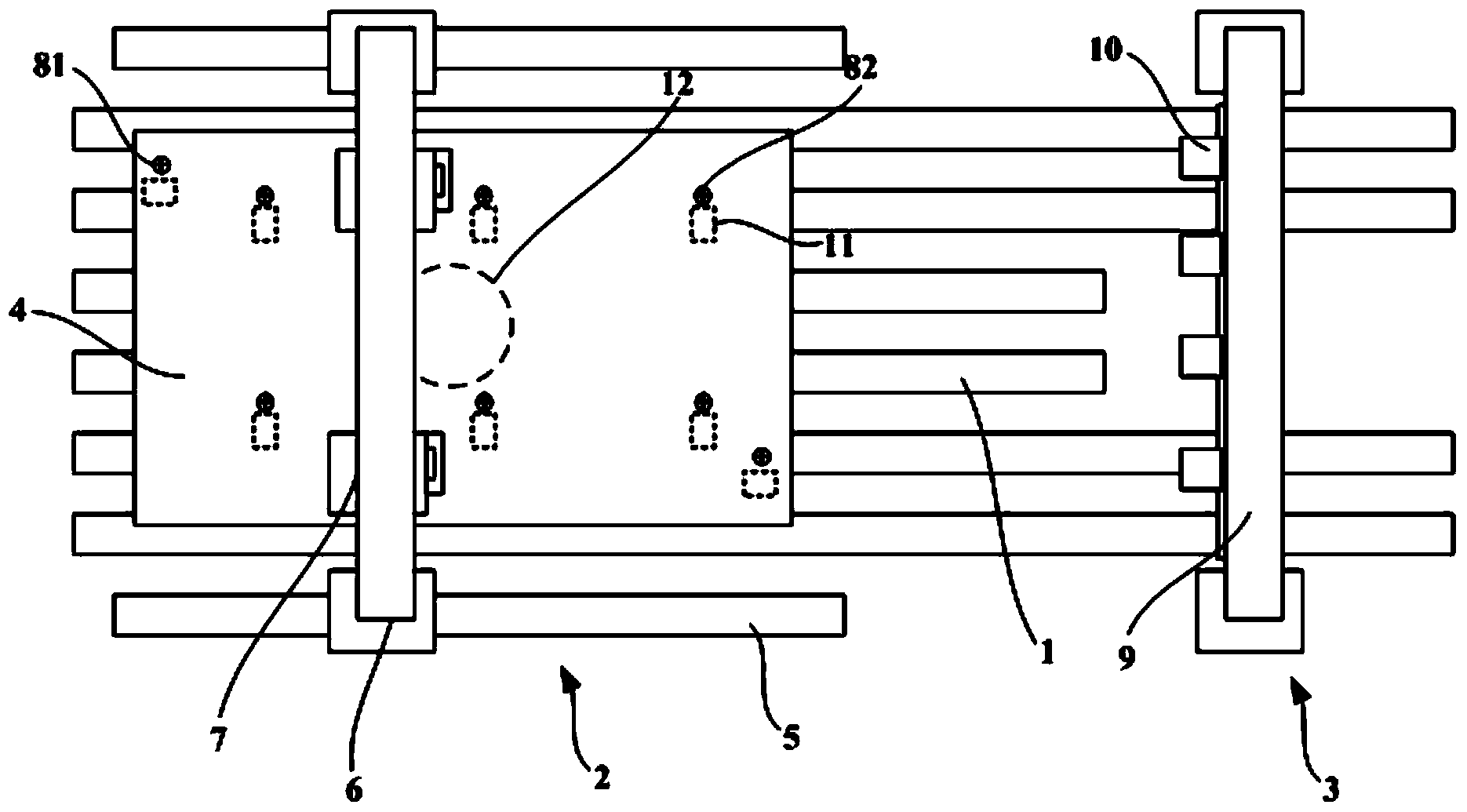

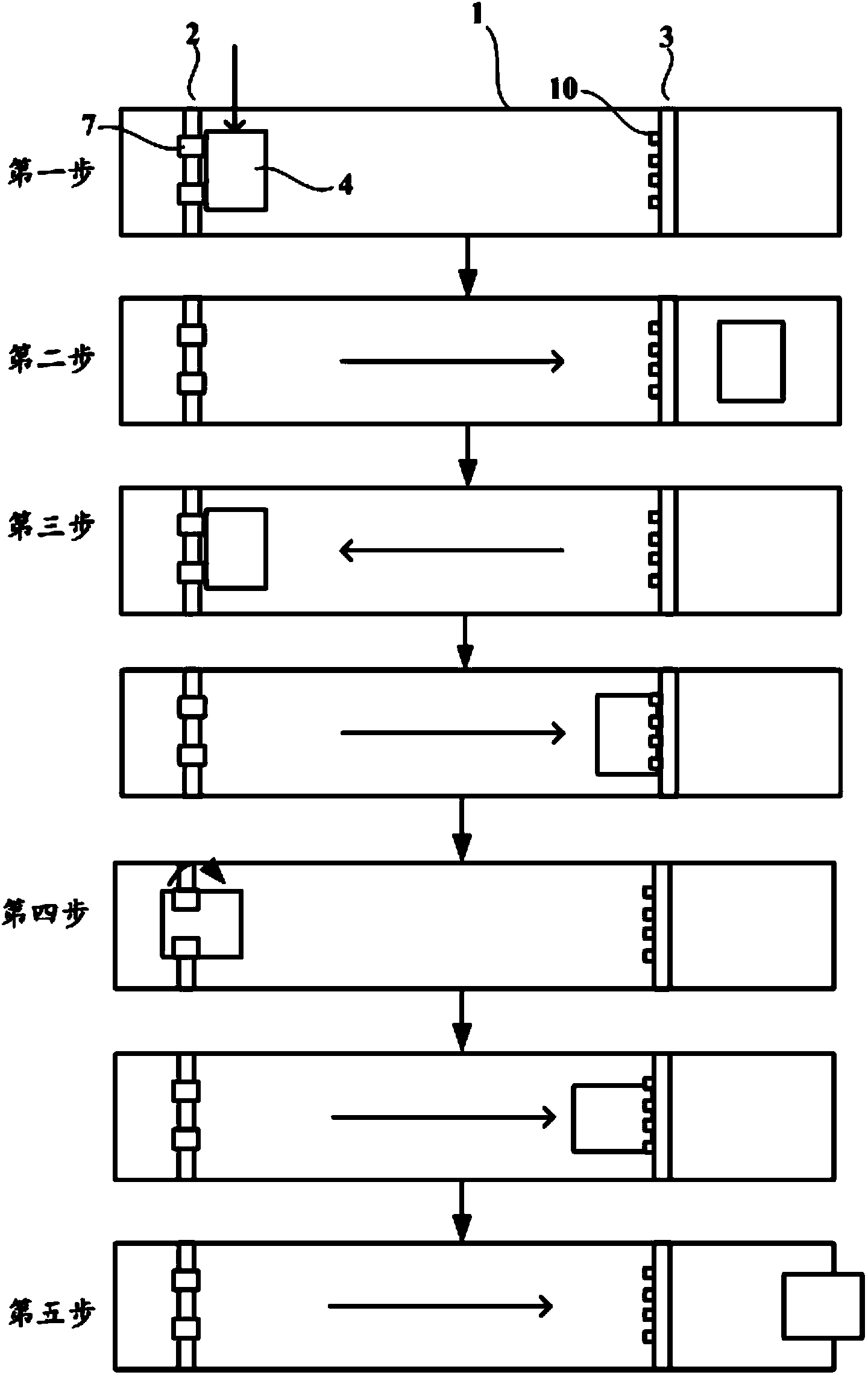

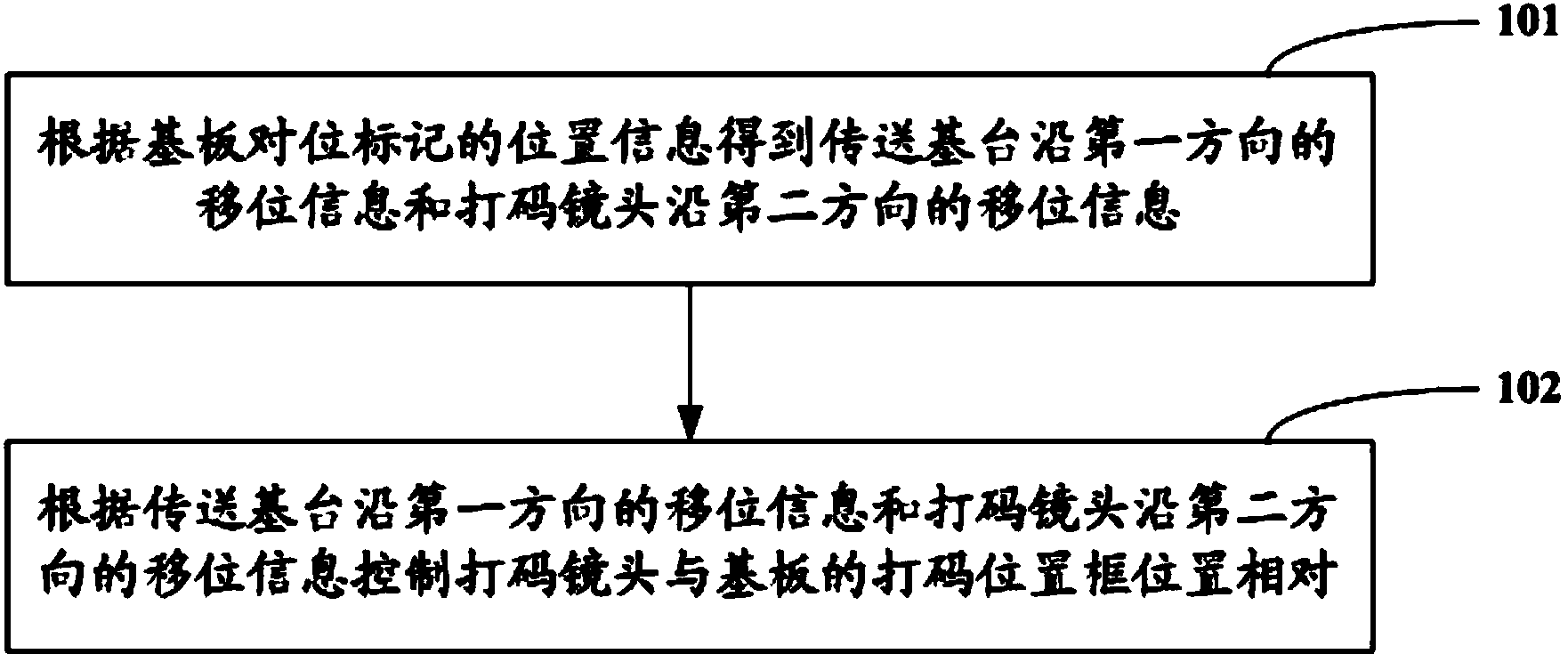

[0036] In order to improve the coding accuracy and the stability of the coding process, and reduce the difficulty of product monitoring and management, the embodiments of the present invention provide a coding system, method and device. In the technical solution of the present invention, the alignment lens collects the position information of the substrate alignment mark, and the control device obtains the displacement information of the transmission base along the first direction and the displacement information of the coding lens along the second direction according to the position information of the substrate alignment mark. Shift information; according to the shift information of the transmission base station along the first direction and the shift information of the coding lens along the second direction, the position of the coding lens is controlled relative to the coding position frame of the substrate. Compared with the prior art, the marking The code position is determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com