Trash can ventilation device

A ventilation device and trash can technology, applied in the field of trash cans, can solve the problems of air pollution in trash cans, unfavorable environmental beautification, and troubles for surrounding residents, and achieve the effects of environmental protection, easy manufacture, and good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

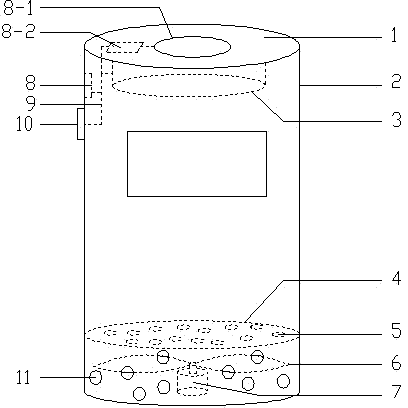

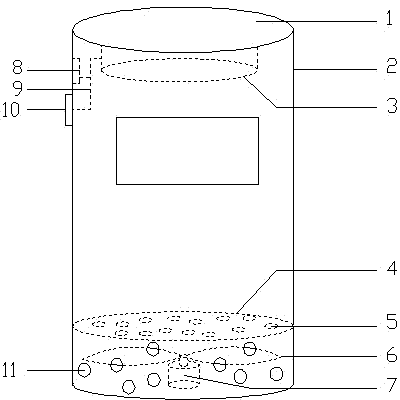

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] Such as figure 1 and figure 2 Shown, a kind of dustbin ventilating device of the present invention comprises bucket body 2, and the bung 1 that is installed on the bucket body 2 also includes power supply, power switch 10, fan blade 6, motor 7, leaking layer 4; Power supply is installed on Inside the barrel body 2, the power switch 10 is installed on the outside of the barrel body 2, the fan blade 6 is installed on the motor 7 through the shaft, the motor 7 is installed on the bottom of the barrel body 2, the water leakage layer 4 is arranged on the top of the fan blade 6, and is installed on the barrel body 2 Inside, the water leakage layer 4 has the same diameter as the barrel body 2; the power switch 10 and the motor 7 are electrically connected to the power supply through the wire 9.

[0022] As an improvement of the present invention, the power supply is a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com