Efficient negative pressure cereal loading machine

A negative pressure, grain technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of easily damaged grain surface, high noise, low efficiency, etc., to save cleaning time, low noise, and small damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

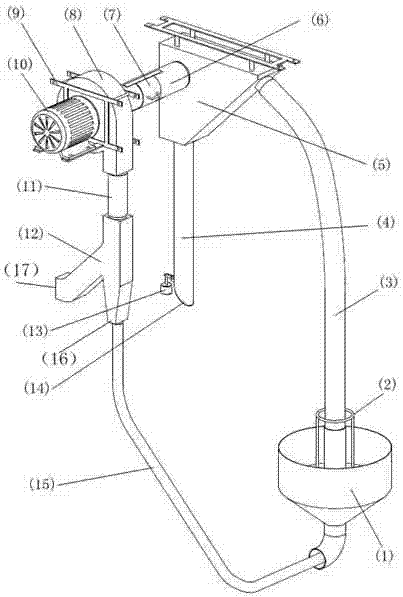

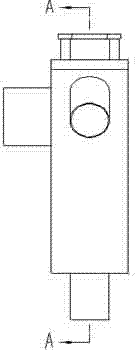

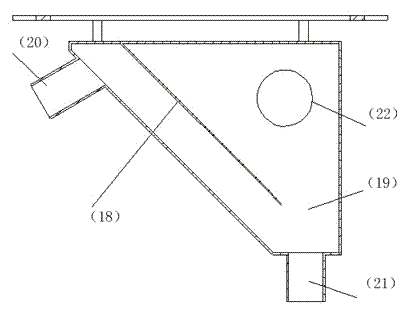

Embodiment 1

[0017] Embodiment 1 of the present invention: a high-efficiency negative pressure grain feeding machine, as shown in the accompanying drawings, includes a hopper 1, a feeding pipe 3 is connected to the feeding port of the hopper 1, and a feeding pipe 3 is connected between the hopper 1 and the feeding pipe 3. There is a feed adjustment switch 2 between them, and the other end of the feeding pipe 3 is connected to the feed inlet at the upper end of the transition chamber 5. A channel, the baffle plate at the discharge port and the transition chamber 5 form a through hole 19, which can be communicated with the air outlet of the transition chamber 5, and the vertical storage pipe 4 is arranged at the discharge port at the bottom of the transition chamber 5 , there is a discharge door 14 at the outlet of the discharge pipe 4, the discharge door 14 is connected with the counterweight 13 through a lever, the suction pipe 6 is arranged at the air outlet on one side of the transition c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com