Pull-up device for spinning bobbin

A bobbin and textile technology, which is applied in the field of pulling devices for textile bobbins, can solve the problems of reducing work efficiency and difficult to pull out the bobbins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

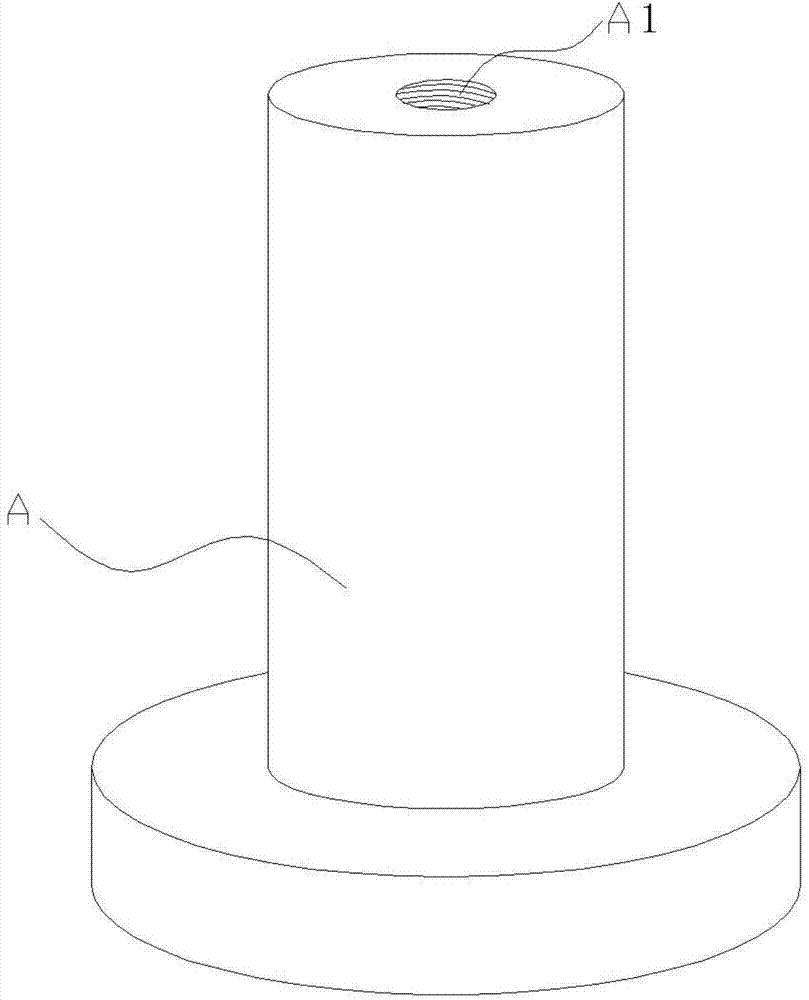

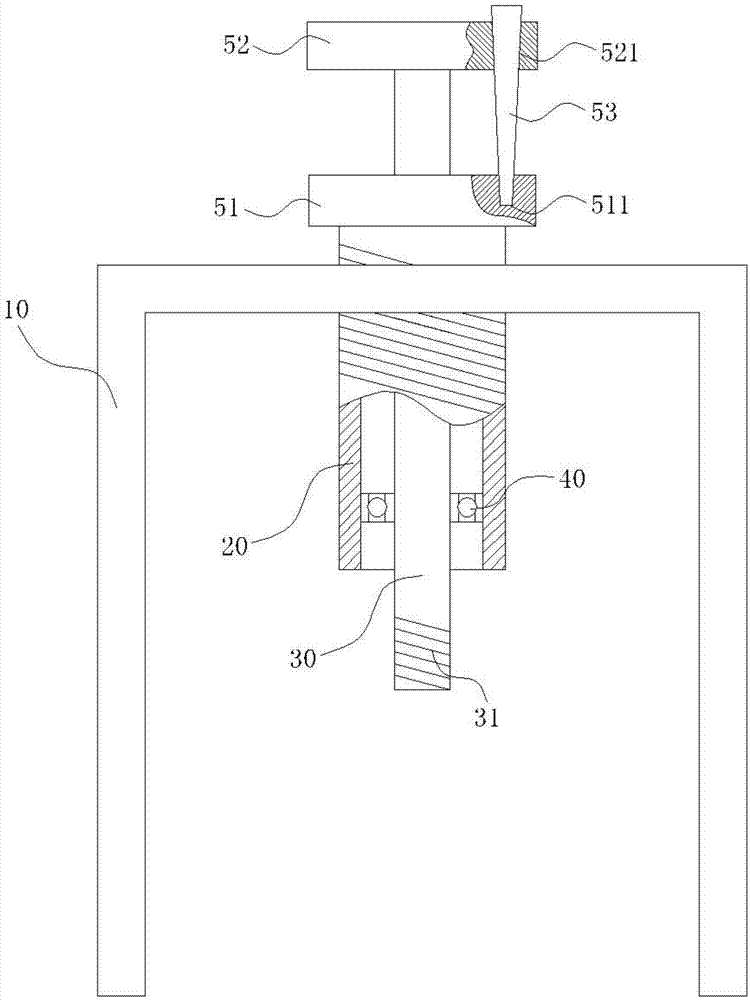

[0027] Such as Figure 1~3 As shown, a pull-up device for a textile bobbin includes a bracket 10 that can cover the bobbin A, a spiral tube 20 threaded with the bracket 10, a screw rod 30 installed in the spiral tube 20, the spiral tube 20 and The screw rods 30 are connected together by a bearing 40, and one end of the screw rod 30 is provided with a screw thread 31 matched with the screw hole A1 on the top of the bobbin tube A, and the screw thread 31 has the same rotation direction as that on the spiral tube 20, One end of the screw rod 30 protrudes from the spiral tube 20 for a certain distance, and the other end of the screw rod 30 is installed with a locking device for locking and disassembling the screw rod 30 and the spiral tube 20 . Wherein, the direction of rotation of the thread 31 is left-handed or right-handed.

[0028] The locking device includes a fixed block 51 installed on the end of the spiral tube 20, a fixed block 52 installed on the end of the screw rod 30...

Embodiment 2

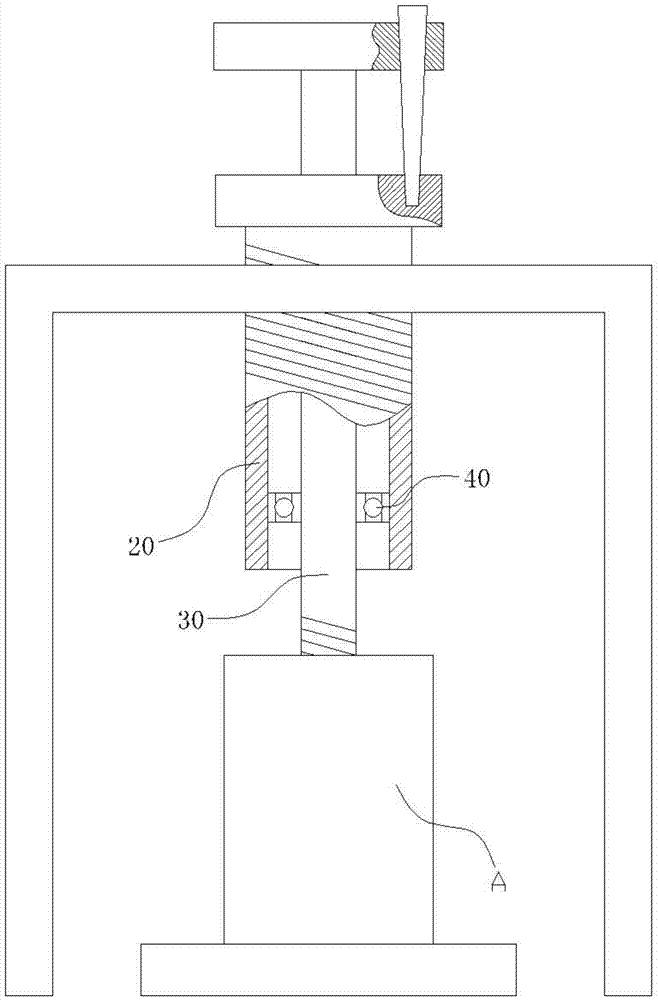

[0030] Such as figure 1 , 4 As shown in ~7, a pull-up device for a textile bobbin includes a bracket 10 that can cover the bobbin A, a spiral tube 20 threaded with the bracket 10, and a screw rod 30 installed in the spiral tube 20. The spiral tube 20 and the screw rod 30 are connected together through a bearing 40. One end of the screw rod 30 is provided with a screw thread 31 matched with the screw hole A1 on the top of the bobbin tube A. Similarly, one end of the screw rod 30 extends out of the spiral tube 20 for a certain distance, and the other end of the screw rod 30 is installed with a locking device for locking and disassembling the screw rod 30 and the spiral tube 20 . Wherein, the direction of rotation of the thread 31 is left-handed or right-handed.

[0031] The locking device includes a movable block 54 with a square through hole 541 in the central position, and a fixed block 55 installed at the end of the spiral tube 20. The movable block 54 is provided with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com