A hydraulic cylinder assembly spreader

A hydraulic cylinder and spreader technology, which is applied in the field of hydraulic cylinder assembly, can solve the problems that it is difficult for the cylinder liner and cylinder assembly to be precisely concentric up and down, the surface of the outer cylinder is easy to be strained, and the support does not have the function of aligning, etc., to achieve The effects of shortening the assembly operation time, enhancing the automatic centering function, and increasing the centering range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

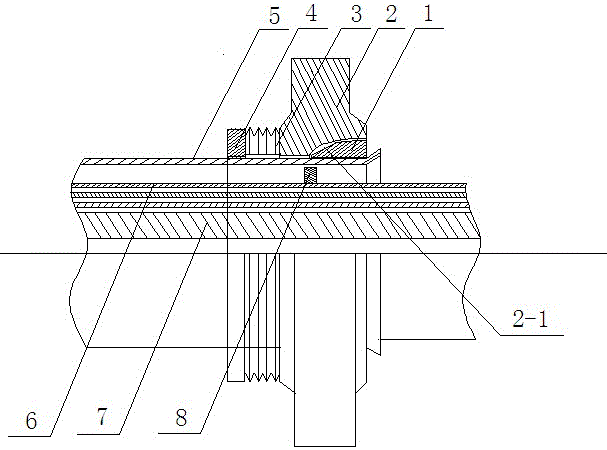

[0017] Such as figure 1 As shown, the hydraulic cylinder assembly spreader of the present invention includes a spreader body 2 and a support body 1, and the spreader body 2 and the support body 1 are both provided with through holes for wearing the cylinder liner 5 of the hydraulic cylinder. The support body 1 is spherically matched with the spreader body 2, that is, one end of the spreader body 2 is provided with a spherical groove, and one end of the support body 1 is a spherical structure with a radius similar to that of the spherical groove. Free relative to the spherical rotation. In this way, when the hoisted cylinder liner 5 is misaligned with the axis of the cylinder assembly, the support body can automatically adjust the center, so that the cylinder liner 5 remains coaxial with the cylinder assembly, preventing the surface of the outer cylinder 6 from being bumped and strained. In order to ensure that the support body 1 has a large degree of freedom of rotation and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com