Rotating mechanism of gate seat type crane

A portal crane and slewing mechanism technology, applied in cranes and other directions, can solve the problems of increasing friction, reducing the working stability of moving parts, shortening the service life of parts, etc., to achieve the effect of improving work efficiency, avoiding unilateral wear, and moving smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

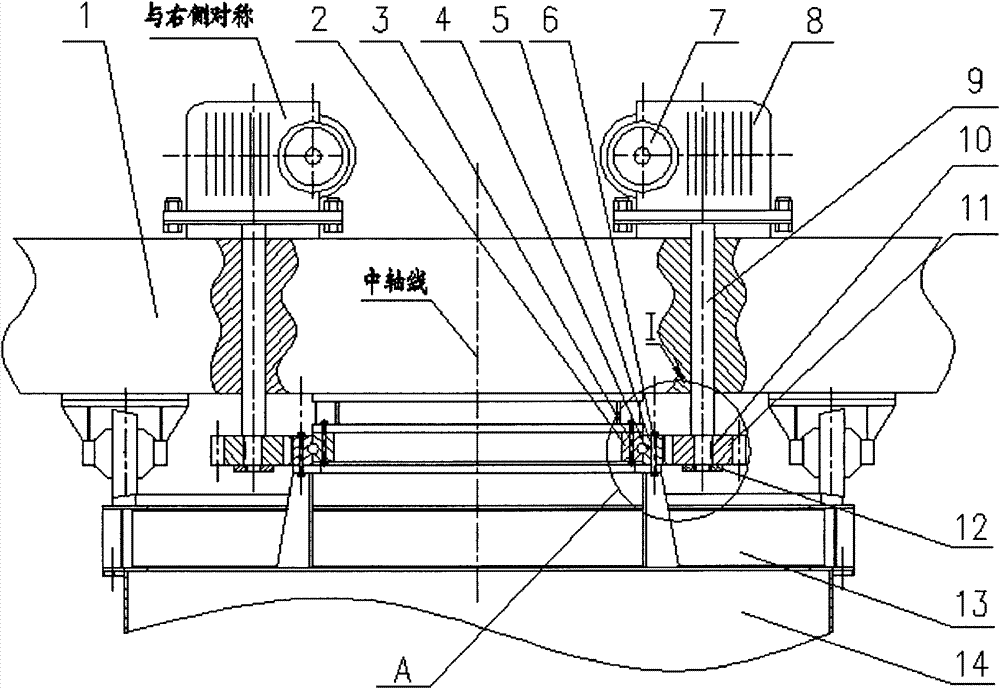

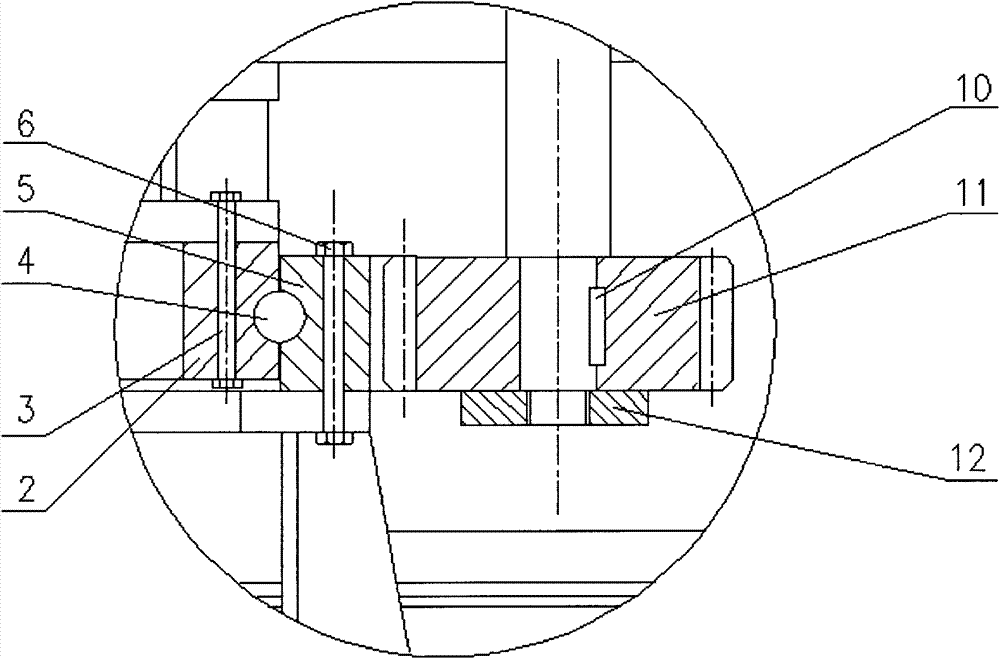

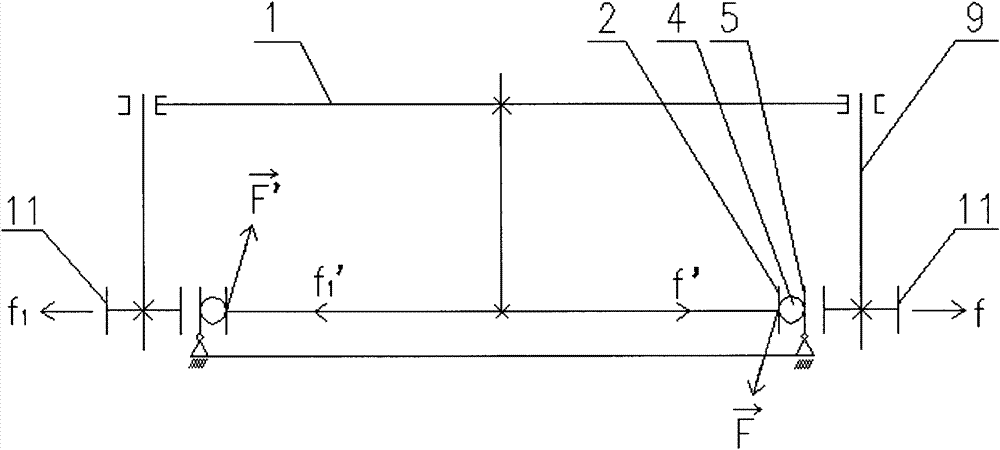

[0021] exist figure 1 Among them, the motor 7 drives the reducer 8, the transmission gear shaft 9 and the transmission gear 11 fixed on the transmission gear shaft 9 through the flat key 10 and the lock nut 12 to rotate, and the slewing ring meshing with the transmission gear 11 passes through the outer ring Fastening screw 6 is fixed on the circular chassis 13 that links to each other with base 14, can't rotate, so transmission gear 11 both has self-rotation, must do circular motion again around slewing ring ring gear. At the same time, the base of the reducer 8 is welded on the slewing platform 1, and the inner ring 2 of the slewing bearing is connected to the bottom of the slewing platform 1 through the inner ring fastening bolt 3, so all parts connected to the slewing platform 1 are rotated around Support the circular motion of the large ring gear 5. At the same time, a steel ball 4 is installed between the large ring gear 5 of the slewing ring and the inner ring 2 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com