An electric maintenance station sliding chair convenient for high-altitude operation and its use method

A technology for power maintenance and high-altitude operations, which is applied in the direction of overhead lines/cable equipment, cable railways, motor vehicles, etc. It can solve problems such as center of gravity deviation, inconvenient operation, and reduced maintenance efficiency, so as to avoid unilateral wear, ensure safety, and Ease of maintenance operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

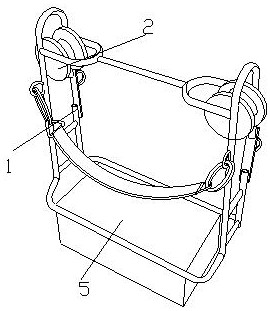

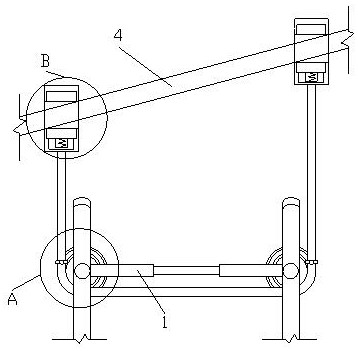

[0016] as attached Figures 1 to 5 As shown in the figure, a power maintenance station-type slide chair that is convenient for high-altitude operations includes a mounting frame 1, a pulley 2, a slide rail rope 4 and a rotating shaft 6, and two pulleys are rotatably installed on the mounting frame 1 through the rotating shaft 6 2. The rotating shaft 6 is fixed by the bearing 7 , and the sliding rope 4 is provided above the pulley 2 .

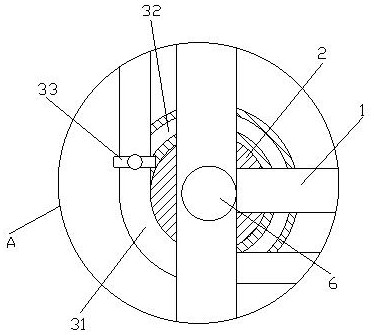

[0017] as attached Figures 2 to 5 As shown, there is also an auxiliary mechanism 3 assembled on the outside of the pulley 2. The auxiliary mechanism 3 includes an auxiliary rope 31, a chute 32, an anti-derailment mechanism 33 and a positioning mechanism 34. The mechanism 33 and the pulley 2 can be slidably installed on the outside of the auxiliary rope 31, and the two anti-derailment mechanisms 33 are respectively arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com