Central plate link chain of chain bucket type hoister

A hoist and central technology, applied in the field of component structure of transportation machinery, can solve the problems of unloading, low chain speed of NE plate chain, etc., and achieve the effect of uniform wear, small wear amount and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

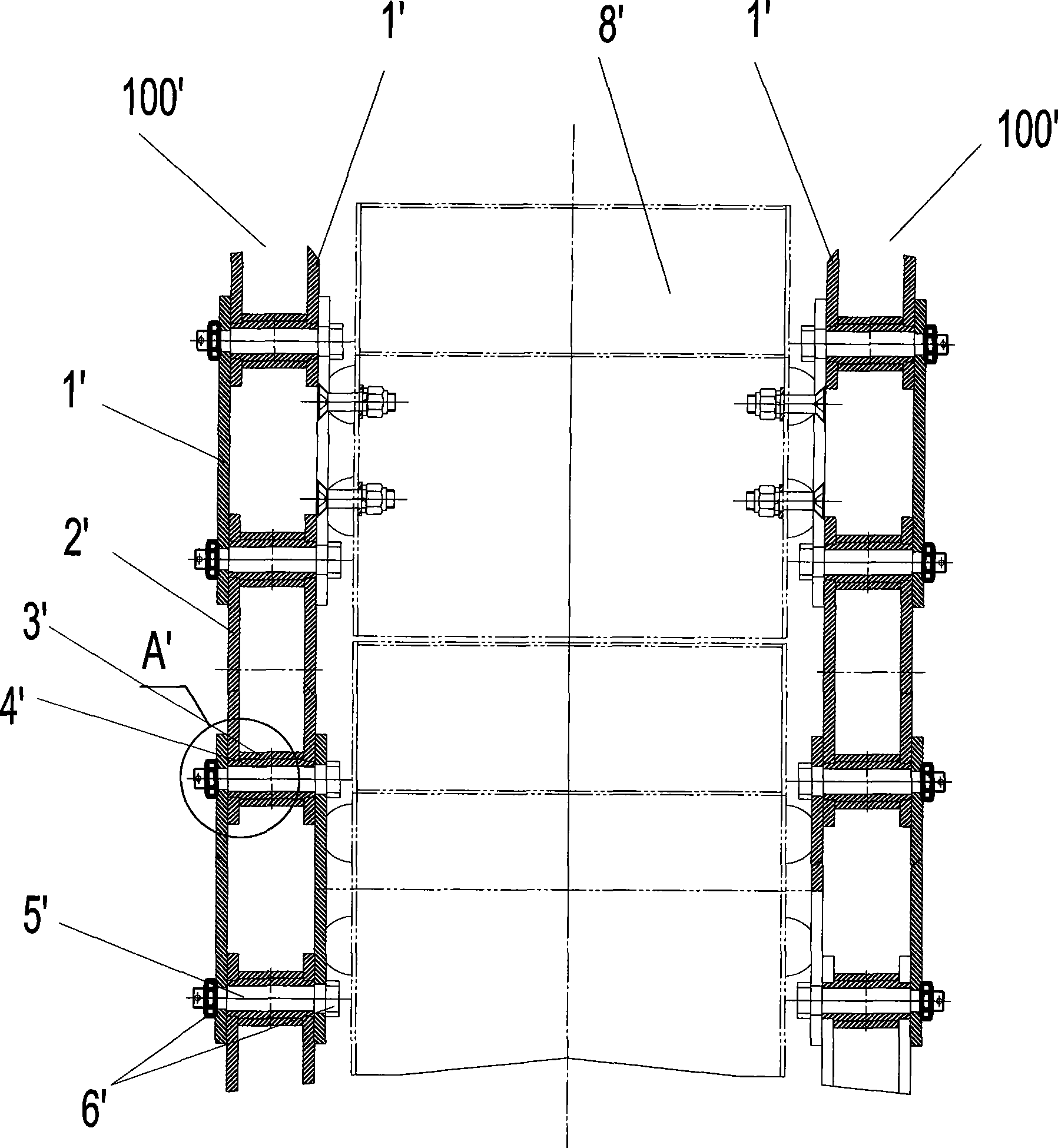

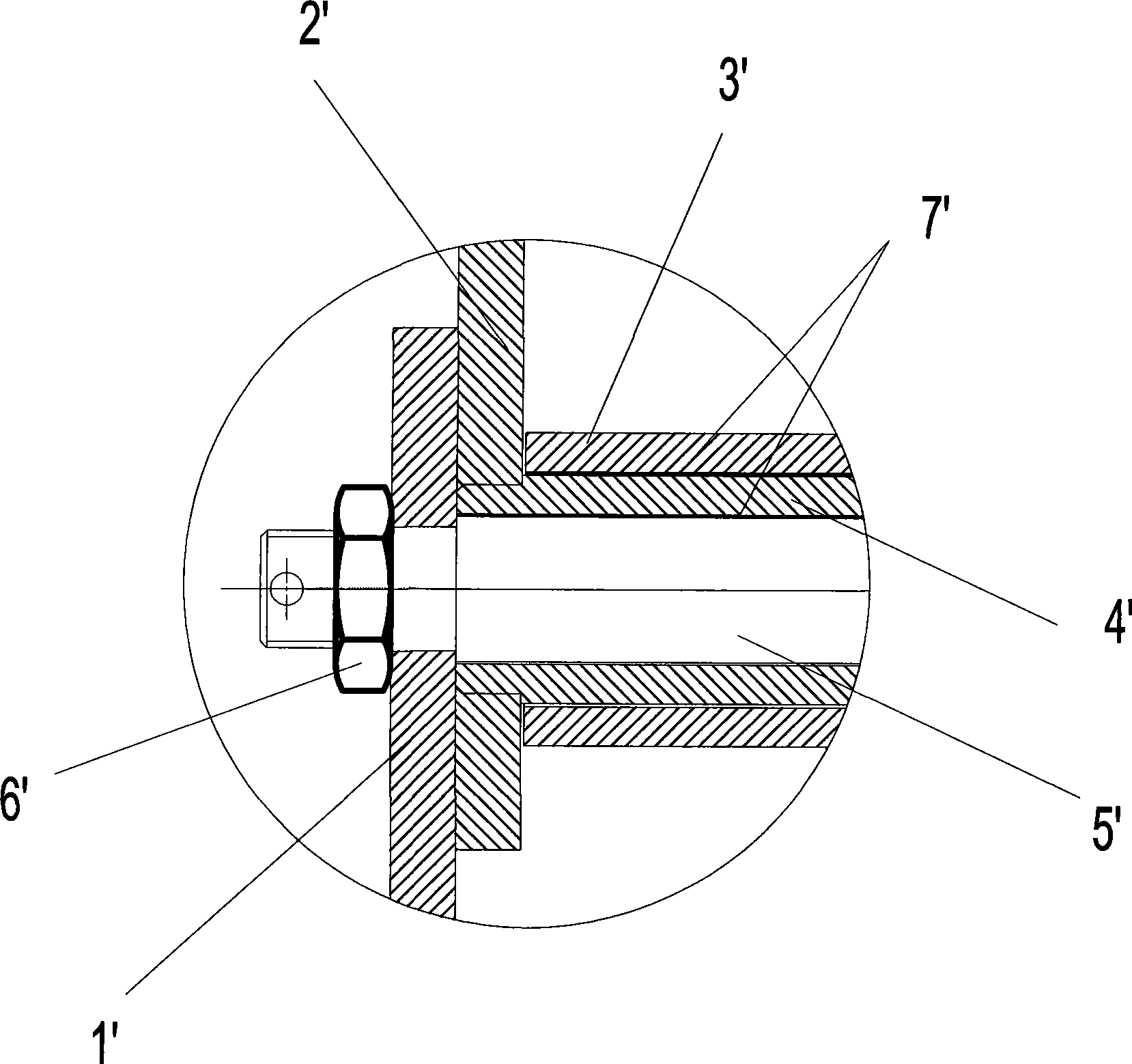

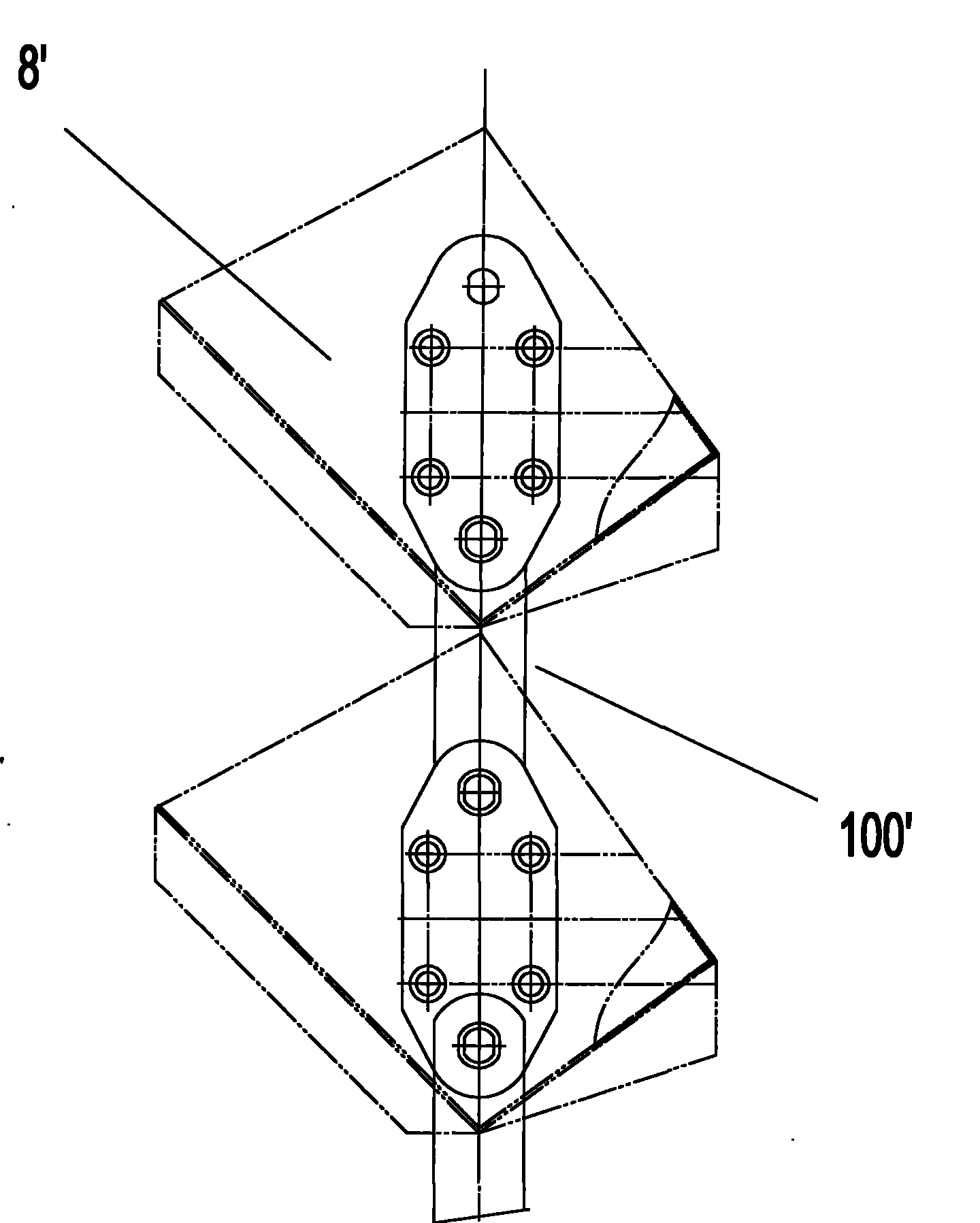

[0020] Such as Figure 4 , Figure 5 As shown, the central sleeve 3 is sleeved with a clearance fit in the middle of the mandrel 5 of the present invention, and the two sides of the middle sleeve 3 have side sleeves 4 with the same inner and outer diameters as the middle sleeve 3 and are sleeved on the mandrel 5 with a clearance fit. , that is, the mandrel 5 can freely rotate 360° in the middle sleeve 3 and the side sleeve 4 .

[0021] An outer link plate 1 is provided in the interference fit sleeve on each side sleeve 4, and an inner link plate 2 is provided in the interference fit sleeve at both ends of the middle sleeve 3, and both ends of the outer link plate 1 and the inner link plate 2 have steps. Pivoted in the middle of the outer chain plate 1, the T-shaped cross-section limit chuck 6 on the inner side of the outer chain plate 1 presses the inner chain plate 2 on both sides of the limit chuck 6 and connects with the step at the end of the inner chain plate 2. Cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com