Jacking structure during closestool sintering

A toilet and jacking technology, which is applied in the field of sanitary ware production, can solve the problems of waste, waste of fuel costs, and difficulty in recycling heat energy, etc., and achieve the effects of less heat-absorbing mass, lower energy consumption, and significant energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. It should be noted that the accompanying drawings are only for illustrating the structure of the present invention, and are not strictly drawn to scale. It should be noted that the drawings are only for illustrative purposes and are not drawn to a strict scale, and there may be partial enlargements and reductions for the convenience of description, and there may be certain omissions for some known structures.

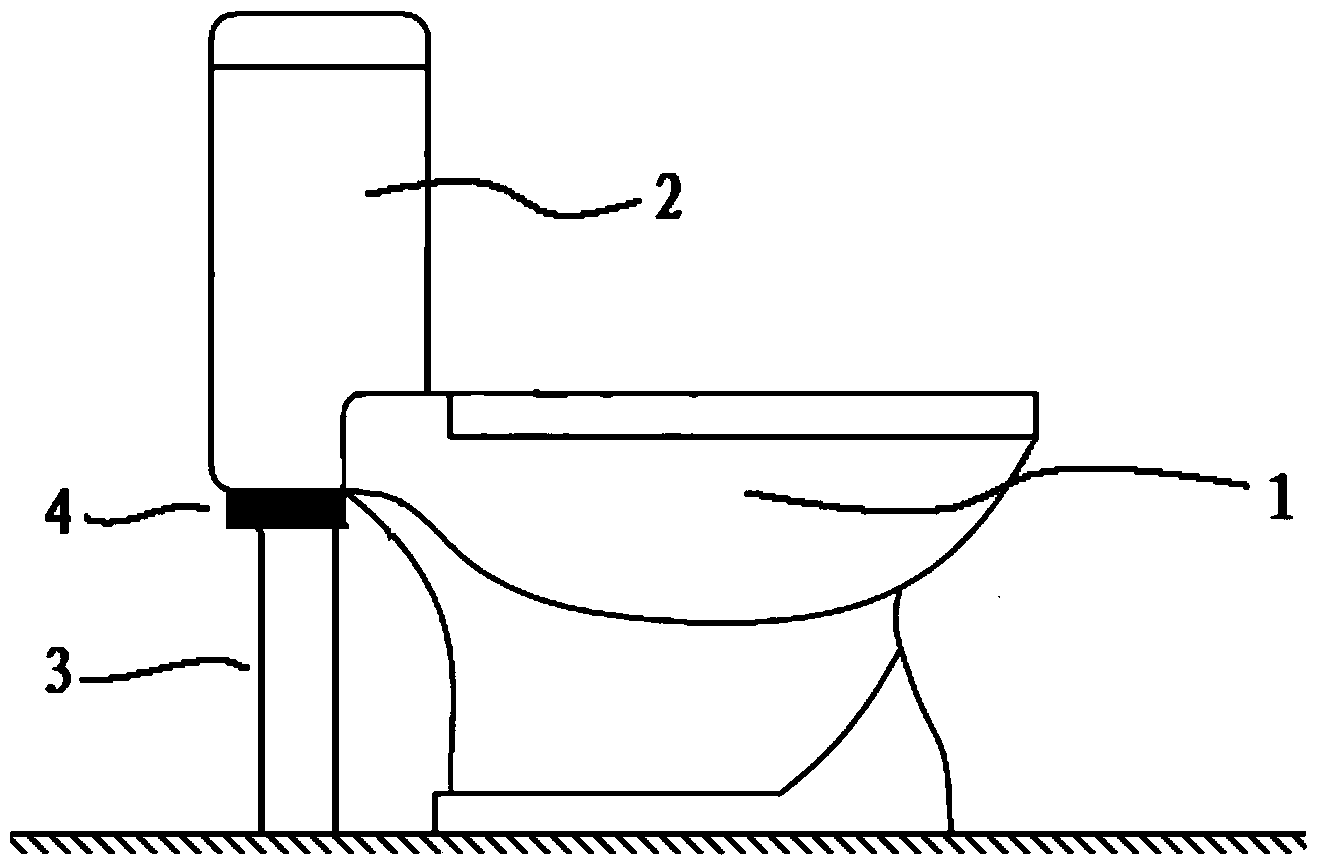

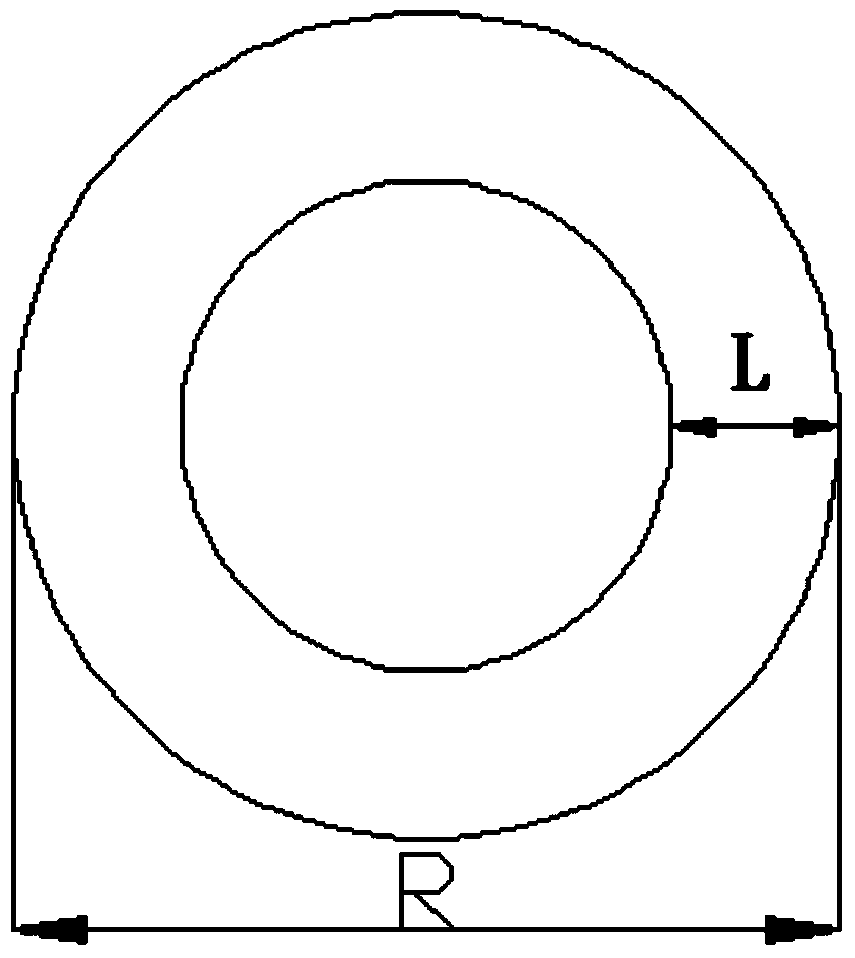

[0017] refer to figure 1 , figure 1 It is a schematic diagram of the fired jacking structure of the toilet provided by the present invention. A toilet fired jacking structure, which includes a hollow ceramic column 3 and a burnt-out material 4, the hollow ceramic column 3 is placed under the water tank 2 of the toilet blank 1, and the burnt-out material 4 is placed on the hollow ceramic colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com